Stirring method for negative electrode of lithium ion batteries, application of stirring method, and lithium ion battery

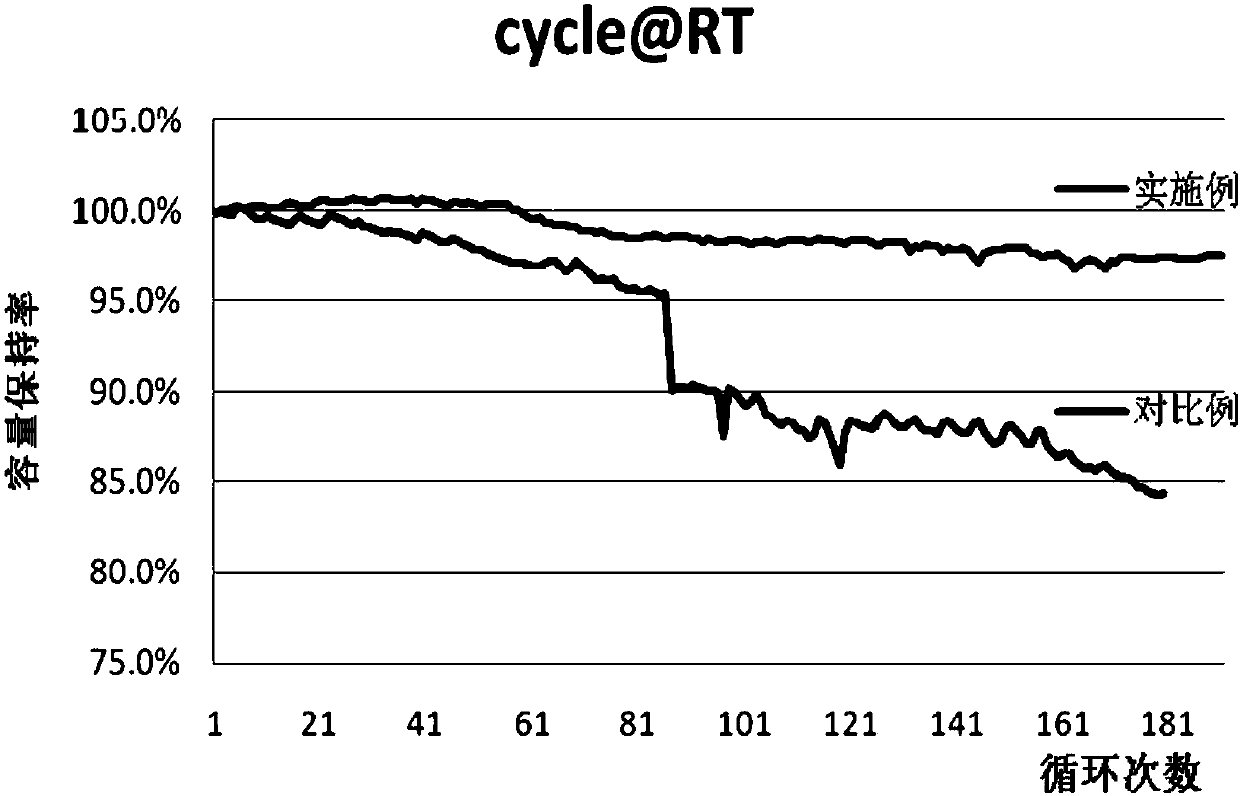

A lithium-ion battery and stirring method technology, which is applied to mixing methods, mixer accessories, chemical instruments and methods, etc., can solve problems such as poor stirring uniformity, and achieve the effects of overcoming poor uniformity, improving battery cycle performance, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

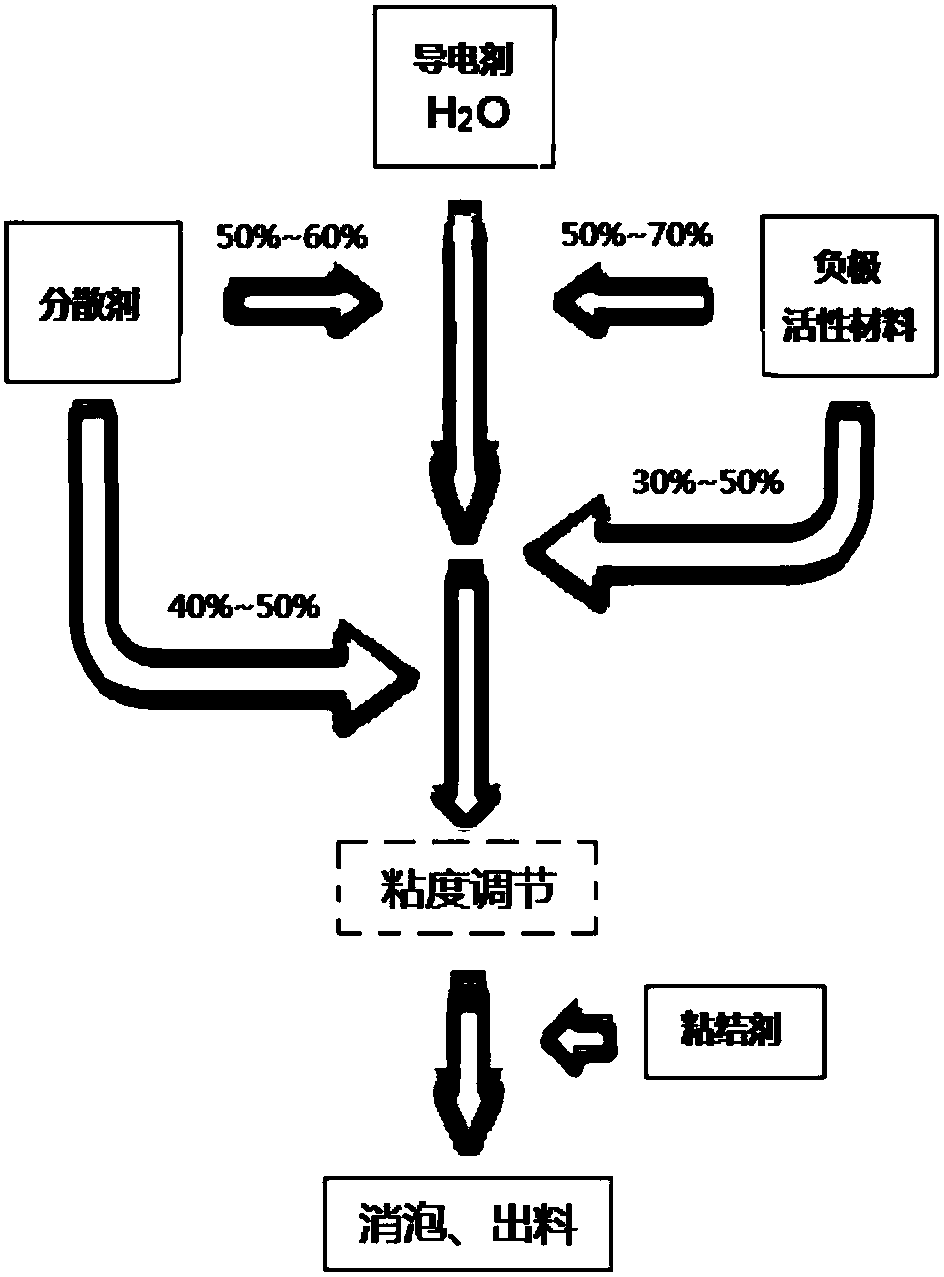

[0034] The lithium-ion battery negative electrode stirring method of the present embodiment may include:

[0035] Step 1: According to the set lithium-ion battery negative electrode formula, based on the amount of each component set, the conductive agent is added to the solvent for pre-stirring (for example: the conductive agent is added to deionized water for pre-stirring ), while pre-stirring the dispersant.

[0036] For example: while the conductive agent and the solvent are pre-stirred, the dispersant is pre-stirred.

[0037] In an optional example, in the step 1, adding the conductive agent to the solvent for pre-stirring may include: first stirring at a speed of 10 rpm and / or rotating at a speed of 100 rpm until After the dry powder of the conductive agent is completely soaked in the solvent, it is scraped; after the scraping is completed, it is rotated at a speed of 20 rpm and / or rotated at a speed of 1000 rpm, and stirred for 60 minutes. By first stirring at a low spee...

Embodiment 2

[0079] Different from the above-mentioned embodiments, the lithium-ion battery negative electrode stirring method of this embodiment may include:

[0080] In step 1, adding the conductive agent into the solvent for pre-stirring may include: first stirring at a speed of 30 rpm and / or rotating at a speed of 500 rpm until the dry powder of the conductive agent is completely soaked in the After being immersed in the solvent, scraping is carried out; after the scraping is completed, it is stirred for 90 minutes by revolving at a speed of 50 rpm and / or rotating at a speed of 2500 rpm.

[0081] Optionally, when adding the conductive agent into the solvent for pre-stirring, and stirring at a speed of 30 rpm and / or rotating at a speed of 500 rpm, the stirring time is 30 min.

[0082] In an alternative example, when the conductive agent is added into the solvent for pre-stirring, when the stirring is carried out for 90 minutes, a vacuum setting is performed so that it is in a vacuum sta...

Embodiment 3

[0093] Different from the above-mentioned embodiments, the lithium-ion battery negative electrode stirring method of this embodiment may include:

[0094] In step 1, adding the conductive agent to the solvent for pre-stirring may include: first stirring at a speed of 20 rpm and / or rotating at a speed of 300 rpm until the dry powder of the conductive agent is completely After immersing in the solvent, scraping is performed; after the scraping is completed, it is rotated at a speed of 35 rpm and / or rotated at a speed of 1750 rpm, and stirred for 75 minutes.

[0095] Optionally, when adding the conductive agent into the solvent for pre-stirring, and stirring at a revolution speed of 20 rpm and / or autorotation at a speed of 300 rpm, the stirring time is 20 min.

[0096] In an alternative example, when the conductive agent is added into the solvent for pre-stirring, when the stirring is carried out for 75 minutes, a vacuum setting is performed so that the following steps 2 to 6 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap