Tile type roof waterproof heat-insulating binding mortar and preparation method thereof

A bonding mortar and tile-type technology, which is applied in the field of waterproof and thermal insulation bonding mortar, can solve problems such as cracking and water seepage of the mortar bonding layer, lack of thermal insulation function, and unstable mortar quality, so as to improve constructability, facilitate industrial production, Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

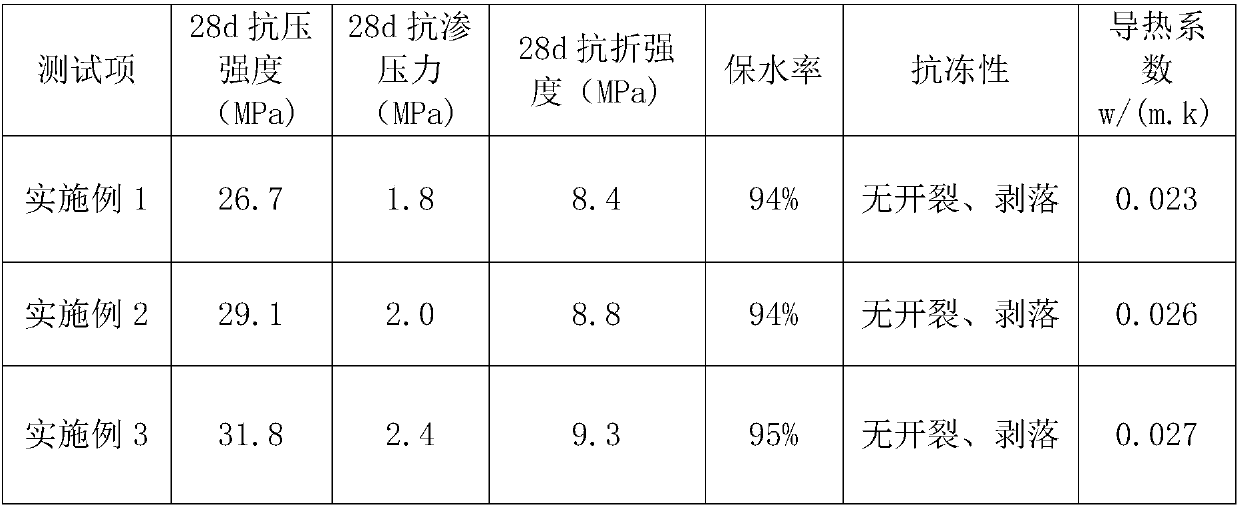

Examples

Embodiment 1

[0018] (1) In terms of parts by mass, weigh 25 parts of cement, 54 parts of sand, 2 parts of dispersible latex powder, 0.5 parts of cellulose ether, 2 parts of waterproofing agent, 1.5 parts of glass fiber, and 15 parts of glass microspheres. The cement is 42.5 ordinary Portland cement, and the sand is natural sand with a fineness of 70-140 mesh. The cellulose ether is hydroxypropyl methylcellulose, and the waterproofing agent is a high-grade fatty acid waterproofing agent. The diameter of the glass fiber is 1-3 mm, and the particle size of the glass microsphere is 500-800 mesh.

[0019] (2) Stir and mix the above-mentioned raw materials in a blender evenly to obtain a powder component.

[0020] (3) Select 35%-50% acrylate emulsion as the liquid material component with a solid content of 35%, mix the powder component and the liquid material component acrylate emulsion in step 2 at a mass ratio of 1:0.8, and use Stir evenly with an electric mixer for 3 minutes, and then let i...

Embodiment 2

[0022] (1) In terms of parts by mass, weigh 30 parts of cement, 52 parts of sand, 1.5 parts of dispersible latex powder, 0.7 parts of cellulose ether, 1.5 parts of waterproofing agent, 1.3 parts of glass fiber, and 13 parts of glass microspheres. The cement is ordinary portland cement of model 42.5, and the sand is made of recycled fine aggregate with a fineness of 70-140 mesh. The cellulose ether is hydroxypropyl methylcellulose, and the waterproofing agent is a higher fatty acid waterproofing agent. The diameter of the glass fiber is 1-3 mm, and the particle size of the glass microsphere is 500-800 mesh.

[0023] (2) Stir and mix the above-mentioned raw materials in a blender evenly to obtain a powder component.

[0024] (3) Select the acrylate emulsion with a solid content of 35%-50% as the liquid component, mix the powder component and the liquid component acrylate emulsion at a mass ratio of 1:0.8, and stir with an electric stirrer Evenly, stir for 5 minutes, and then l...

Embodiment 3

[0026] (1) In terms of parts by mass, weigh 35 parts of cement, 49 parts of sand, 1 part of dispersible latex powder, 1 part of cellulose ether, 1 part of waterproofing agent, 2 parts of glass fiber, and 11 parts of glass microspheres. The cement is ordinary portland cement of model 42.5, and the sand is machine-made sand with a fineness of 70-140 mesh. The cellulose ether is hydroxypropyl methylcellulose, and the waterproofing agent is a high-grade fatty acid waterproofing agent. The diameter of the glass fiber is 1-3 mm, and the particle size of the glass microsphere is 500-800 mesh.

[0027] (2) Stir and mix the above-mentioned raw materials in a blender evenly to obtain a powder component.

[0028] (3) Select the acrylate emulsion with a solid content of 35%-50% as the liquid component, mix the powder component and the liquid component acrylate emulsion at a mass ratio of 1:0.8, and stir with an electric stirrer Evenly, stir for 4 minutes, and then let it stand for 2 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com