Fen-flavor liquor fermentation device

A technology of fragrance-flavored liquor and fermentation equipment, which is applied in the field of liquor processing, and can solve the problems of liquor taste deviation, difficulty in liquor taste, spicy taste, etc., and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

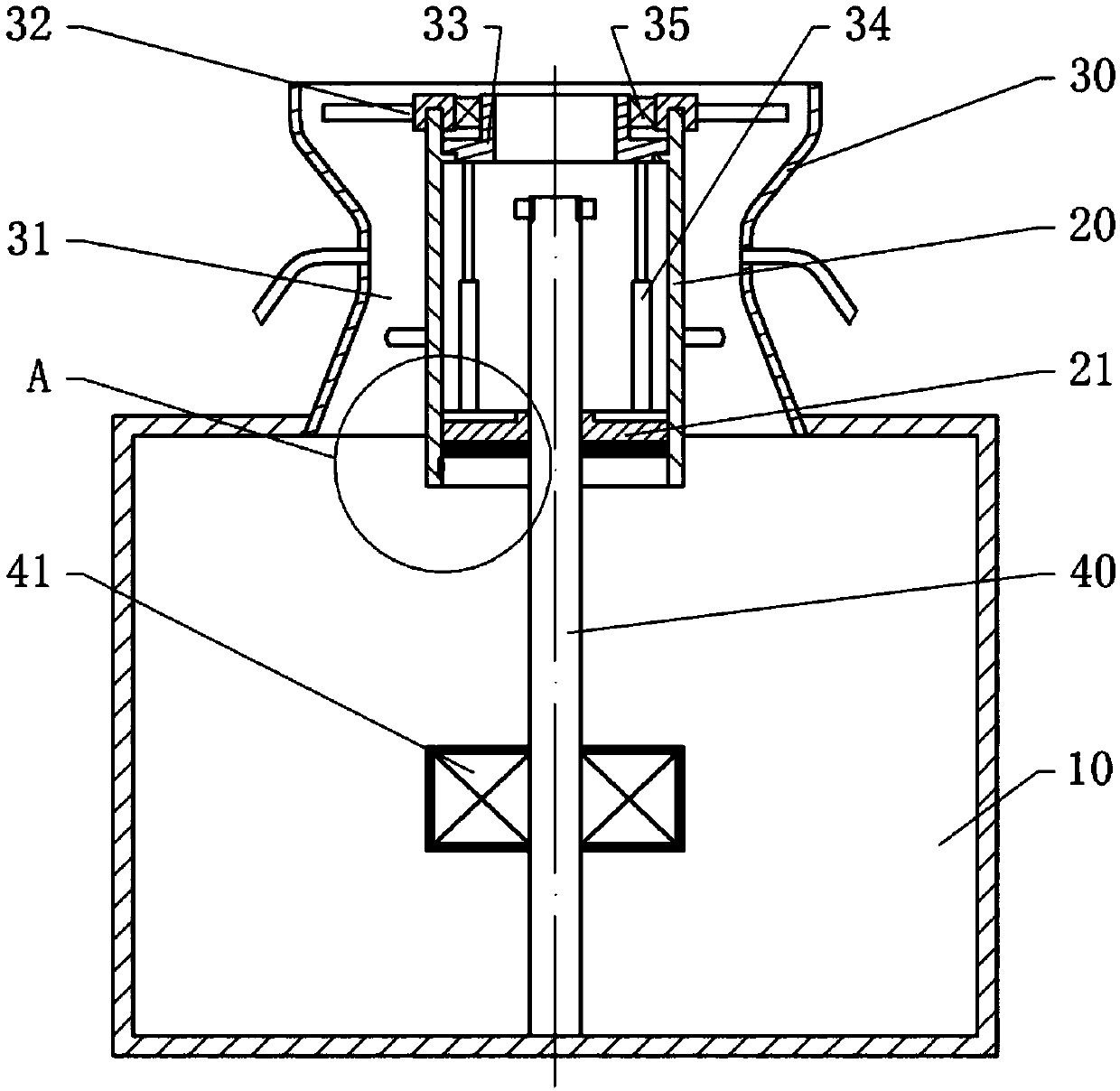

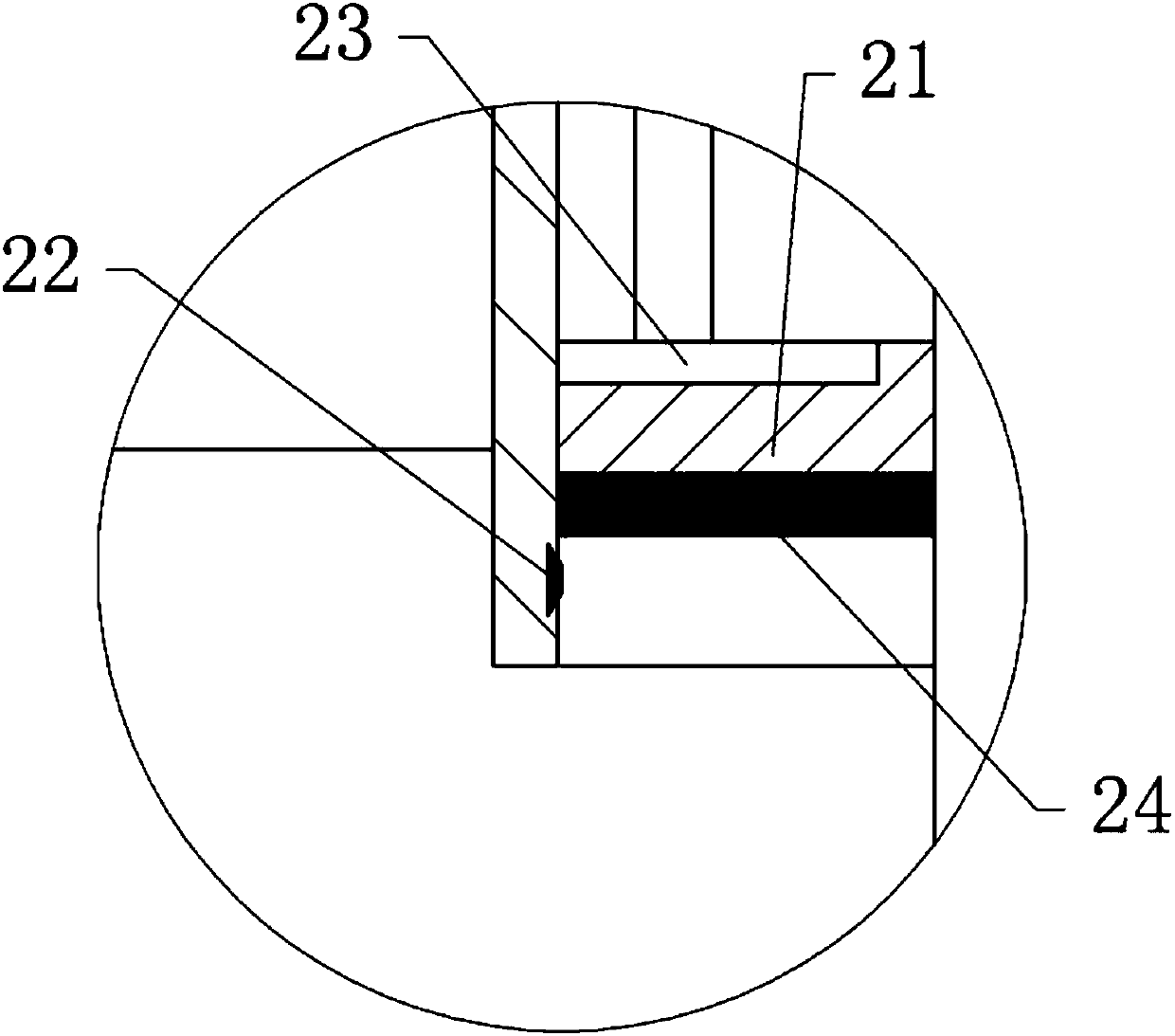

[0033] like figure 1 , figure 2As shown, the Fen-flavor liquor fermentation device of this embodiment includes a fermenter 10, and a feeding cylinder 20 communicating with the fermenter 10 is fixed on the top of the fermenter 10. The middle part of the feeding barrel 20 is provided with a screw rod 40 coaxial with the feeding barrel 20 , the lower end of the screw rod 40 extends into the fermenter 10 , and the lower end of the screw rod 40 is fixed to the bottom of the fermenter 10 . The feeding cylinder 20 is provided with a feeding tray 21 threadedly matched with the screw rod 40, and the helix angle of the thread that the screw rod 40 and the feeding tray 21 cooperate with each other is 58°, so that the thread does not have self-locking performance, that is, the feeding tray 21 It can slide downward under the action of its own gravity, and due to the threaded cooperation with the screw rod 40, the feeding tray 21 will rotate simultaneously during the downward sliding proc...

Embodiment 2

[0042] The difference between the second embodiment and the first embodiment is that in the second embodiment, the booster fan and the connecting ring are welded together, that is, when the feeding disc rotates, the booster fan rotates synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com