Extraction composition, extraction system and application of extraction composition

A composition and extraction technology, applied in the direction of improving process efficiency, etc., can solve the problems of insufficient extraction rate and back-extraction performance, strong corrosion of equipment, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 10

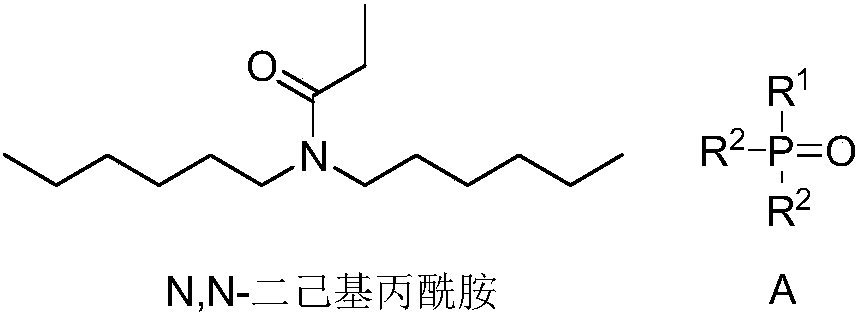

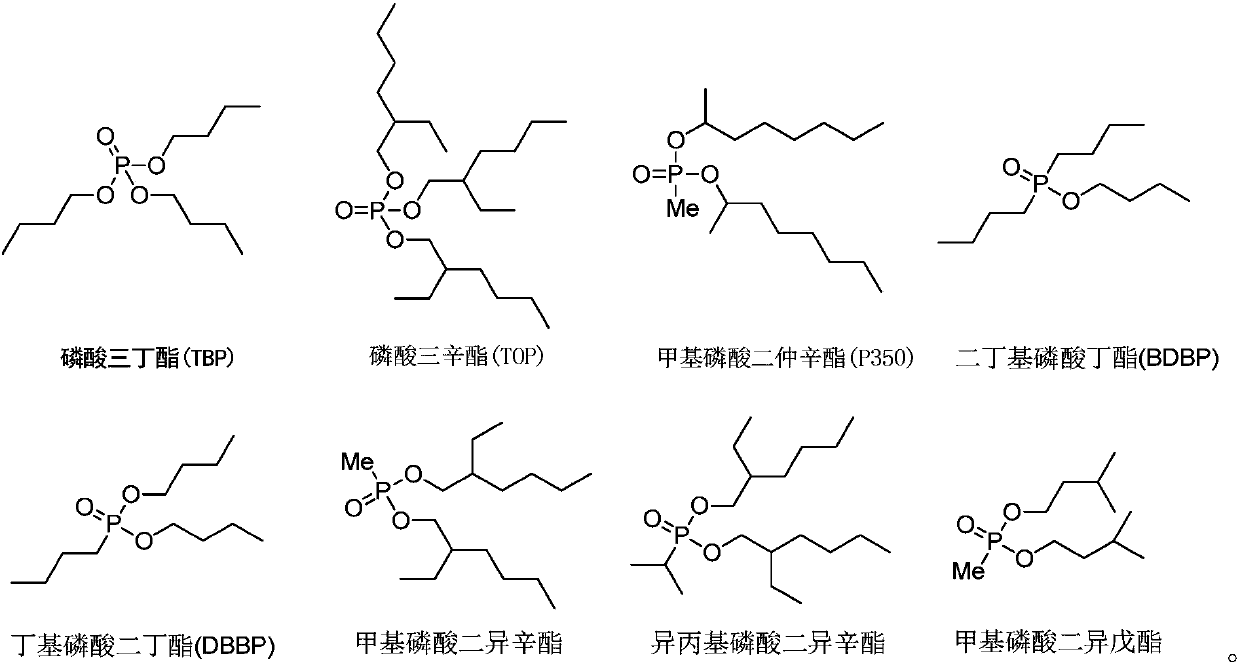

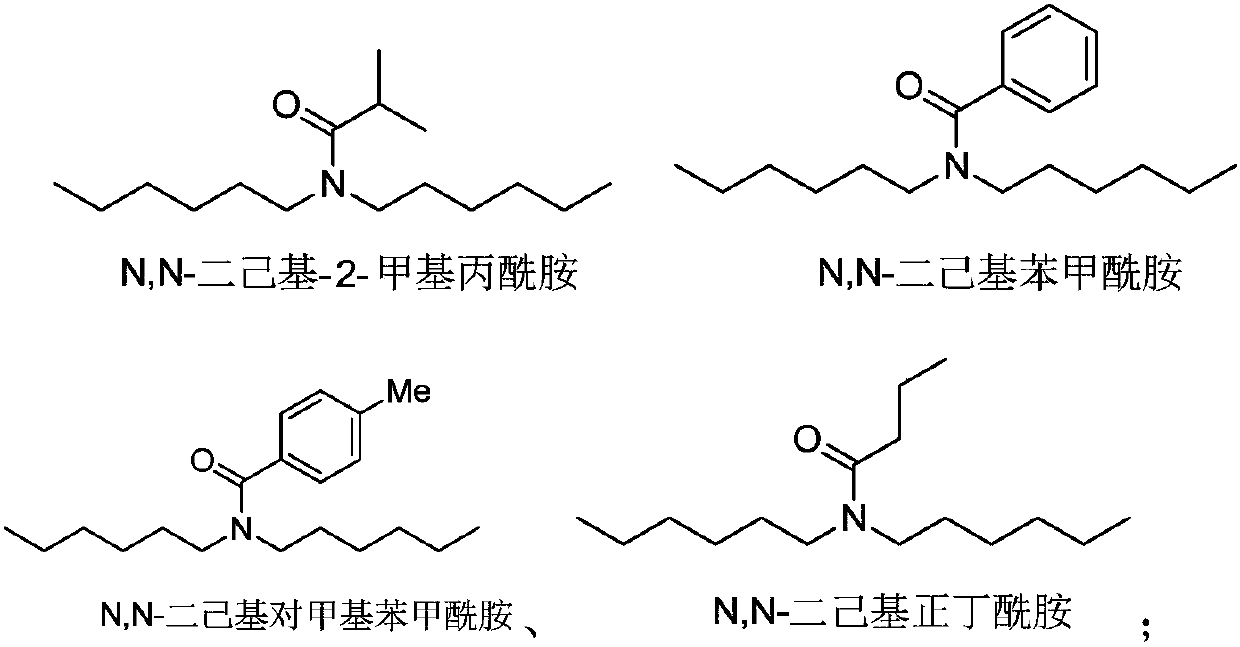

[0069] Organic phase: extractant + neutral phosphorus oxide compound + diluent

[0070] Aqueous phase: Lithium-containing brine

[0071] Phase (O:A) represents the volume ratio of the organic phase to the aqueous phase.

[0072] The specific operation is as follows:

[0073] A certain amount of FeCl 3 (Co-extraction agent) is added in lithium-containing brine, after shaking to make it dissolve, add organic phase, shake balance (oscillation time 5 minutes-30 minutes), leave standstill layering (obtain the organic phase containing lithium ion after equilibrium and water Mutually). Determination of Li in the equilibrium aqueous phase and organic phase, respectively + 、Na + 、K + and Mg 2+ Concentration, from which to calculate the extraction rate of Li, Li + , Mg 2+ 、Na + and K + The distribution ratio of Li / Mg, Li / Na, and Li / K separation coefficients.

Embodiment 11

[0075] Organic phase: extractant + neutral phosphorus oxide + diluent;

[0076] Water phase: Lithium-containing brine;

[0077] Compared (O:A): refers to the volume ratio of organic phase and aqueous phase;

[0078] The specific operation is as follows:

[0079] A certain amount of FeCl 3 (Co-extraction agent) was added in the organic phase, then added to the water phase, oscillating to balance (the oscillating time was 30 minutes), and standing to separate layers to obtain a balanced water phase and an organic phase containing lithium ions. Determination of Li in the equilibrium aqueous phase and organic phase, respectively + 、Na + 、K + and Mg2+ Concentration, from which to calculate the extraction rate of Li, Li + , Mg 2+ 、Na + and K + The distribution ratio of Li / Mg, Li / Na, and Li / K separation coefficients.

[0080] The experimental operation of Comparative Examples 1-4 is the same as that of Example 11.

[0081] The lithium-containing brine parameters of Example...

Embodiment 12

[0093] Embodiment 12 Stripping

[0094]

[0095] A certain amount of FeCl 3 (Co-extraction agent) add 60 parts (volume) lithium-containing brine (FeCl 3 Each component and content sees in embodiment 1,5,10 and comparative example 4) in consumption and lithium-containing brine, after shaking and making it dissolve, add in 30 parts (volume) embodiment 1,5,10 and comparative example 4 The organic phase was shaken for 10 minutes for extraction to obtain an organic phase loaded with lithium ions. Mix 30 parts (volume) of the organic phase loaded with lithium ions with 1 part (volume) of 6mol / L hydrochloric acid aqueous solution, shake at 25°C for 10 minutes, carry out back extraction, stand and separate the layers, and measure the Li in the two phases of back extraction equilibrium. + concentration. The specific parameters are shown in Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com