Sampling device and testing method for sulfur trioxide in flue gas

A technology of sulfur trioxide and sampling devices, which is applied in the direction of sampling devices, measuring devices, and the preparation of test samples, can solve the problems of undetectable concentrations and low measured values, and achieve simple and efficient testing processes, improved accuracy, and The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The concentration of sulfur trioxide in the flue gas was tested at the outlet of a denitrification device in a power plant.

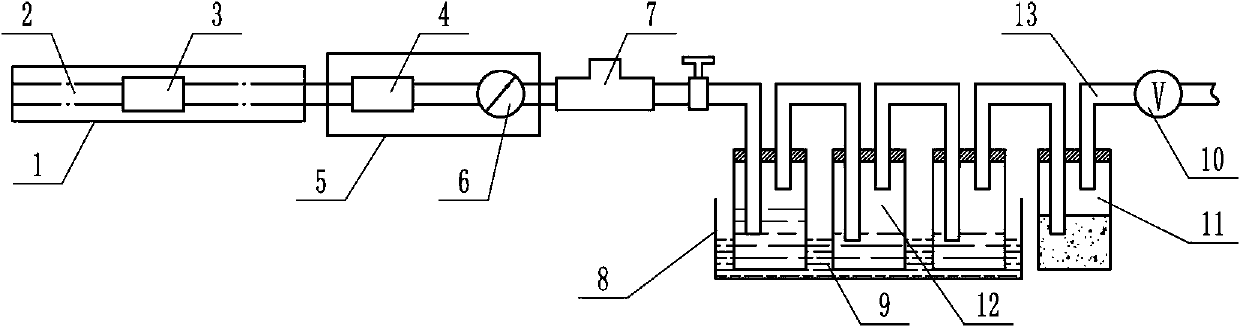

[0046] according to figure 1 As shown, connect the sulfur trioxide sampling device. After the sampling device is connected, check the airtightness of the entire device.

[0047] Heat the electric heating sampling gun, secondary filter and high-temperature air pump to 210°C, then pour ice water into the ice bath container; pour 100ml, 50ml and 50ml of 80% isopropanol into the third-level absorption bottle to absorb Add 2-3 drops of thorium reagent and 0.1ml of barium perchlorate standard solution dropwise into the third-level absorption bottle, place a desiccant in the drying bottle, and place the third-level absorption bottles in an ice-water bath. The concentration of the thorium reagent solution is 0.2g / L, and the concentration of the barium perchlorate standard solution is 0.001mol / L. The color of the liquid in the first two absorption bott...

Embodiment 2

[0053] The concentration of sulfur trioxide in the flue gas was tested at the outlet of a desulfurization device in a power plant.

[0054] according to figure 1 As shown, connect the sulfur trioxide sampling device. After the sampling device is connected, check the airtightness of the entire device.

[0055] Heat the electric heating sampling gun, secondary filter and high-temperature air pump to 220°C, then pour ice water into the ice bath container; pour 100ml, 50ml and 50ml of 80% isopropanol into the third-level absorption bottle to absorb Add 2-3 drops of thorium reagent and 0.2ml of barium perchlorate standard solution dropwise into the third-level absorption bottle, place a desiccant in the drying bottle, and place the third-level absorption bottles in an ice-water bath. The concentration of the thorium reagent solution is 0.3g / L, and the concentration of the barium perchlorate standard solution is 0.001mol / L. The color of the liquid in the first two absorption bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com