Phase change cooling-based optical fiber cooling device for fiber laser

A fiber laser, phase change cooling technology, applied in the direction of laser cooling device, laser parts, structure/shape of active medium, etc., can solve the problems of inability to export, ineffective storage of heat, low heat capacity, etc., to improve high power tolerance ability, reducing the risk of sudden temperature changes, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

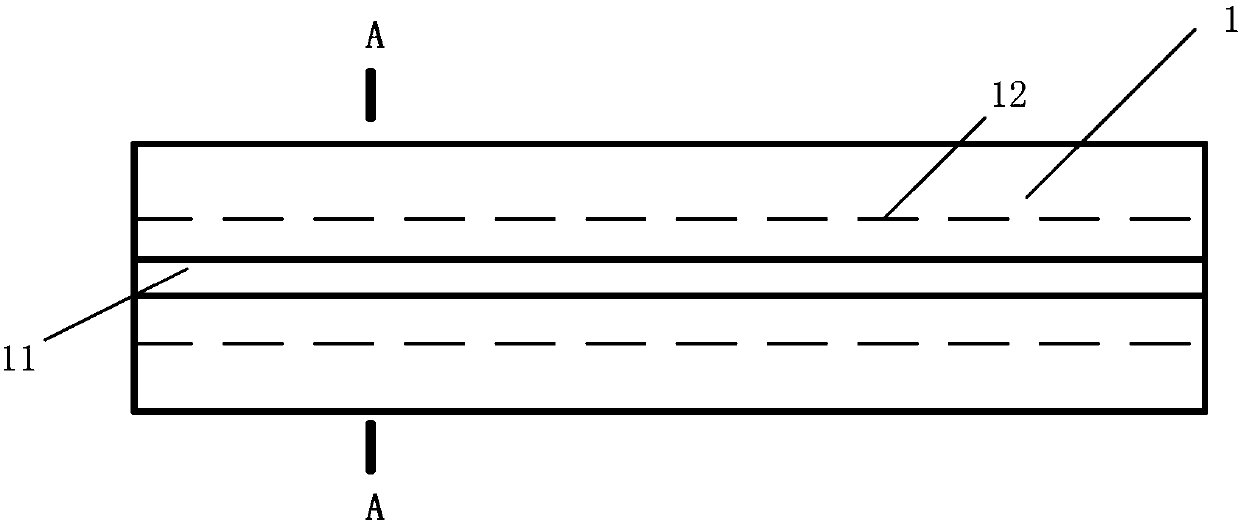

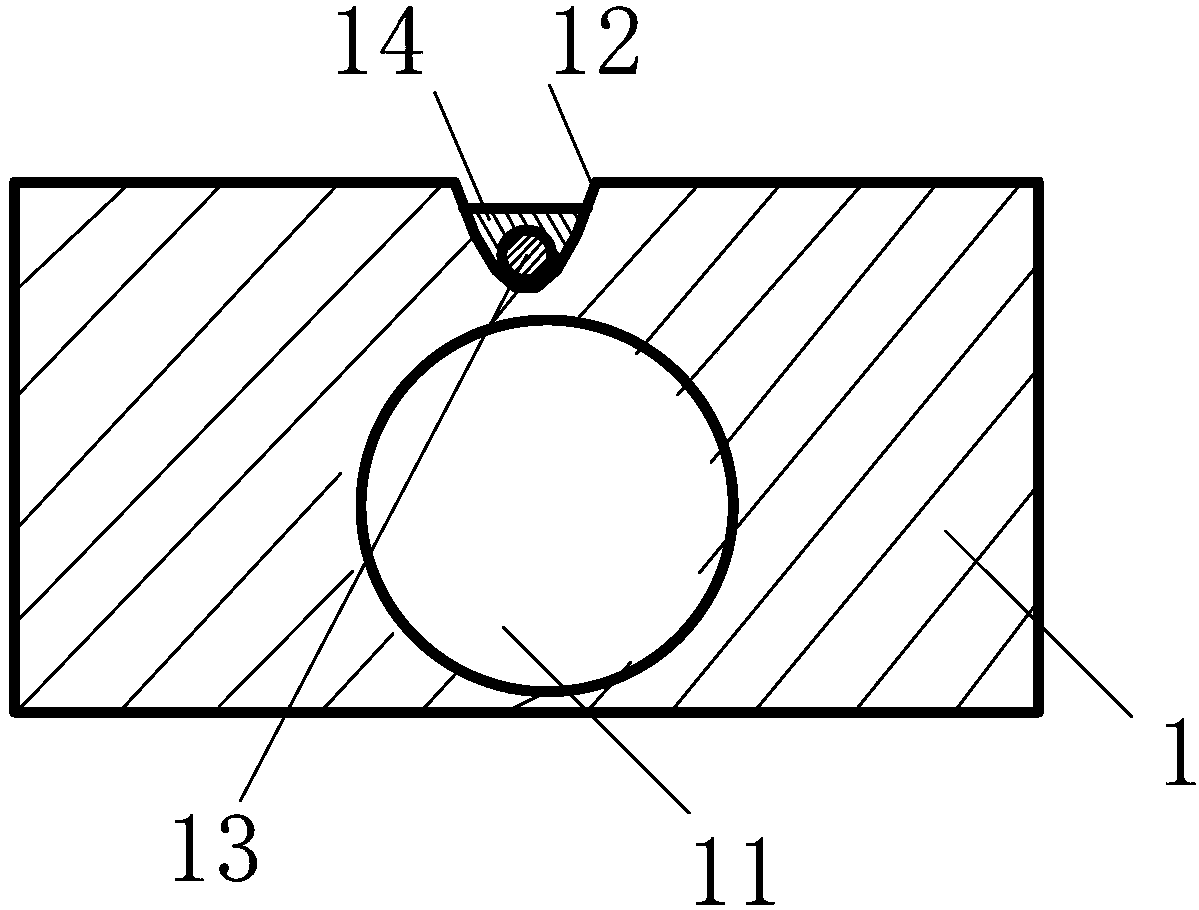

[0013] A fiber cooling device for a fiber laser based on phase change cooling, comprising a cooling heat sink 1, on which a fiber groove 12 is arranged, and a gain fiber 13 from which the coating layer has been removed is fixed in the fiber groove 12, wherein It is characterized in that the gain fiber 13 in the fiber groove 12 is filled with phase change material 14, and the phase change material 14 completely wraps the gain fiber 13 in the fiber groove 12 in the middle; there is a cooling water channel 11 in the cooling heat sink 1, cooling The water channel 11 is below the fiber groove 12 .

[0014] The phase change material 14 is a composite material composed of paraffin wax and graphite in any proportion, or an organic material with phase change properties of fully refined paraffin wax, myristyl alcohol, and stearic acid, or composed of stearic acid and metal powder in any proportion of composite materials.

[0015] The cross-section of the cooling water channel 11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com