Fermented milk with advantages of drinking experience improving and wall attachment reducing, and preparation method thereof

A technology of fermented milk and fermented material, applied in the field of fermented milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

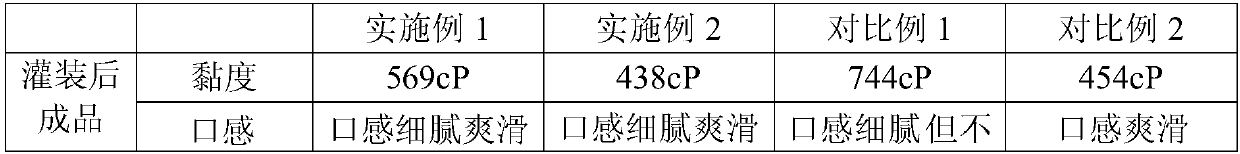

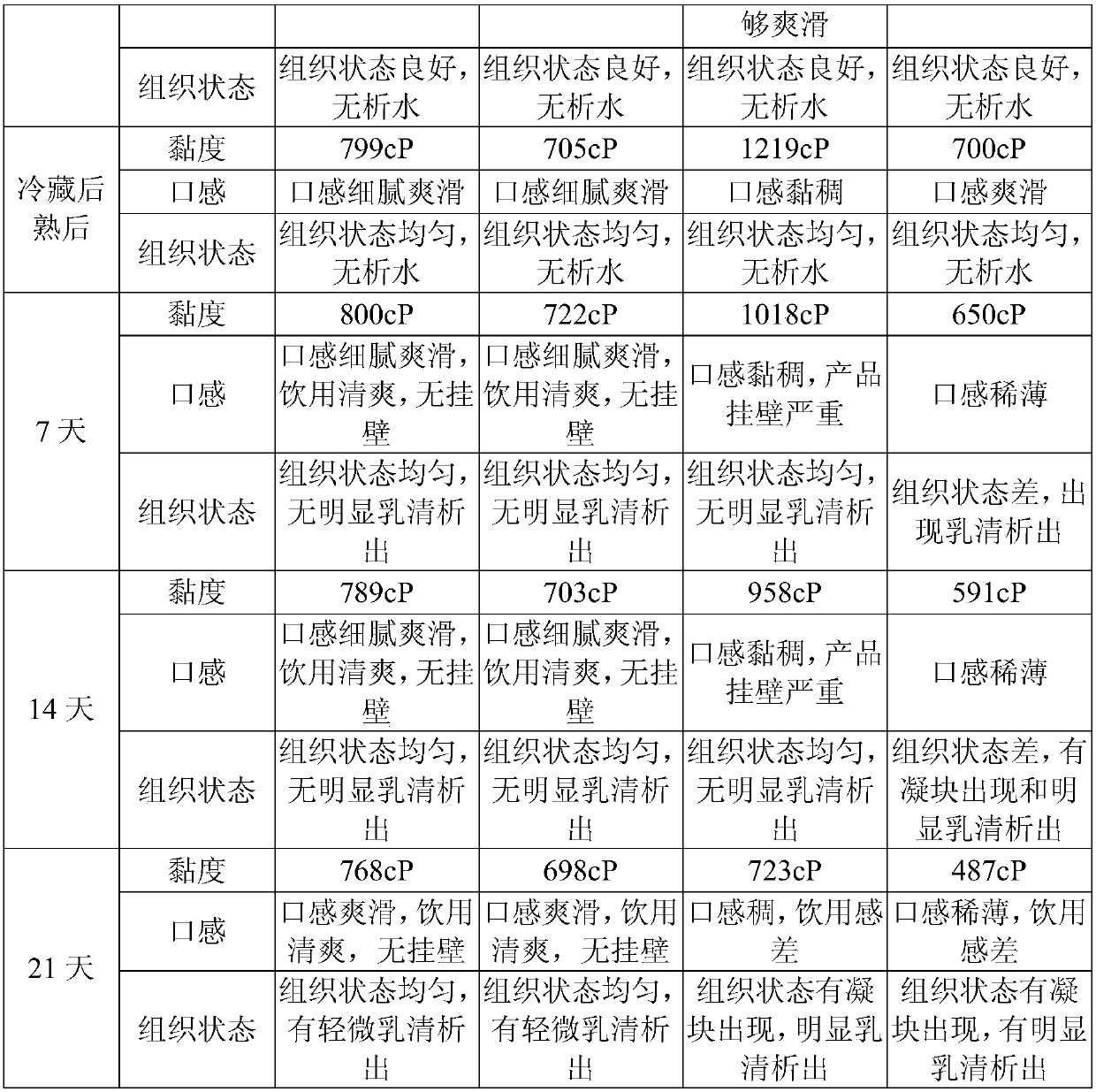

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing fermented milk that increases drinking physical examination and reduces wall hanging, and fermented milk prepared by the method.

[0041] The raw materials of this fermented milk are (in 1000g): fresh milk or reduced milk 936g, white granulated sugar 60g, starch 3g, agar 0.6g and leavening agent: Streptococcus thermophilus 1×10 6 cfu / g, Lactobacillus bulgaricus 1×10 6 cfu / g, Lactococcus lactis 1×10 6 cfu / g.

[0042] The preparation method of this fermented milk specifically comprises the following steps:

[0043] (1) After heating fresh milk or reduced milk to 45-55°C, add white granulated sugar, starch and agar, and stir for 25-35 minutes to mix them evenly to obtain a mixed material liquid;

[0044] (2) After degassing the mixed material liquid, homogenize it at 60°C and 20 MPa to obtain a homogeneous mixed material liquid;

[0045] (3) Sterilize the homogenized mixed material at 110° C. for 10 minutes, and cool down...

Embodiment 2

[0053] This embodiment provides a method for preparing fermented milk that increases drinking physical examination and reduces wall hanging, and fermented milk prepared by the method.

[0054] The raw materials of this fermented milk are (in 1000g): fresh milk or reduced milk 936g, white granulated sugar 60g, starch 3g, agar 0.6g and leavening agent: Streptococcus thermophilus 1×10 6 cfu / g, Lactobacillus bulgaricus 1×10 6 cfu / g, Lactococcus lactis 1×10 6 cfu / g.

[0055] The preparation method of this fermented milk specifically comprises the following steps:

[0056] (1) After heating fresh milk or reduced milk to 45-55°C, add white granulated sugar, starch and agar, and stir for 25-35 minutes to mix them evenly to obtain a mixed material liquid;

[0057] (2) After degassing the mixed material liquid, homogenize it at 60°C and 20 MPa to obtain a homogeneous mixed material liquid;

[0058] (3) Sterilize the homogenized mixed material at 110° C. for 10 minutes, and cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com