Castable material used for rapidly restoring city bridge expansion joint concrete and preparation method thereof

A technology of concrete and expansion joints, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve unsatisfactory problems, achieve improved compactness, high flexural and flexural strength, and good long-term strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The above-mentioned preparation method for the pouring material used for rapid repair of urban bridge expansion joint concrete comprises the following steps:

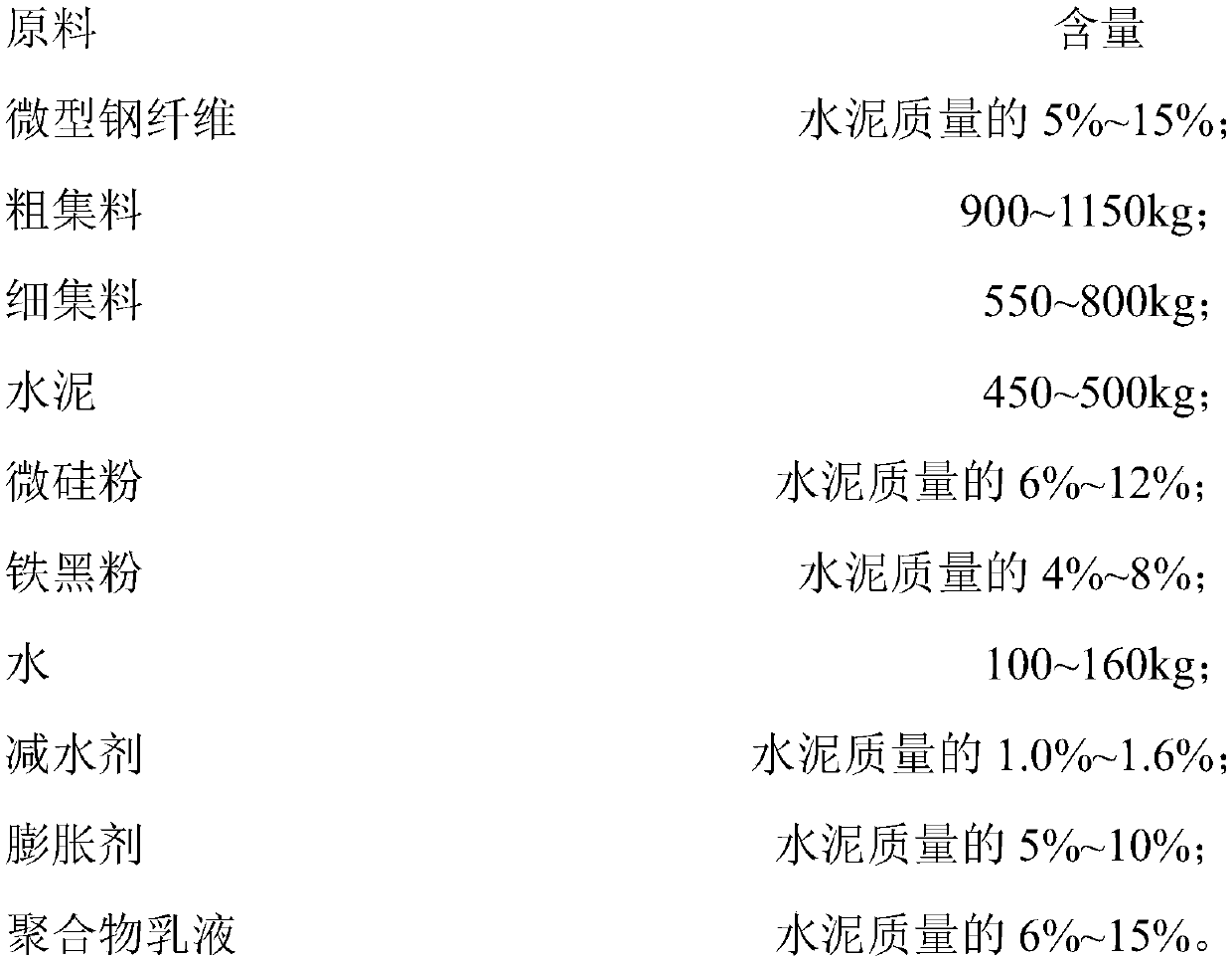

[0043] Prepare raw materials according to the following raw materials and content ratio:

[0044]

[0045]Dry mix the micro-steel fiber, coarse aggregate and fine aggregate for 1.5-2 minutes, then add cement, silica fume and black iron powder and stir for 1.5-2 minutes, then add water, water reducing agent, expansion agent and polymer emulsion, and wet mix 2 to 4 minutes until the concrete mixture has good fluidity;

[0046] The concrete mixture is molded, vibrated to shape, polished and plastered, and cured for 8-10 hours in an environment with a humidity of more than 90% and 20°C.

Embodiment 1

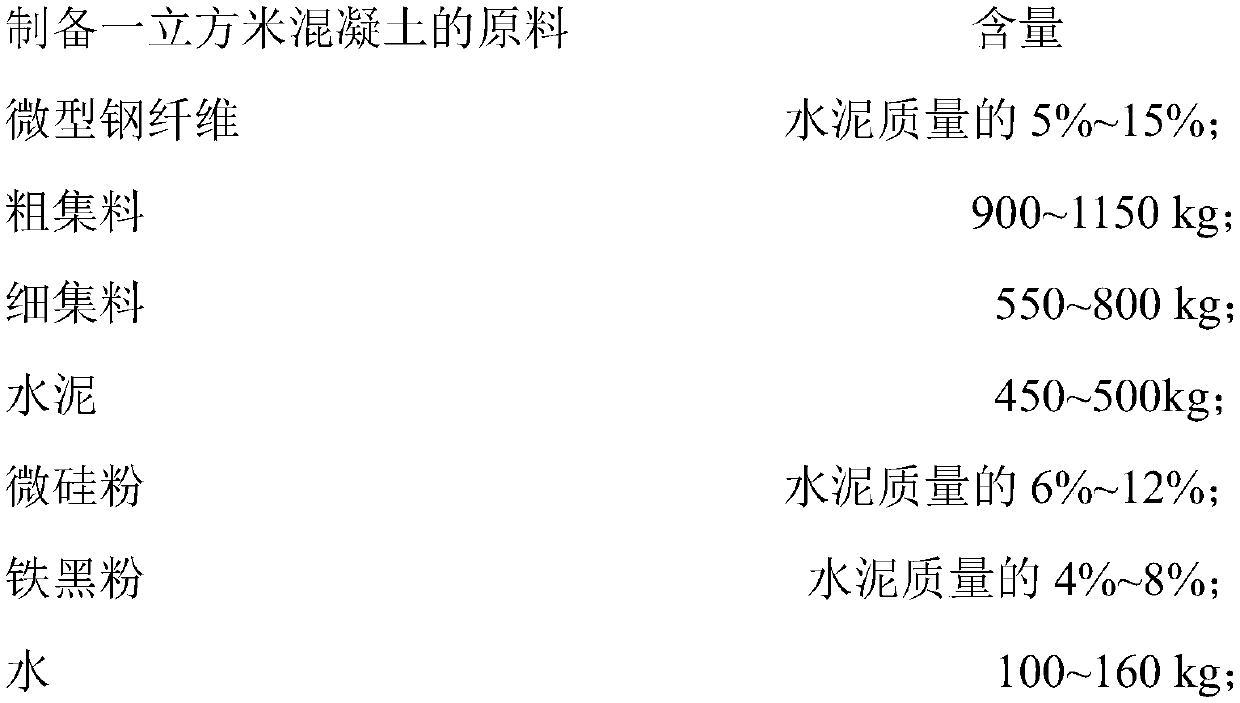

[0049] Embodiment 1 provides a kind of pouring material that is used for urban bridge expansion joint concrete rapid repair, and the raw material in every cubic meter of pouring material, content ratio are as follows:

[0050]

[0051] The length of the micro-steel fiber is 5-20mm, the diameter is 0.2-0.5mm, and the tensile strength is not less than 400MPa.

[0052] The particle size of the coarse aggregate is 5-16mm, the needle flake content ≤ 8%, the crushing value ≤ 18%, the mud content ≤ 1%, and other indicators meet the requirements for aggregates in JGJ52-2006.

[0053] The fine aggregate is medium-coarse sand, the mud content is ≤2%, the fineness modulus is ≥2.5, and other indicators meet the requirements for aggregates in JGJ52-2006.

[0054] The cement adopts early-strength sulphoaluminate cement, and the setting time is 30-60 minutes.

[0055] Silica fume SiO 2 Content ≥ 90%, moisture content ≤ 3%, density 2.2g / cm 3 , the specific surface area is 15000~25000m ...

Embodiment 2

[0065] Embodiment 2 provides a kind of pouring material that is used for urban bridge expansion joint concrete rapid repair, and the raw material in every cubic meter of pouring material, content ratio are as follows:

[0066]

[0067] The length of the micro-steel fiber is 5-20mm, the diameter is 0.2-0.5mm, and the tensile strength is not less than 400MPa.

[0068] The particle size of the coarse aggregate is 5-16mm, the needle flake content ≤ 8%, the crushing value ≤ 18%, the mud content ≤ 1%, and other indicators meet the requirements for aggregates in JGJ52-2006.

[0069] The fine aggregate is medium-coarse sand, the mud content is ≤2%, the fineness modulus is ≥2.5, and other indicators meet the requirements for aggregates in JGJ52-2006.

[0070] The cement adopts early-strength aluminate cement, and the setting time is 30-60 minutes.

[0071] Silica fume SiO 2 Content ≥ 90%, moisture content ≤ 3%, density 2.2g / cm 3 , the specific surface area is 15000~25000m 2 / kg....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com