Transparent guar gum and preparation method thereof

A technology of guar gum and guar gum sheet, which is applied in the field of transparent guar gum and its preparation, can solve the problems of cumbersome process, high cost, harsh raw material requirements, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of transparent guar gum, comprises the following steps:

[0028] (1) guar gum sheet is joined in lye, carries out alkalization reaction, obtains guar gum alkalization;

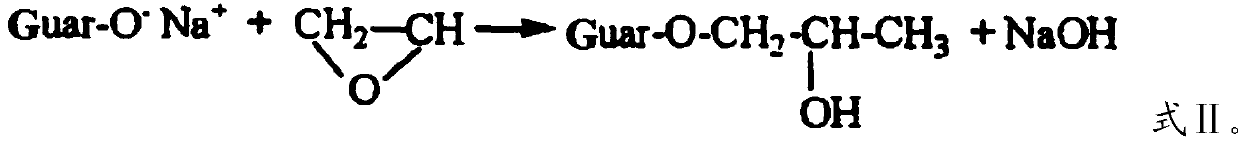

[0029] (2) the guar gum alkalization that described step (1) obtains is mixed with hydroxyalkyl etherification agent, carries out the first grafting reaction, obtains alkylation guar gum;

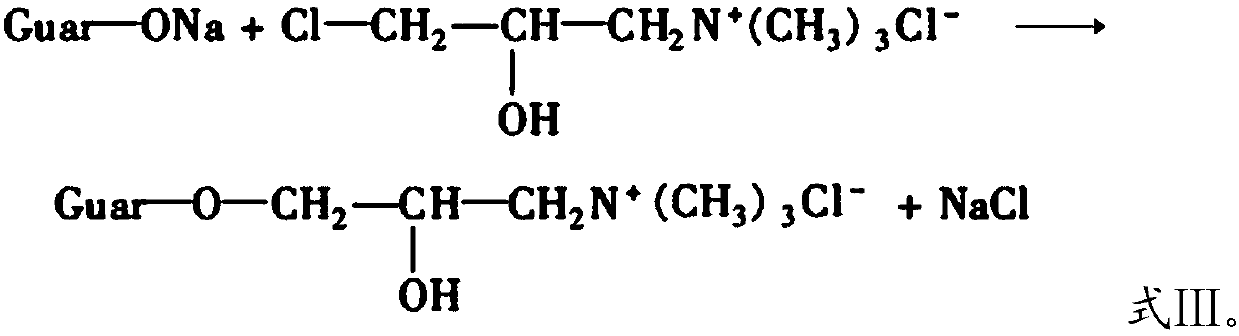

[0030] (3) mixing the alkylated guar gum obtained in the step (2) with the cationic etherifying agent, and carrying out the second grafting reaction to obtain the cationized guar gum;

[0031] (4) Mix the cationized guar gum that described step (3) obtains with oxidant, carry out oxidation reaction, obtain transparent guar gum.

[0032] In the invention, the guar gum flakes are added into the lye to carry out the alkalization reaction to obtain the guar gum alkalized product. The present invention has no special requirements on the source of the guar gum, and the ...

Embodiment 1

[0063] Take by weighing 150 grams of guar film and add in the reaction kettle. Weigh 20 grams of solid sodium hydroxide and dissolve it in 100 grams of water to form a sodium hydroxide solution, add it to the reaction kettle, and alkalize it at room temperature for 30 minutes; then add 150 g of propylene oxide dropwise, and control the dropping rate at 15-20mL / min within 10 minutes, combined with the external temperature supply, control the temperature during the dropping process at 50°C, then raise the temperature to 60°C, and react for 3 hours; then add 100 grams of 3-chloro-2-hydroxypropyl Trimethylammonium chloride, control the rate of addition within the range of 10-20mL / min, drop it within 10 minutes, continue to react at 60°C for 6 hours, and then add dropwise at 60°C with a mass concentration of 32.5 grams of 40% hypochlorous acid solution was added dropwise for 10 minutes, oxidized for 30 minutes at 60°C, and the prepared feed liquid was washed, filtered, crushed, dri...

Embodiment 2

[0066] Take by weighing 150 grams of guar film and add in the reaction kettle. Take by weighing 20 grams of solid sodium hydroxide and dissolve in 100 grams of water to form a sodium hydroxide solution, add it to the reactor, and alkalize it at normal temperature for 30 minutes, then add 80 g of propylene oxide dropwise to the reactor of the alkalization reaction, and control The dropping rate is in the range of 15-20mL / min, and the dropping is completed within 10 minutes. Combined with the external temperature supply, the temperature during the dropping process is controlled at 45°C; then the temperature is raised to 60°C, and the reaction is for 3 hours; then dropwise adding 100 gram of 3-chloro-2-hydroxypropyltrimethylammonium chloride, control the dropping rate in the range of 10-20mL / min, drop it within 10 minutes, combine the external temperature supply, control the temperature in the dropping process At 55°C, the dropping time is 10 minutes, and the reaction is continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com