Flame-retardant polyurethane foam preparation method

A technology of polyurethane foam and flame retardant polyol, which is applied in the field of polymer foam materials, can solve the problems of low flame retardant efficiency and large amount of flame retardant addition, and achieve high solid content, good flame retardant effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

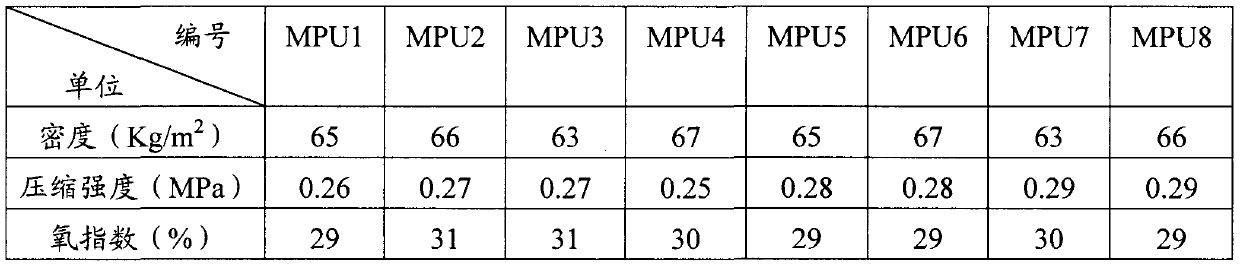

Examples

Embodiment 1

[0031] In the first step, add 170ml of ethylene glycol into the reaction kettle, adjust the pH of the solution to 10 with potassium hydroxide, and raise the temperature to 70°C;

[0032] In the second step, add 90g of paraformaldehyde, keep the temperature for 10 minutes, and keep the paraformaldehyde depolymerized and dissolved under alkaline conditions;

[0033] In the third step, 187g of benzomelamine was added and reacted for 100min at a pH value of 8.5 and a temperature of 85°C;

[0034] In the fourth step, the pH value of the solution is adjusted to 6 with formic acid, and the condensation and etherification reaction is carried out for 30 minutes;

[0035] Step 5: Adjust the pH value of the solution to 10 with potassium hydroxide, add 28.2 g of phenol, control the reaction temperature at 85° C. and react for 100 minutes to obtain a flame-retardant polyol, which is cooled for later use.

[0036] Take 100 parts of the flame retardant polyol, 1.6 parts of silicone foam sta...

Embodiment 2

[0038] In the first step, add 135ml of glycerol into the reaction kettle, adjust the pH of the solution to 11 with triethanolamine, and raise the temperature to 75°C;

[0039] In the second step, add 90g of paraformaldehyde, keep the temperature for 15 minutes, and keep the paraformaldehyde depolymerized and dissolved under alkaline conditions;

[0040] In the third step, 126 g of melamine was added and reacted for 100 min at a pH value of 9 and a temperature of 85° C.;

[0041] In the fourth step, the pH value of the solution is adjusted to 3 with formic acid, and the condensation and etherification reaction is carried out for 30 minutes;

[0042] Step 5: Adjust the pH value of the solution to 10 with triethanolamine, add 44 g of resorcinol, control the reaction temperature at 85° C. and react for 100 minutes to obtain a flame-retardant polyol, which is cooled for later use.

[0043] Get 100 parts of the flame retardant polyol and 1.8 parts of silicone foam stabilizer, 2 par...

Embodiment 3

[0045] In the first step, add 100ml polyethylene glycol 200 into the reaction kettle, adjust the pH of the solution to 10 with sodium hydroxide, and raise the temperature to 70°C;

[0046] In the second step, add 90g of paraformaldehyde, keep the temperature for 10 minutes, and keep the paraformaldehyde depolymerized and dissolved under alkaline conditions;

[0047]In the third step, add 60g of urea and react for 100min at pH 8.5 and temperature 85°C;

[0048] In the fourth step, the pH value of the solution is adjusted to 4 with formic acid, and the condensation and etherification reaction is carried out for 30 minutes;

[0049] The fifth step is to adjust the pH value of the solution to 10 with sodium hydroxide, add 44 g of hydroquinone, control the reaction temperature at 85° C. and react for 100 minutes to obtain a flame-retardant polyol, which is cooled for later use.

[0050] Take 100 parts of the flame retardant polyol, 1.6 parts of silicone foam stabilizer, 2 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com