Energy recovery type sludge drying and incineration system

A sludge drying and energy recovery technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of high operating costs, secondary pollution of heavy metals, and high energy consumption , to achieve the effect of high energy utilization rate, lower operating cost and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

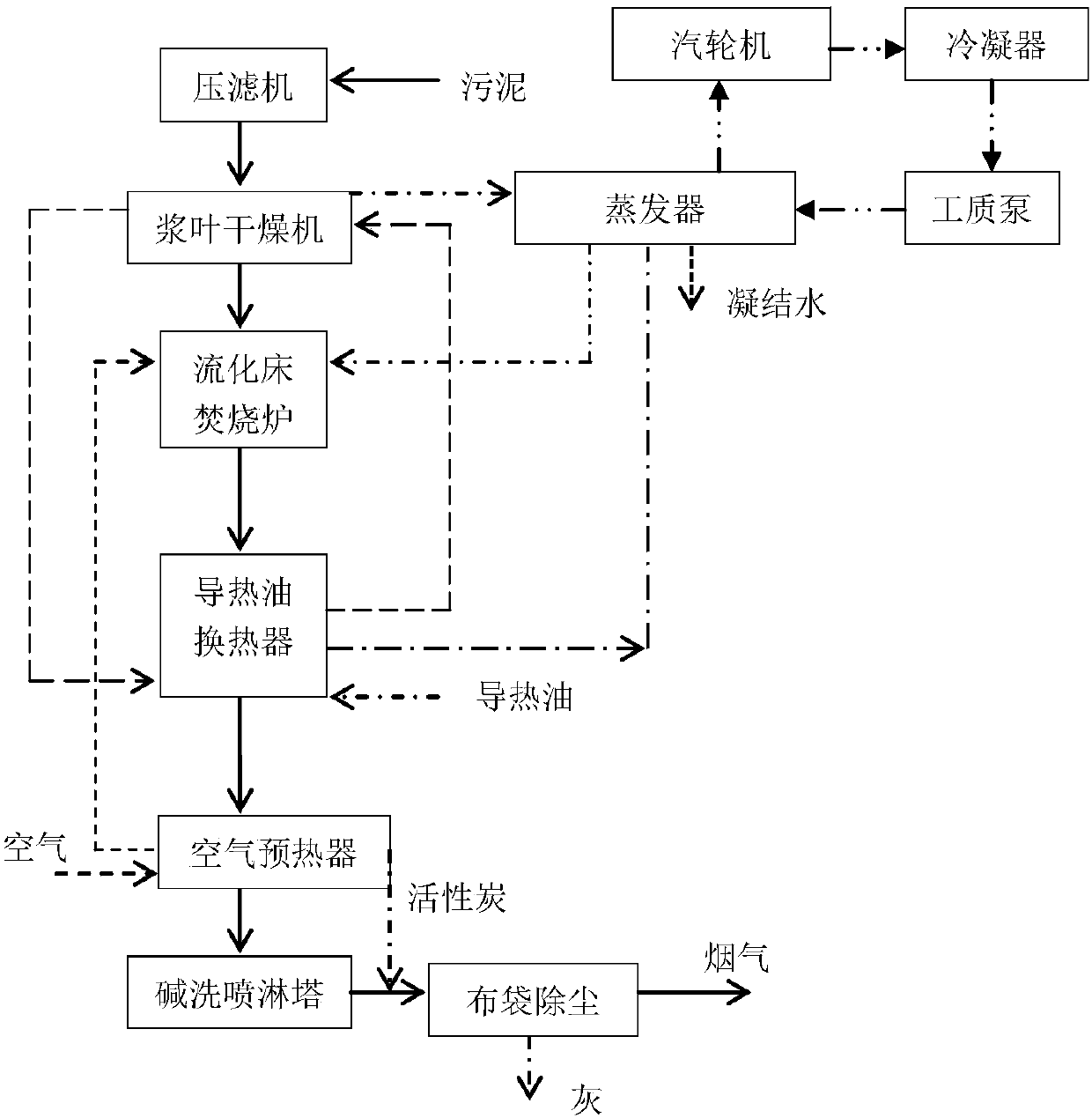

[0020] Such as figure 1 As shown, the energy recovery type sludge drying and incineration system of the present invention includes a filter press for sludge dehydration, a paddle dryer for drying, and an organic working medium evaporator for recovering steam generated during the drying process , steam turbine, condenser and working medium pump, fluidized bed incinerator for sludge incineration, heat transfer oil heat exchanger and air preheater for energy recovery, spray for absorbing pickling substances in flue gas towers, activated carbon injectors to absorb dioxins and heavy metals, baghouses to absorb dust.

[0021] The filter press is connected to the paddle dryer, the paddle dryer is connected to the evaporator, the evaporator is connected to the fluidized bed incinerator, the evaporator is connected to the steam turbine, the steam tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com