Low-temperature FDM (fused deposition modeling) 3D printing material and preparation and application thereof

A 3D printing, low-temperature technology, applied in the direction of additive processing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of high requirements for 3D printing equipment, complex implementation methods, low melt strength, etc., and achieve selectivity Wide, simple preparation method, good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

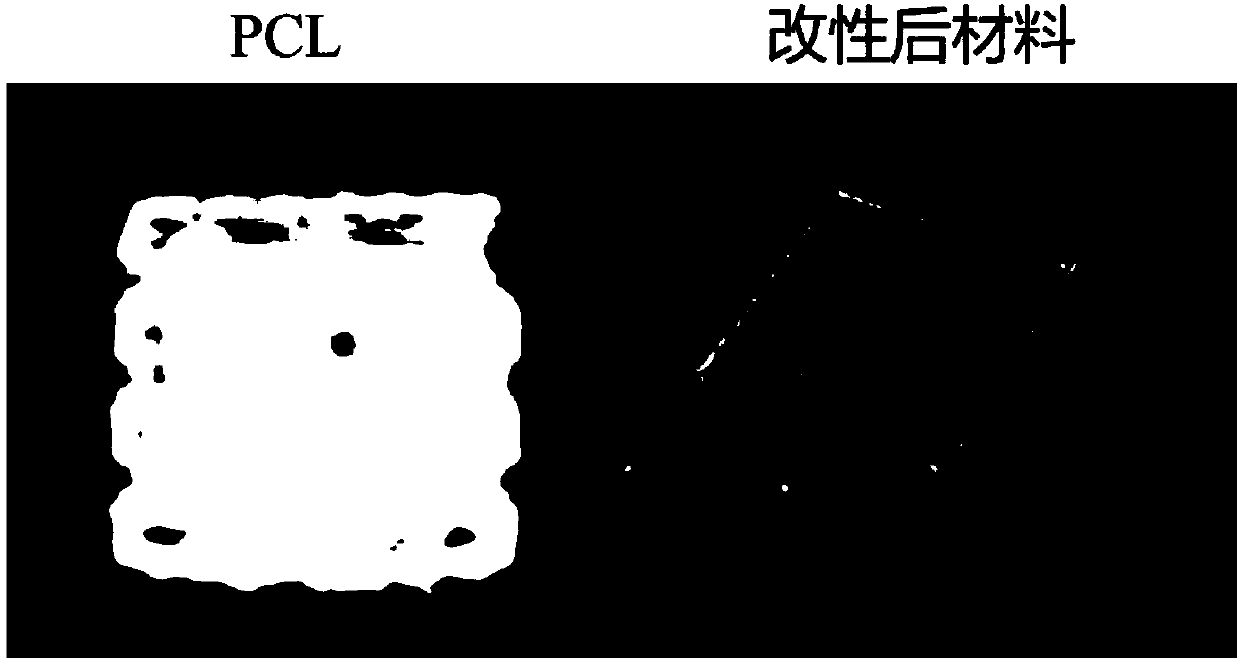

Embodiment 1

[0028] Weigh 88g of PCL masterbatch and place it in a 250mL beaker, then weigh and add 0.1g graphite, 3g EBS, 3g SiO 2 and 4.9 g magnesium stearate. Use a mixer to mix it well.

[0029] Put the mixture in a twin-screw extruder, and fully blend the PCL and the filler by means of melt blending. Set the temperature of zone 1, zone 2, zone 3 and zone 4 of the twin-screw extruder to 50, 75, 100 and 75°C, respectively. Set the screw speed at 20 rpm. After the blending is completed, the prepared materials are pulverized and granulated.

[0030] The prepared pellets are melted and extruded by a single-screw extruder, and pulled by a tractor to form a wire with uniform size. Set the temperature of the first zone and the second zone of the single-screw extruder to 80°C and 85°C respectively, the screw speed to 30rpm, and the wire size to 1.70-1.75mm.

[0031] When printing with an FDM 3D printer, set the 3D printer parameters as follows: nozzle temperature 85°C, base plate temperat...

Embodiment 2

[0033] Weigh 89g of PCL masterbatch and place it in a 250mL beaker, then weigh and add 1.1g graphite, 3g EBS, 3g SiO 2 and 3.9 g magnesium stearate. Use a mixer to mix it well.

[0034] Put the mixture in a twin-screw extruder, and fully blend the PCL and the filler by means of melt blending. The temperatures of the first zone, the second zone, the third zone and the fourth zone of the twin-screw extruder were respectively set to 60, 75, 90 and 75°C. Set the screw speed at 20 rpm. After the blending is completed, the prepared materials are pulverized and granulated.

[0035] The prepared pellets are melted and extruded by a single-screw extruder, and pulled by a tractor to form a wire with uniform size. Set the temperature of the first zone and the second zone of the single-screw extruder to 80°C and 85°C respectively, the screw speed to 30rpm, and the wire size to 1.70-1.75mm.

[0036] When printing with an FDM 3D printer, set the 3D printer parameters as follows: nozzle...

Embodiment 3

[0038] Weigh 90g of PCL masterbatch and place it in a 250mL beaker, then weigh and add 2g of graphite, 3g of EBS, and 2g of SiO 2 and 3 g of magnesium stearate. Use a mixer to mix it well.

[0039] Put the mixture in a twin-screw extruder, and fully blend the PCL and the filler by means of melt blending. Set the temperature of zone 1, zone 2, zone 3 and zone 4 of the twin-screw extruder to 50, 70, 90 and 75°C, respectively. Set the screw speed at 15 rpm. After the blending is completed, the prepared materials are pulverized and granulated.

[0040] The prepared pellets are melted and extruded by a single-screw extruder, and pulled by a tractor to form a wire with uniform size. Set the temperature of the first zone and the second zone of the single-screw extruder to 80 and 85° C., the screw speed to 40 rpm, and the wire size to 1.70-1.75 mm.

[0041] When printing with an FDM 3D printer, set the 3D printer parameters as follows: nozzle temperature 85°C, base plate temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com