Polyurethane coating with high solid content and high weather resistance and preparation method thereof

A polyurethane coating, high solid content technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor curing performance, and achieve the effects of reduced system viscosity, smooth paint film, and good pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

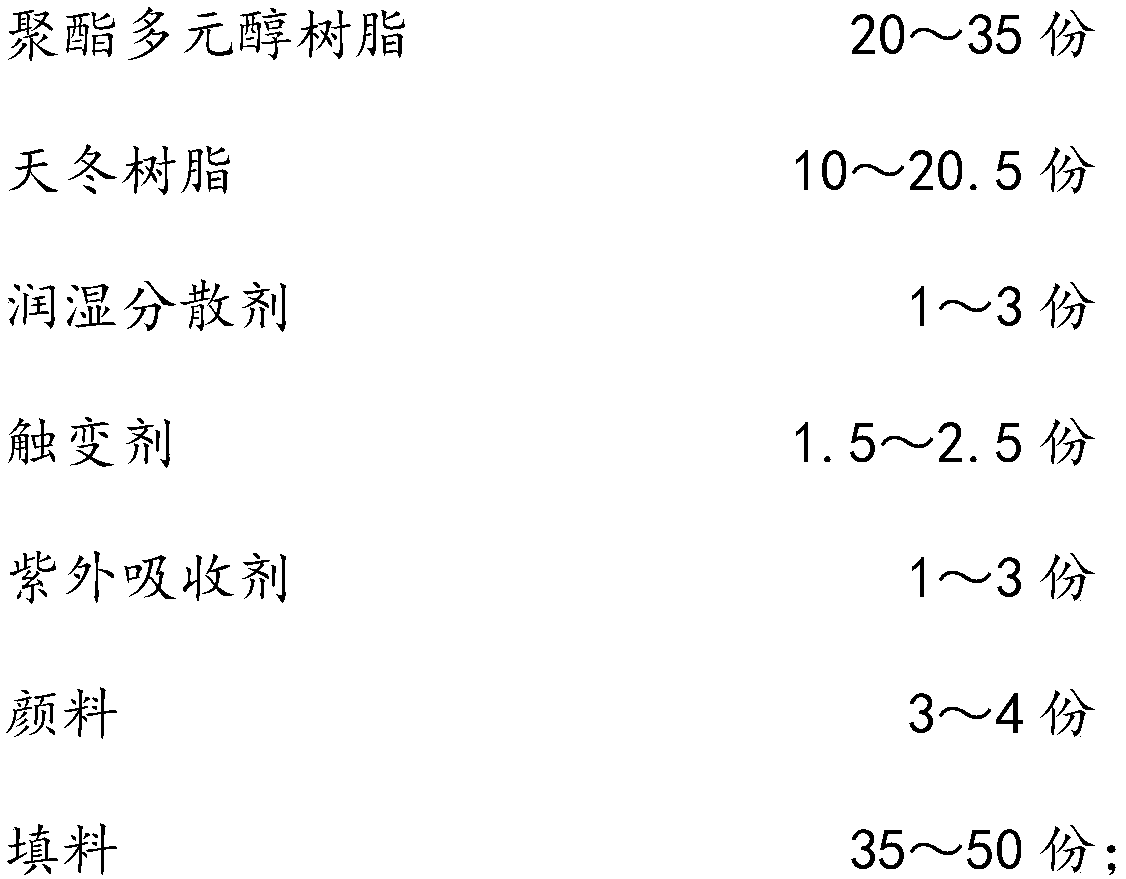

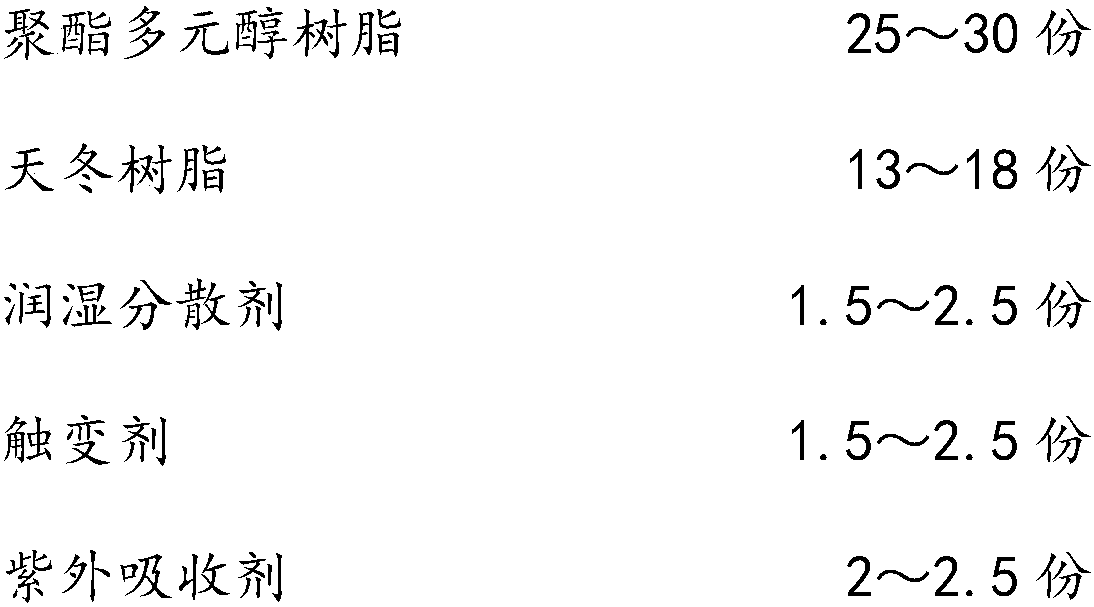

Method used

Image

Examples

Embodiment 1

[0044] Preparation of component A: Put 27 parts of polyester polyol and 18 parts of aspartic resin in a container and stir evenly, wherein the proportion of aspartic resin is 7.2 parts of aspartic resin with a viscosity of 155 mPa·s at 25°C, 25 parts of aspartic resin 10.8 parts of aspartame resin with a viscosity of 300mPa·s at ℃, then add 1.5 parts of wetting and dispersing agent and 2 parts of UV absorber, disperse and mix for 20-40min at a speed of 1300-1700r / min, add 4 parts of pigment, filler After dispersing and mixing 45 parts at a speed of 2800r / min to 3200r / min for 55 to 65 minutes, add 2.5 parts of thixotropic agent and disperse and mix at a speed of 1300 to 1700r / min for 20 to 40 minutes to make the coating fineness below 40μm and then filter A component can be obtained;

[0045] Preparation of component B: uniformly blend 36 parts of curing agent and 0.5 part of catalyst in a container and then filter to obtain component B. The curing agent is two polyisocyanates ...

Embodiment 2

[0047]Preparation of component A: Put 28 parts of polyester polyol and 14 parts of aspartic resin in a container and stir evenly, wherein the proportion of aspartic resin is 8.4 parts of aspartic resin with a viscosity of 155 mPa·s at 25°C, 25 parts of aspartic resin 5.6 parts of aspartame resin with a viscosity of 300mPa·s at ℃, then add 2 parts of wetting and dispersing agent and 2.5 parts of UV absorber, disperse and mix for 20-40min at a speed of 1300-1700r / min, add 3 parts of pigment, filler 49 parts and disperse and mix at a speed of 2800r / min to 3200r / min for 55min to 65min, add 1.5 parts of thixotropic agent and disperse and mix at a speed of 1300 to 1700r / min for 20 to 40min to make the coating fineness below 40μm and then filter A component can be obtained;

[0048] Preparation of component B: uniformly blend 33 parts of curing agent and 0.5 parts of catalyst in a container and then filter to obtain component B. The curing agent is two polyisocyanates with viscositie...

Embodiment 3

[0050] Preparation of component A: Put 30 parts of polyester polyol and 15 parts of aspartic resin in a container and stir evenly, wherein the proportion of aspartic resin is 10.5 parts of aspartic resin with a viscosity of 155 mPa·s at 4.5 parts of aspartame resin with a viscosity of 300mPa·s at ℃, then add 2.5 parts of wetting and dispersing agent and 1.5 parts of UV absorber, disperse and mix for 20-40min at a speed of 1300-1700r / min, add 3.5 parts of pigment, filler 45.5 parts and disperse and mix at a speed of 2800r / min to 3200r / min for 55min to 65min, add 2 parts of thixotropic agent and disperse and mix at a speed of 1300 to 1700r / min for 20 to 40min to make the coating fineness below 40μm and then filter A component can be obtained;

[0051] Preparation of component B: uniformly blend 29 parts of curing agent and 0.5 part of catalyst in a container and then filter to obtain component B. The curing agent is two polyisocyanates with viscosities of 500mPa·s and 2500mPa·s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com