Method for preparing flocculating agents by using compound strains

A technology of flocculant and compound bacteria, which is applied in the field of water treatment, can solve the problems of low flocculation activity, achieve the effects of promoting sedimentation, reducing the use of ethanol, and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

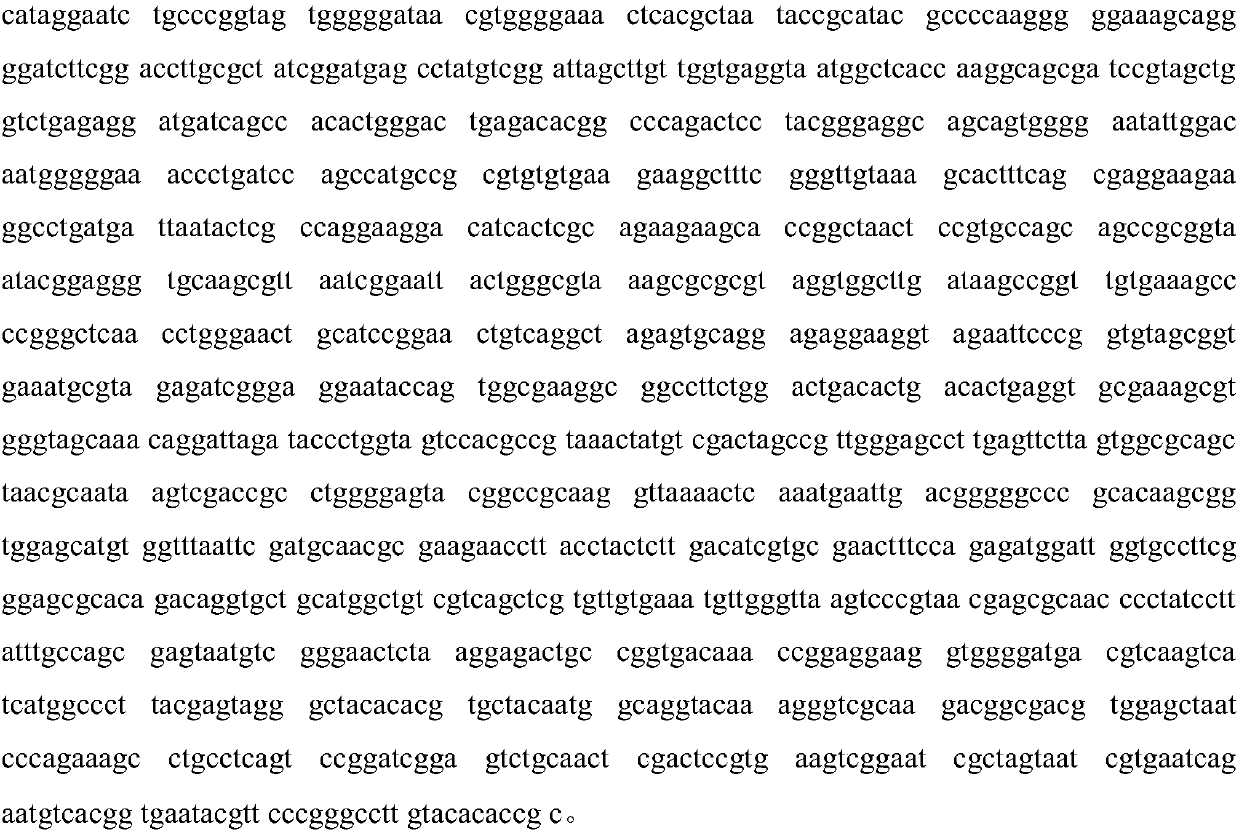

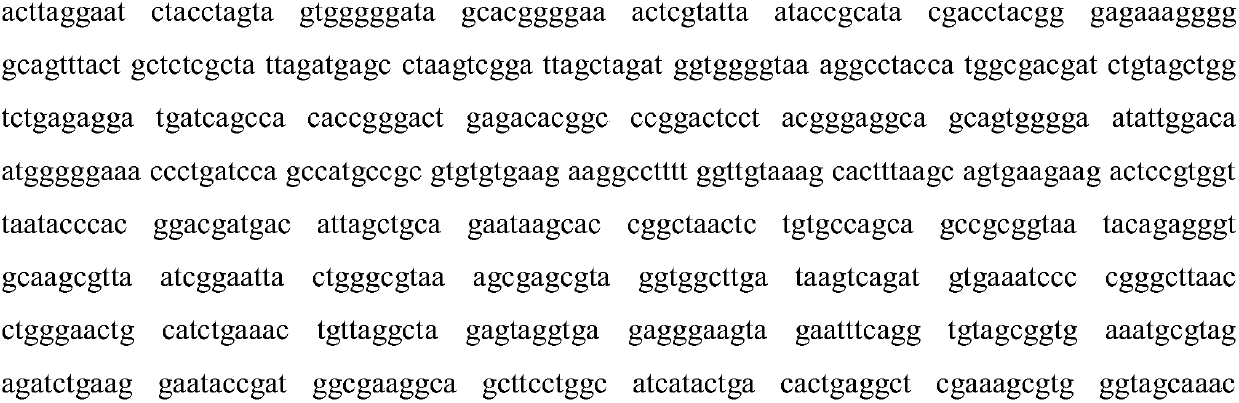

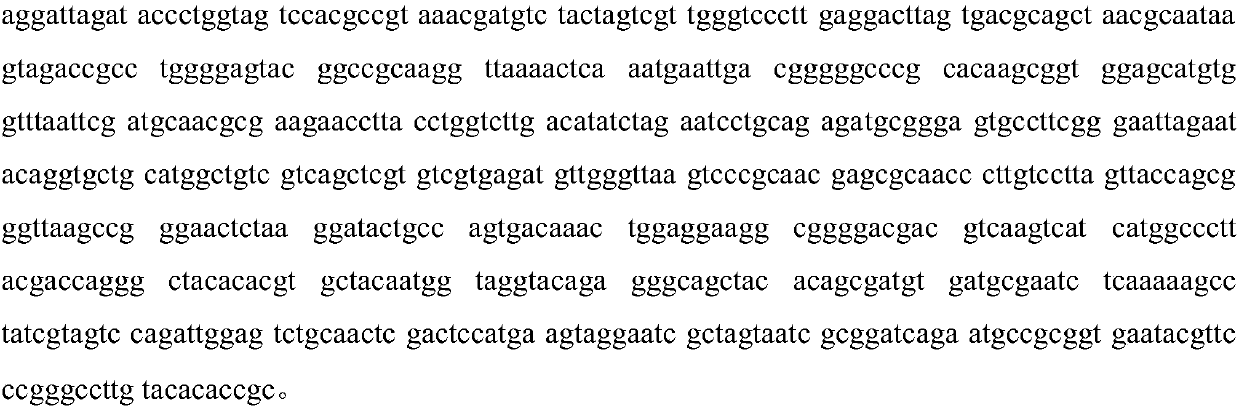

Image

Examples

Embodiment 1

[0041] A method for preparing a flocculant by using a compound bacterial agent, comprising the following steps:

[0042] (1) Inoculate the strains of Halomonas sp.GHF11 and Psychrobactersp.GHF2 on solid medium and culture them for 36 hours. The culture temperature of Halomonas sp.GHF11 is 25°C The culture temperature of Psychrobacter sp.GHF2 was 18°C, and sterile water was added to make GHF11 strain liquid and GHF2 strain liquid respectively, and the volume ratio of sterile water to solid medium was 1.0:1;

[0043] (2) According to the mixing volume ratio of GHF11 strain liquid and GHF2 strain liquid, the two strain liquids were mixed to obtain the mixed strain liquid, and then inoculated into the liquid culture medium, the inoculation concentration of the mixed strain liquid was 1.5mL mixed strain solution / 100mL liquid culture medium, fermented and cultured at 23°C for 3 days, and the shaking table rotated at 100r / min, to make a fermentation broth;

[0044] (3) Add flocculat...

Embodiment 2

[0053] A method for preparing a flocculant by using a compound bacterial agent, comprising the following steps:

[0054] (1) The strains of Halomonas sp.GHF11 and Psychrobacter sp.GHF2 were inoculated on solid medium for 42 hours, and the culture temperature of Halomonas sp.GHF11 was 28°C , the culture temperature of Psychrobacter sp.GHF2 was 20°C, and sterile water was added to make GHF11 strain liquid and GHF2 strain liquid respectively, and the volume ratio of sterile water to solid medium was 1.25:1;

[0055] (2) According to the mixed volume ratio of GHF11 strain liquid and GHF2 strain liquid as 1:1, mix the two strain liquids to obtain the mixed bacterial liquid, and then inoculate it into the liquid culture medium, the inoculation concentration of the mixed bacterial liquid is 2.0mL mixed bacteria solution / 100mL liquid culture medium, fermented and cultured at 25°C for 4 days, and the shaking table rotated at 140r / min, to make a fermentation broth;

[0056] (3) Add flo...

Embodiment 3

[0065] A method for preparing a flocculant by using a compound bacterial agent, comprising the following steps:

[0066] (1) Inoculate the strains of Halomonas sp.GHF11 and Psychrobactersp.GHF2 on solid medium and culture them for 48 hours. The culture temperature of Halomonas sp.GHF11 is 30°C , the culture temperature of Psychrobacter sp.GHF2 was 23°C, and sterile water was added to make GHF11 strain liquid and GHF2 strain liquid respectively, and the volume ratio of sterile water to solid medium was 1.5:1;

[0067] (2) According to the mixed volume ratio of GHF11 strain liquid and GHF2 strain liquid as 2:1, mix the two strain liquids to obtain the mixed bacterial liquid, and then inoculate it into the liquid culture medium, the inoculation concentration of the mixed bacterial liquid is 2.5mL mixed bacteria liquid / 100mL liquid culture medium, fermented and cultured at 27°C for 5 days, and the shaking table rotated at 160r / min, to make a fermentation broth;

[0068] (3) Add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com