Three-dimensional scanning laser radar based on MEMS micromirror

A technology of three-dimensional scanning and laser radar, which is applied in the field of laser detection, can solve problems such as restricting the development of multi-line laser radar, limited characteristic information of the object to be measured, and increased vertical volume, and achieves convenient installation and adjustment, reduced emission diodes, and power Effect of heat dissipation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

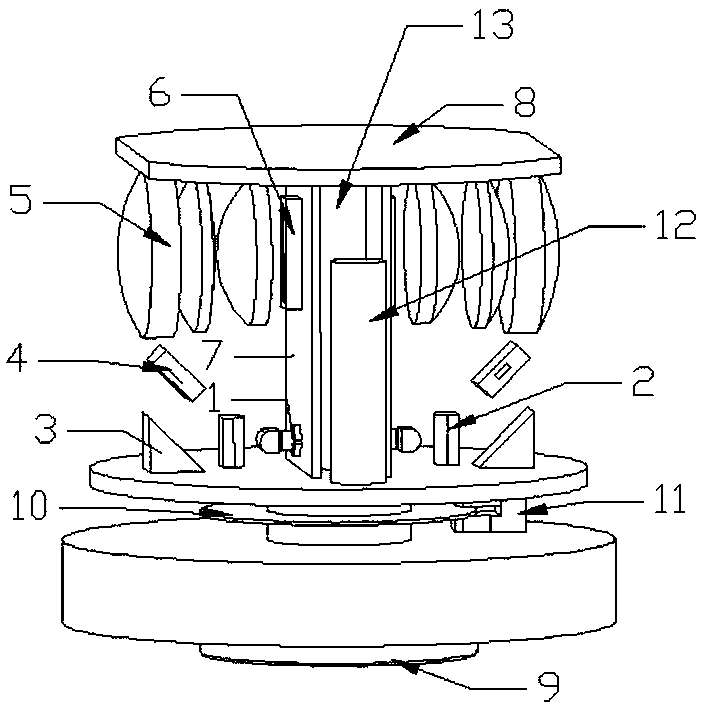

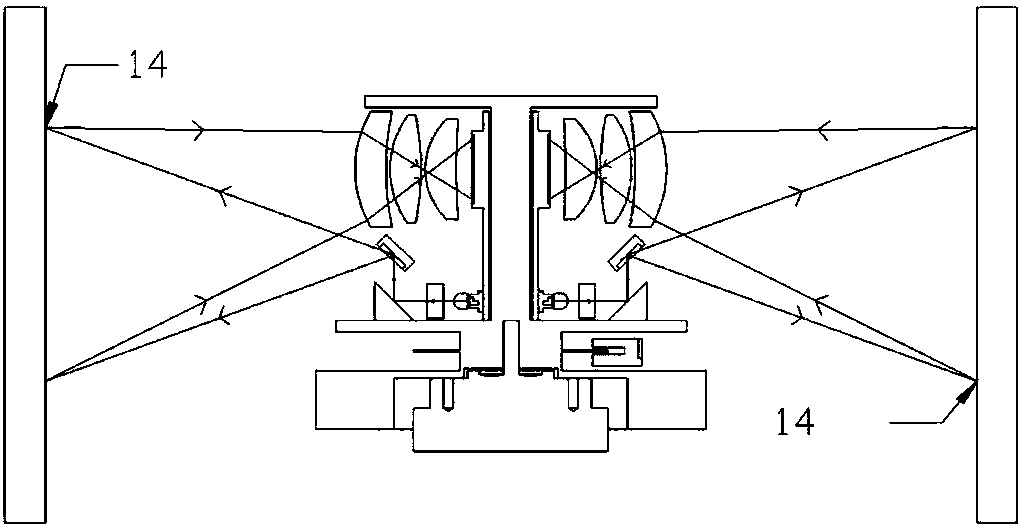

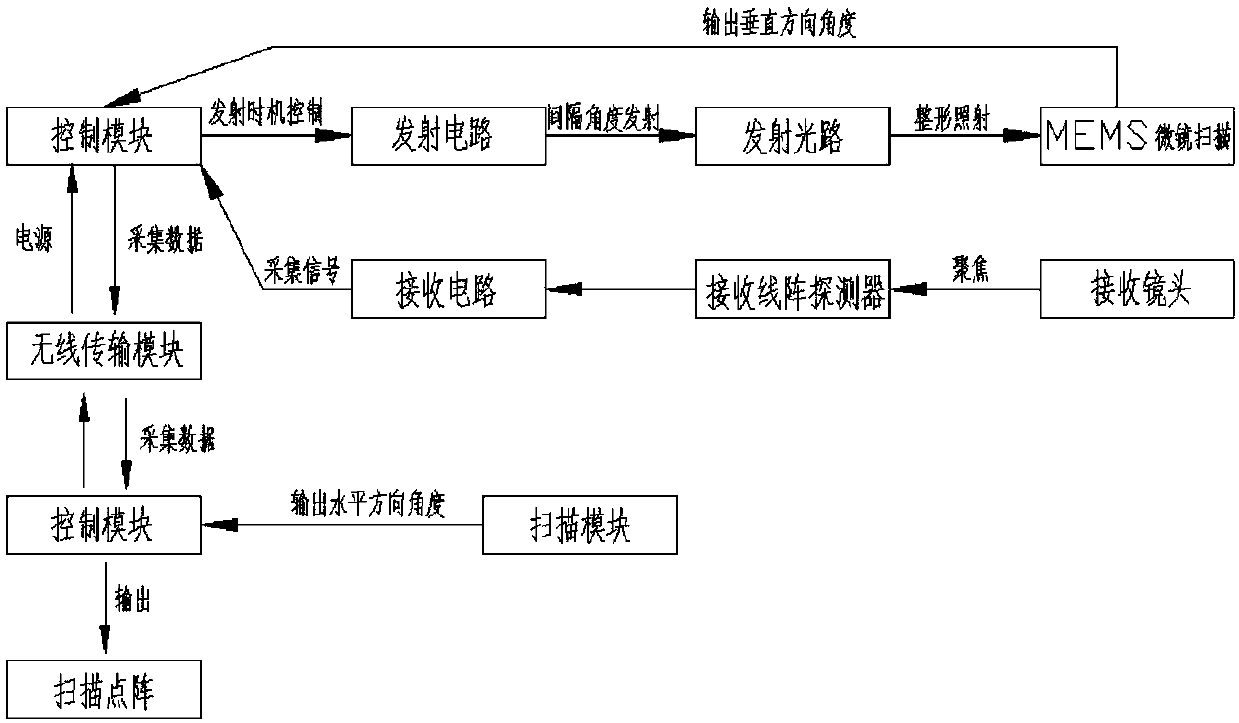

[0032] In order for those skilled in the art to better understand the technical solution of the present invention, a MEMS micromirror-based three-dimensional scanning laser radar provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0033] A three-dimensional scanning laser radar based on a MEMS micromirror, including: a transmitting module, which is used to scan and emit laser light in the vertical direction, and output the vertical direction emission angle; a receiving module, which is used to receive the echo signal reflected by the object to be measured; The module is connected with the transmitting module and the receiving module, and is used to provide high voltage for the transmitting module and the receiving module; the counterweight module is used for the counterweight of the entire rotating body to achieve dynamic balance; the scanning module rotates and scans in the horizontal direction, and outputs the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com