Method for microwave hydrothermal preparation of 1T@2H-MoS2

A microwave hydrothermal and deionized water technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, molybdenum sulfide, etc., can solve problems such as hidden safety hazards, difficult conditions to control, and complicated operations. Achieve the effects of easy popularization, simple operation and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

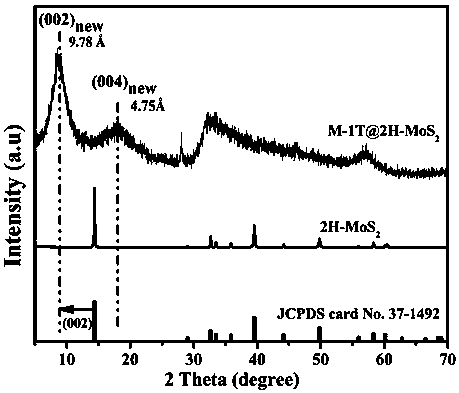

[0030] Dissolve 1mmol of ammonium heptamolybdate and 15mmol of thiourea in 35ml of distilled water, and continue magnetic stirring at room temperature for 30min to form a homogeneous solution. Transfer the solution to a polytetrafluoroethylene-lined microwave instrument, and set the microwave program to at 200°C for 10 min, and then cooled to room temperature after the end of the program. A microwave-one-step sample (denoted as M1) was collected by centrifugation. For the second time, the M1 sample was dissolved in 25 ml of alcohol and transferred to a Teflon-lined microwave instrument. At this time, the program was set at 220 °C for 4 min, and cooled to room temperature after the program ended. After centrifugation, the collected product was dissolved in ethanol and sonicated for 20 min and vacuum-dried at 60 °C to obtain 1T@2H-MoS 2 . (marked as M-1T@2H-MoS 2 ). Such as figure 1 Shown is the XRD pattern of the resulting product. Compared to 2H-MoS 2 , 1T@2H-MoS 2 New...

Embodiment 2

[0032] Dissolve 1mmol of ammonium heptamolybdate and 15mmol of thiourea in 35ml of distilled water, and continue magnetic stirring at room temperature for 30min to form a homogeneous solution. Transfer the solution to a polytetrafluoroethylene-lined microwave instrument, and set the microwave program to at 200°C for 10 min, and then cooled to room temperature after the end of the program. A microwave-one-step sample (denoted as M1) was collected by centrifugation. For the second time, the M1 sample was dissolved in 25 ml of alcohol and transferred to a Teflon-lined microwave instrument. At this time, the program was set at 220 °C for 6 min, and cooled to room temperature after the program was completed. After centrifugation, the collected product was dissolved in ethanol and sonicated for 20 min and vacuum-dried at 60 °C to obtain 1T@2H-MoS 2 . (marked as M-1T@2H-MoS 2 ). Such as image 3 Shown; is the TEM image of the obtained product, proving that the prepared MoS 2 ar...

Embodiment 3

[0034] Dissolve 1mmol of ammonium heptamolybdate and 15mmol of thiourea in 35ml of distilled water, and continue magnetic stirring at room temperature for 30min to form a homogeneous solution. Transfer the solution to a polytetrafluoroethylene-lined microwave instrument, and set the microwave program to at 200°C for 10 min, and then cooled to room temperature after the end of the program. A microwave-one-step sample (denoted as M1) was collected by centrifugation. For the second time, the M1 sample was dissolved in 25 ml of alcohol and transferred to a Teflon-lined microwave instrument. At this time, the program was set at 220 °C for 8 min, and cooled to room temperature after the program ended. After centrifugation, the collected product was dissolved in ethanol and sonicated for 20 min and vacuum-dried at 60 °C to obtain 1T@2H-MoS 2 . (marked as M-1T@2H-MoS 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com