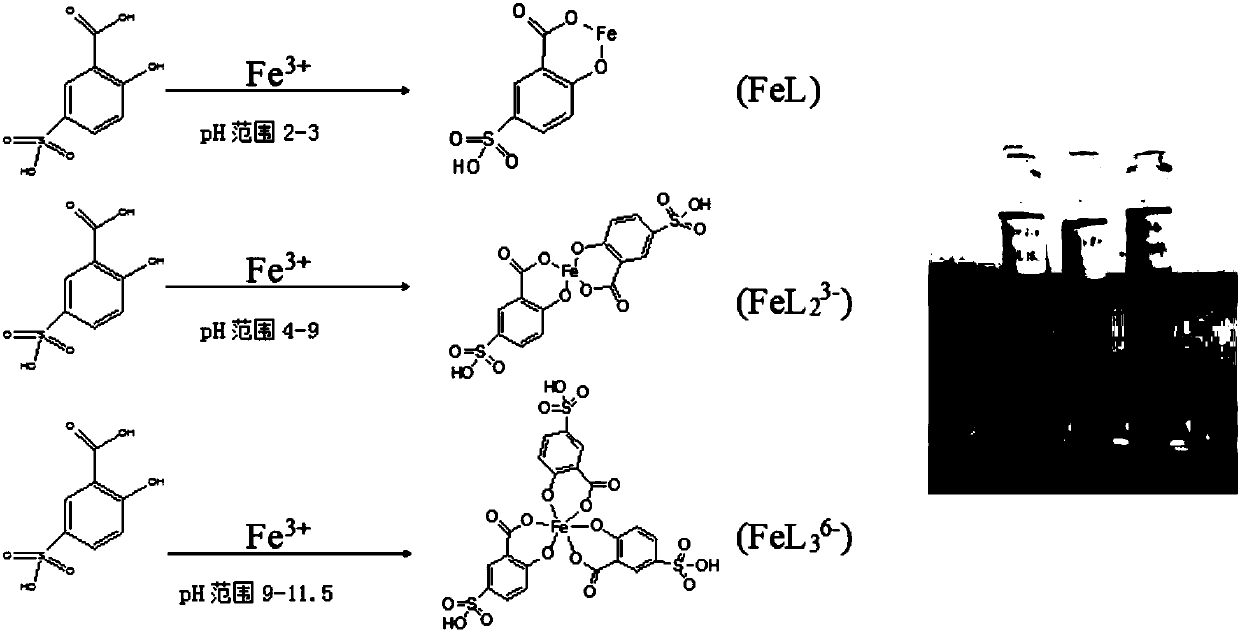

Method for coloring aluminum pigment by 5-sulfosalicylic acid dihydrate-iron ion complexes

A technology of sulfosalicylic acid and complexes, which is applied in the treatment of low-molecular-weight organic compounds in dyeing, pigment slurry, and inorganic pigments. It can solve the problems of unstable color aluminum pigments and achieve brilliant colors and good dispersibility. , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

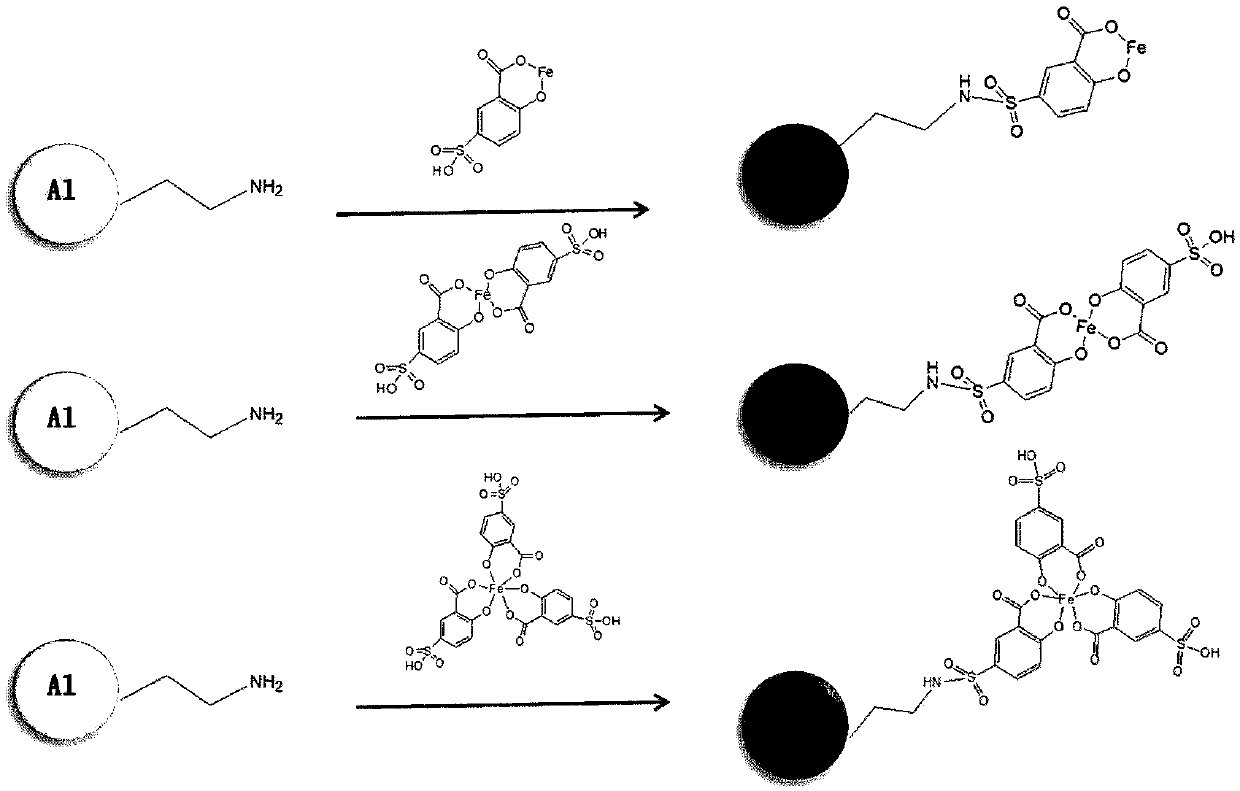

Method used

Image

Examples

Embodiment 1

[0043] In the present embodiment, the method of utilizing 5-sulfosalicylic acid iron ion complex to color the aluminum pigment is as follows:

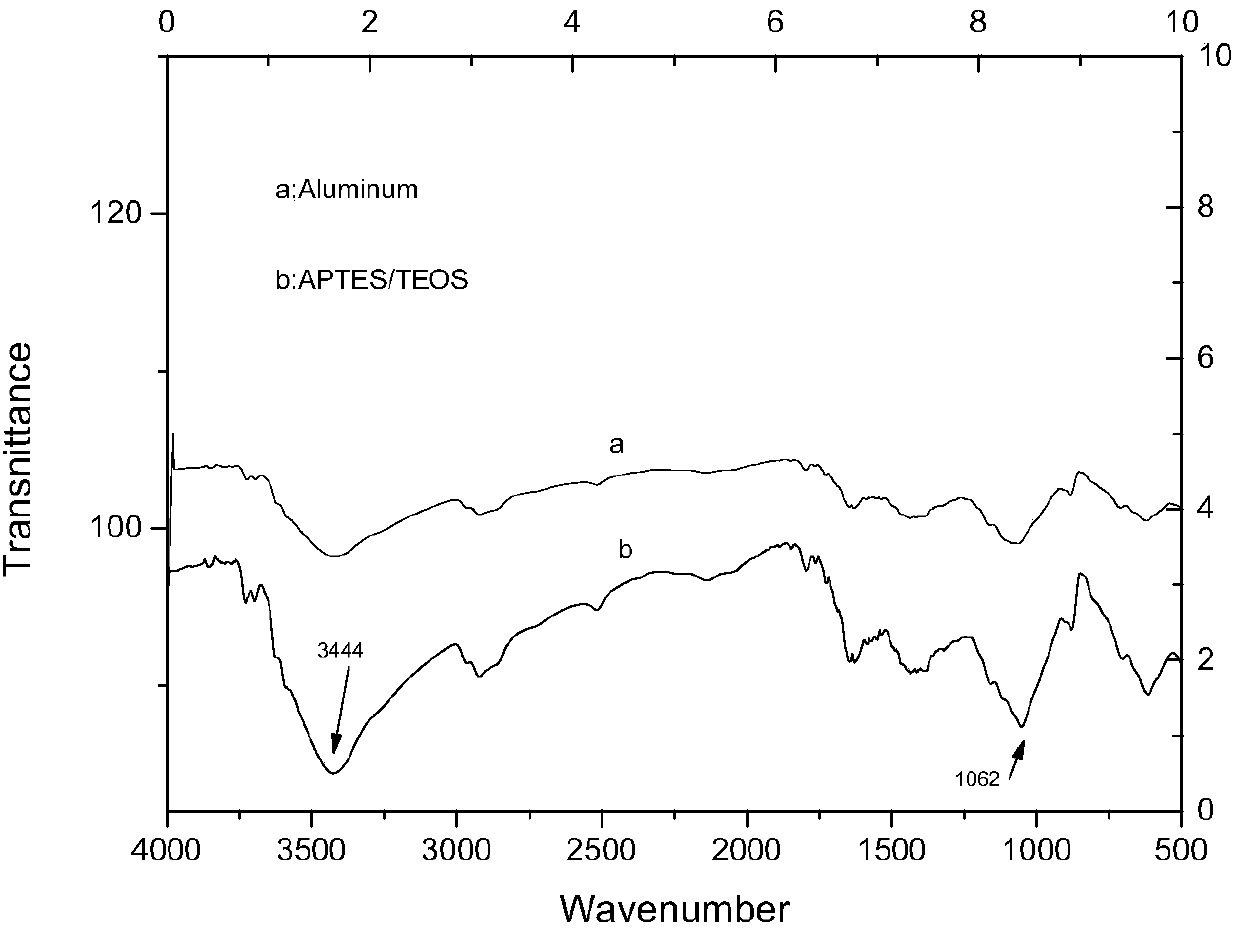

[0044] 1. Modification of aluminum pigment

[0045] 1a. Weigh 20 parts by mass of oily aluminum pigment, disperse evenly in 400 parts by mass of absolute ethanol, add 4 parts by mass of polyethylene glycol dropwise as a dispersant, and then ultrasonically treat for 40 minutes. After ultrasonic treatment, filter the aluminum pigment solution and use Rinse with absolute ethanol for 2 times to obtain alcohol-washed aluminum powder;

[0046] 1b. Add 12 parts by mass of tetraethyl orthosilicate and 18 parts by mass of aminopropyltriethoxysilane coupling agent to 250 parts by mass of absolute ethanol to obtain mixed solution A; add 30 parts by mass of ammonia water (mass concentration 25%) Add 60 parts by mass of deionized water to 250 parts by mass of absolute ethanol to obtain mixed solution B;

[0047] 1c. Add the alcohol-washed aluminu...

Embodiment 2

[0060] In the present embodiment, the method of utilizing 5-sulfosalicylic acid iron ion complex to color the aluminum pigment is as follows:

[0061] 1. Modification of aluminum pigment

[0062] 1a. Weigh 20 parts by mass of oily aluminum pigment, disperse evenly in 400 parts by mass of absolute ethanol, add 4 parts by mass of polyethylene glycol dropwise as a dispersant, and then ultrasonically treat for 40 minutes. After ultrasonic treatment, filter the aluminum pigment solution and use Rinse with absolute ethanol for 2 times to obtain alcohol-washed aluminum powder;

[0063] 1b. Add 12 parts by mass of tetraethyl orthosilicate and 18 parts by mass of aminopropyltriethoxysilane coupling agent to 250 parts by mass of absolute ethanol to obtain mixed solution A; add 30 parts by mass of ammonia water (mass concentration 25%) Add 60 parts by mass of deionized water to 250 parts by mass of absolute ethanol to obtain mixed solution B;

[0064] 1c. Add the alcohol-washed aluminu...

Embodiment 3

[0076] In the present embodiment, the method of utilizing 5-sulfosalicylic acid iron ion complex to color the aluminum pigment is as follows:

[0077] 1. Modification of aluminum pigment

[0078] 1a. Weigh 20 parts by mass of oily aluminum pigment, disperse evenly in 400 parts by mass of absolute ethanol, add 4 parts by mass of polyethylene glycol dropwise as a dispersant, and then ultrasonically treat for 40 minutes. After ultrasonic treatment, filter the aluminum pigment solution and use Rinse with absolute ethanol for 2 times to obtain alcohol-washed aluminum powder;

[0079] 1b. Add 12 parts by mass of tetraethyl orthosilicate and 18 parts by mass of aminopropyltriethoxysilane coupling agent to 250 parts by mass of absolute ethanol to obtain mixed solution A; add 30 parts by mass of ammonia water (mass concentration 25%) Add 60 parts by mass of deionized water to 250 parts by mass of absolute ethanol to obtain mixed solution B;

[0080] 1c. Add the alcohol-washed aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com