Large-flow engine oil pump of internal combustion

A technology of internal combustion engine and oil pump, which is applied to machines/engines, liquid fuel engines, pumps, etc., can solve the problems of reduced performance and service life, small volume ratio, rapid oil quality decline, etc., to reduce user maintenance costs, lubrication The effect of function enhancement and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

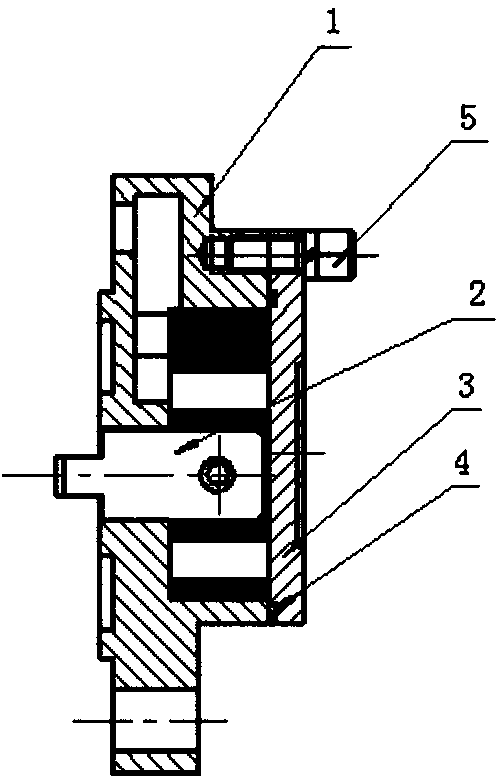

[0028] In this embodiment, the model is S1110 oil pump as an example, such as figure 1 , 2 Shown:

[0029] The S1110 engine oil pump in this embodiment includes a pump body 1 , a rotor assembly 2 , a pump cover 3 and a seal 4 .

[0030] The pump body 1 is connected to the pump cover 3, and a rotor cavity is formed between the pump body 1 and the pump cover 3; the rotor assembly 2 is located in the aforementioned rotor cavity; the seal 4 is arranged at the joint between the pump cover 3 and the pump body 1 .

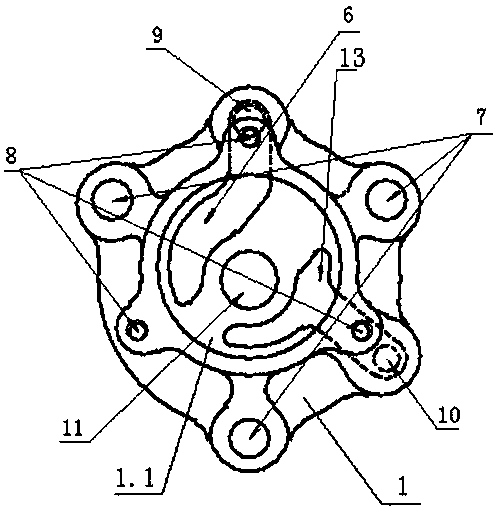

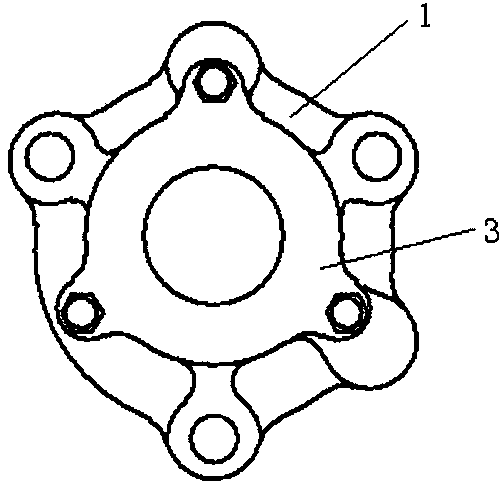

[0031] Such as image 3 shown. The cross section of the pump body 1 is in the shape of an irregular arc. Pump body 1HT250 casting; the outer peripheral wall of pump body 1 is provided with oil inlet hole 9, oil outlet hole 10, oil pump installation screw hole 7 and pump cover installation screw hole 8; pump body 1 is provided with a concave stepped cavity 1.1; the wall thickness of the concave stepped cavity 1.1 on the pump body 1 is 23mm; the concave stepped cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com