Boiler tube abnormal pressure detection system based on PTG502-CAN

A detection system and CAN bus technology, applied in the field of detection systems, can solve the problem of low accuracy of abnormal pressure detection, achieve the effects of good scalability and stability, easy to use in large quantities, and low design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

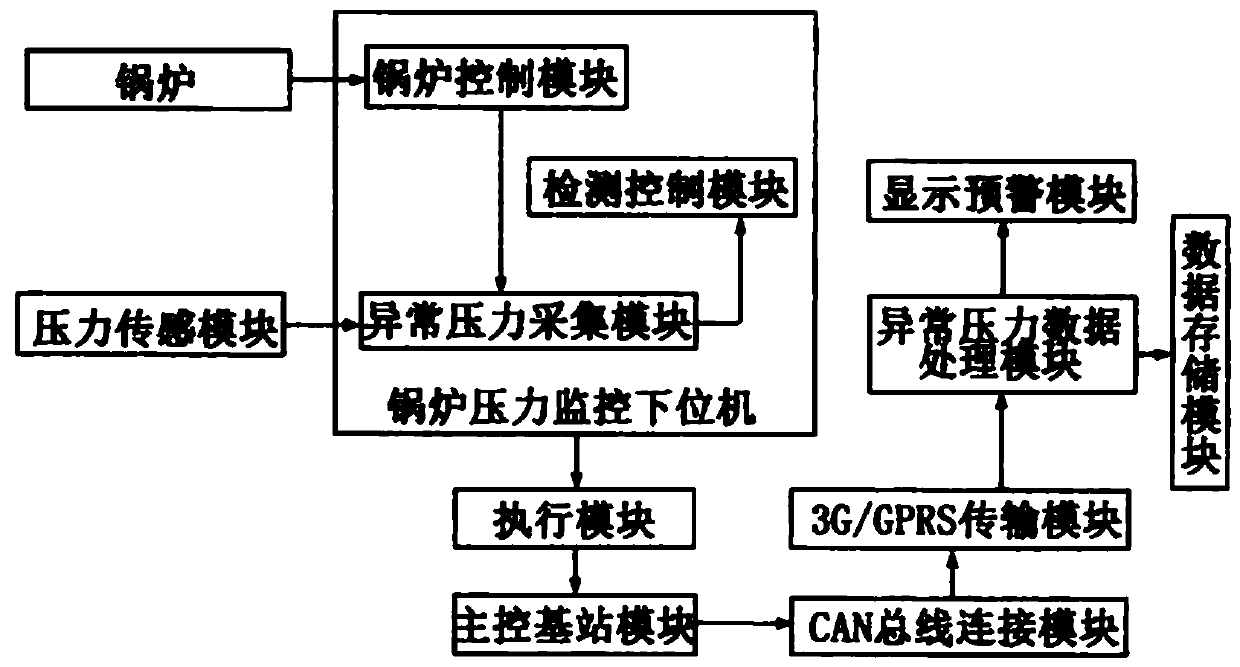

[0023] like figure 1 As shown, the boiler pipeline abnormal pressure detection system based on PTG502-CAN consists of a boiler module, a boiler control module, a detection control module, an abnormal pressure acquisition module, a pressure sensor module, a main control base station module, an execution module, and a CAN bus connection module 3G / It is composed of GPRS transmission module, abnormal pressure data processing module, display and early warning module, data storage module and other modules. The entire network adopts a distributed network control system, and the detection network connects the control nodes of multiple main control base stations with CAN bus. Each control node is connected to multiple actuators, and flexibly add or delete control nodes or pressure actuators according to the different lengths and distributions of the pipelines, so that the pipeline pressure detection network has good scalability and can be implemented according to actual needs For dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com