A fuel-fired kiln flue gas waste heat utilization system

A technology for flue gas waste heat and oil-fired furnaces, applied in furnaces, furnace components, waste heat treatment, etc., can solve problems such as energy waste, poor atomization quality, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

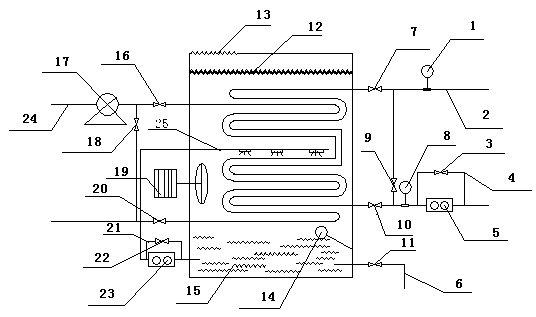

[0019] Such as figure 1 As shown, the waste heat utilization system of the oil-fired furnace flue gas includes a flue gas system, an oil circuit system, a water circulation system, a fan disturbance system and a failure emergency system. The flue gas system includes a gas valve I16, an induced draft fan 17, a gas valve II20, The flue gas pipeline 24 and the flue gas coil, the oil system includes a thermometer I1, an oil pipe 2, a bypass valve I3, a bypass pipe I4, an oil pump 5, an oil valve I7, a flow meter 8, an oil valve II10 and an oil coil , the water circulation system includes a water outlet pipe 6, a temperature control valve 11, a water eliminator 12, a liquid level controller 14, a water tank 15, a bypass pipe II21, a bypass valve II22, a water pump 23 and a water separator 25, and the fan disturbance system includes Induced fan 17, failure emergency system includes oil valve III9 and air valve III18;

[0020] The flue gas coils in the flue gas system and the oil ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com