MVR (mechanical vapor recompression) evaporator structure with integral gas-liquid separation structure

A gas-liquid separator, gas-liquid separation technology, applied in the direction of evaporator accessories, evaporation, separation methods, etc., can solve problems such as stringing in, no defoaming device, and increased equipment footprint, so as to reduce the hidden danger of damage , Reduce floor space, facilitate maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

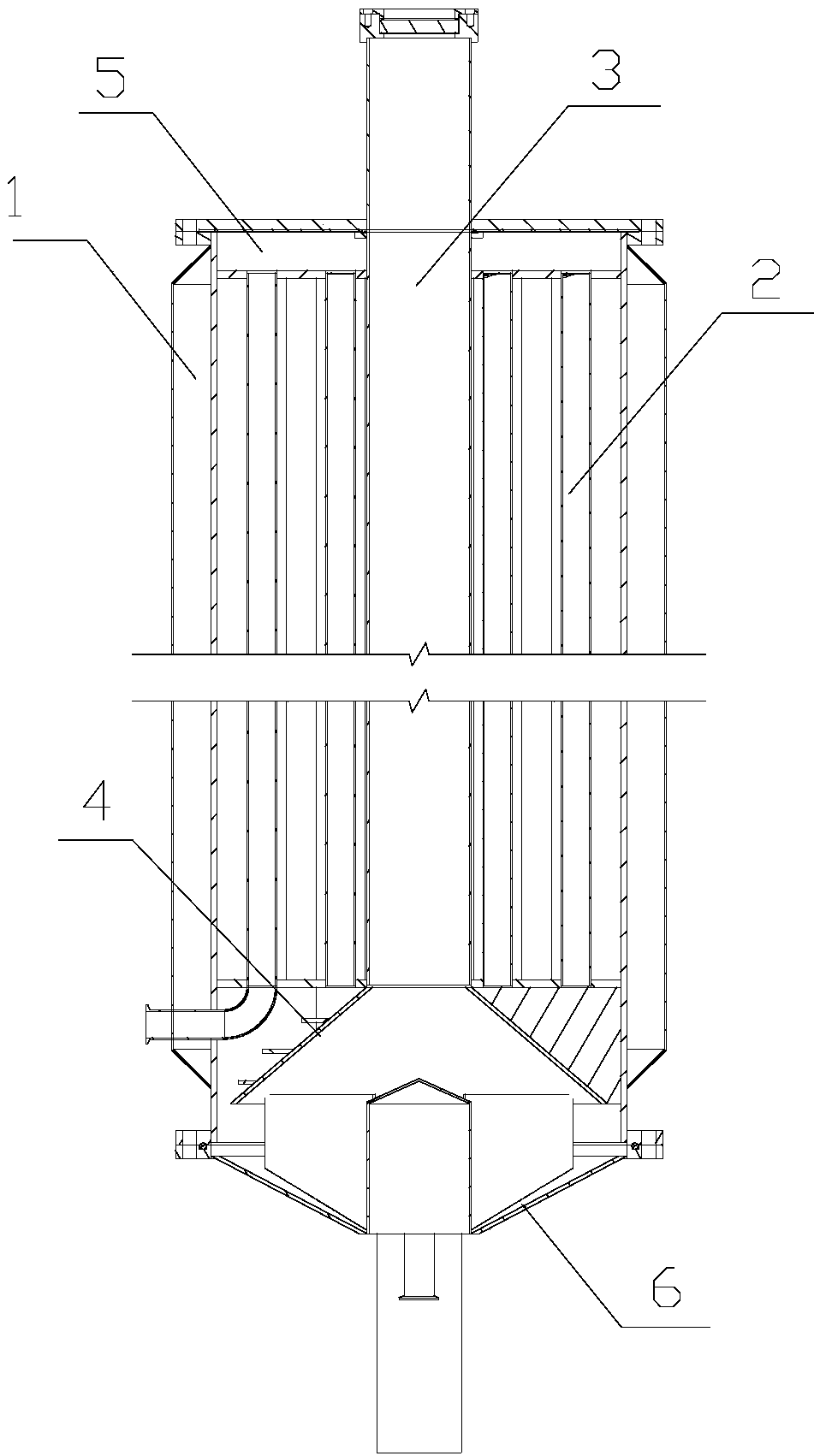

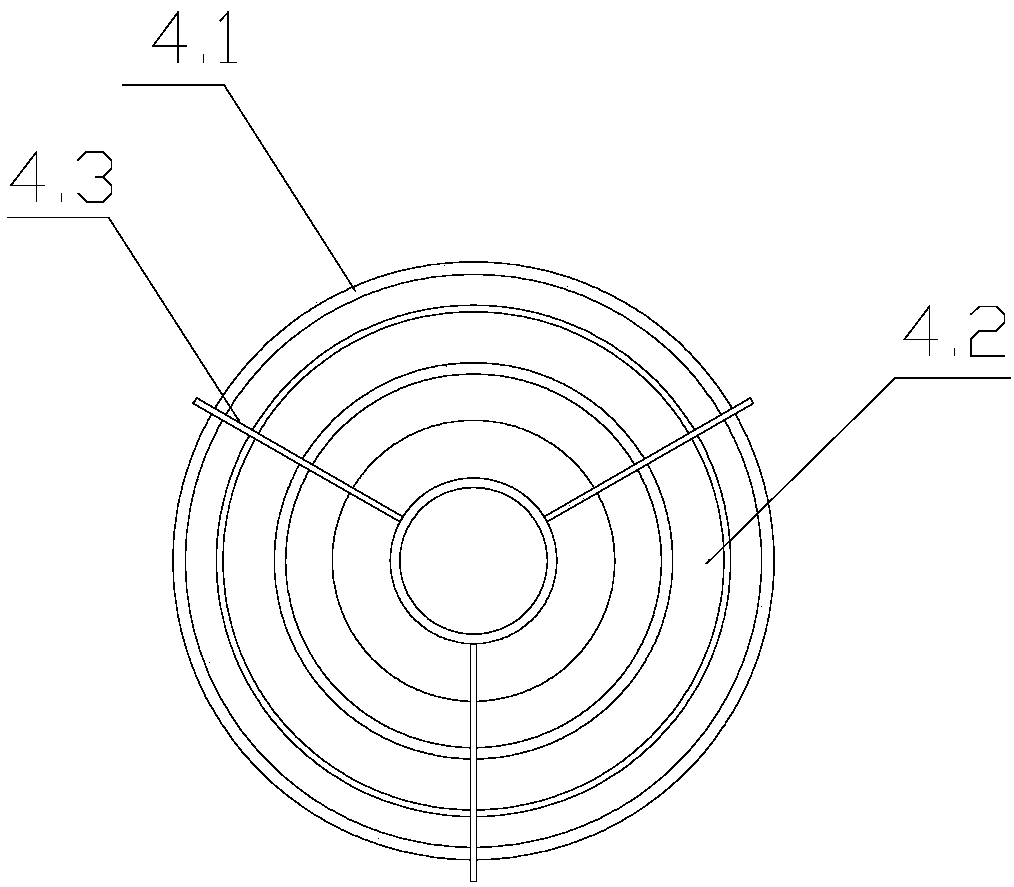

[0034] Such as figure 1 As shown, the present invention relates to an MVR evaporator structure with an integrated gas-liquid separation structure, including a shell 1, and the inner cavity surrounded by the shell 1 is a closed cavity, and is arranged inside the shell 1 There is an evaporating tube bundle 2, and the top of the evaporating tube bundle 2 is a distribution chamber 5, and a secondary steam tube 3 is provided at the central axis of the housing 1 to discharge the steam generated during evaporation. The lower part of the casing 1 is provided with a defoaming device 4, and the material is sent into the casing 1 through the material distribution chamber 5, and flows along the outer walls of the evaporation tubes of the evaporation tube bundle 2 from top to bottom, forming a film naturally under the action of gravity, heating the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com