[0006] But it's not that simple

[0007] First, this

polydimethylsiloxane material, the material referred to by the acronym PDMS, itself is a strongly hydrophobic material, and microchannels are built on this material. The modification operation of the channel surface, then, after the overall

assembly is completed, that is, after the cover is covered, because the inner surface of the micro channel in the structure occupies most of the inner surface of the liquid flow channel, then the PDMS micro The strong hydrophobic characteristic of the inner surface of the channel is the decisive factor, which will make it very difficult for the polar liquid fine flow similar to the

aqueous solution to pass through, and its flow resistance is so large that even ordinary micropumps are difficult to push. Of course, If the cover sheet also chooses to use the PDMS material, then the problem is basically the same, with little difference; therefore, in the prior art, it is necessary to modify the inner surface of the microchannel on the PDMS material: Then , is this modification operation for the inner surface of the PDMS microchannel very troublesome? That's not the problem. What constitutes a serious technical problem is another problem: the PDMS

polymer molecules in the bulk phase of the PDMS material substrate have the characteristics of automatic

diffusion and migration to the surface. The characteristics of

polymer molecules diffusing and migrating to the surface automatically will make the modified state of the inner surface of the microchannel modified by the

surface modification unable to maintain for a long enough time, and the microgroove after

surface modification The maintenance time of the inner surface state of the channel is roughly only enough to complete the time required for the internal test experiment in the laboratory; in other words, the inner surface of the PDMS microchannel after

surface modification or surface modification is formed after modification The surface state of the surface does not last long, but quickly tends to or changes back to the surface state before the surface modification, and returns to the original strongly hydrophobic surface state in a relatively short period of time. Then, just imagine, Can such microfluidic chips be produced in large quantities, stored in large quantities, and widely promoted? The answer is obvious, that is, impossible

[0015] Third, as mentioned above, the inner surface of the PDMS microchannel is strongly hydrophobic, and targeted

surface chemical modification or

surface chemical modification is difficult to last. It is effective to use it within a short period of time; if the relatively short

expiration date has passed and it is still used forcibly, since the surface state is already close to the hydrophobic state, there must be a comparison between using the conventional

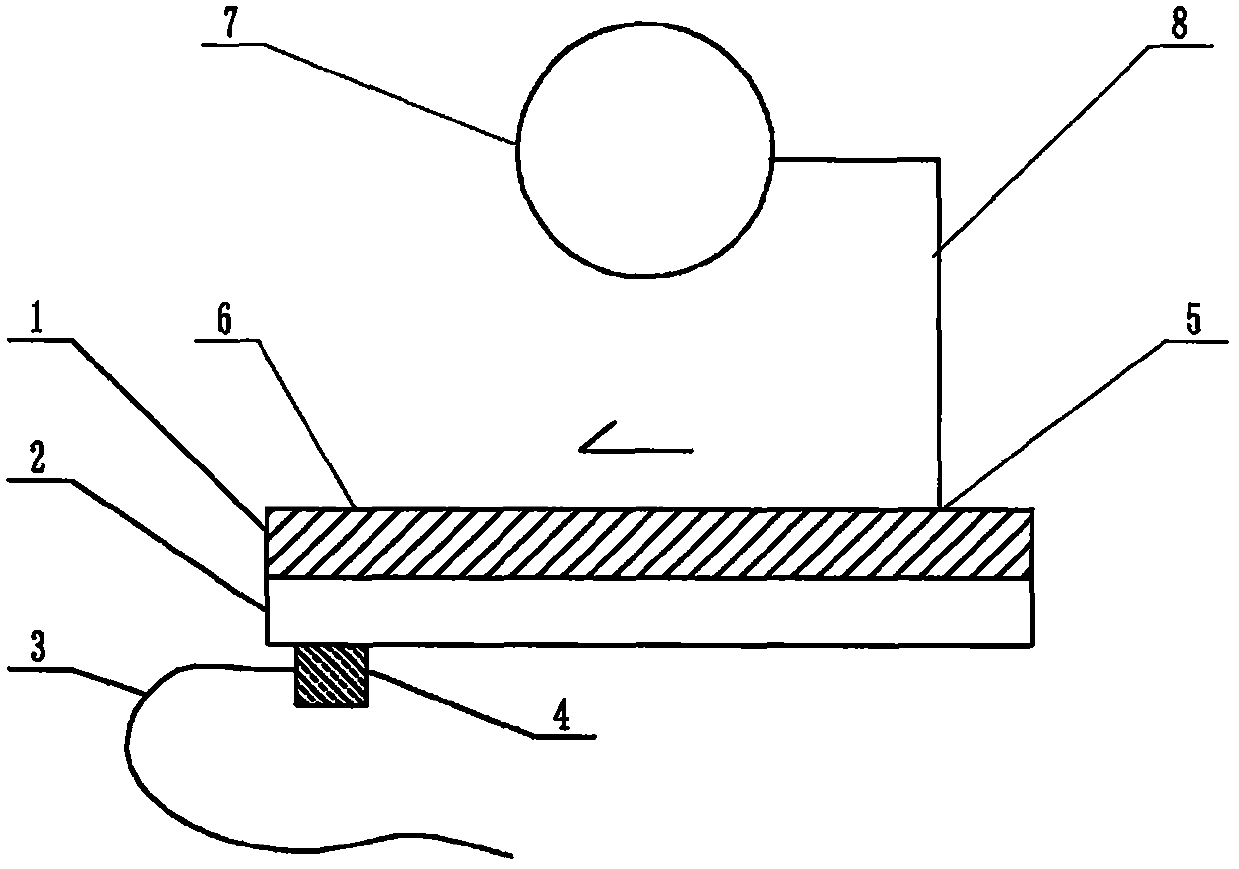

micropump to drive the sample liquid flow. Large flow resistance, in this way, the sample liquid can only be forced to flow in the target direction by increasing the pumping power and pumping pressure of the

micropump. Pumping pressure to pump the sample liquid flow will cause bubbling, puffing, twisting, and deformation of the microchannels at the sampling end of the substrate including the area near the sampling end, and, under such

high pressure conditions, The microgroove and its periphery at the sample inlet and its vicinity are also prone to peeling between the substrate and the

cover slip. In this case, the sample solution will enter between the substrate and the

cover slip formed after the peeling. This actually leads to the damage of the microfluidic

chip; of course, if the surface modification or the surface modification is not in place, it will also lead to the above-mentioned situation within the short customary validity period; In the case of simply using an external micropump for liquid flow drive, the above-mentioned problem always exists

As mentioned above, if no pre-operations such as surface modification or surface modification have been done at all, then the above-mentioned problem will be more serious, even if the microchannel bubbling at the injection end and its vicinity does not occur , puffing, twisting, deformation, and peeling between the substrate and the cover sheet, etc., just because the flow resistance is too large, the use of a high-pressure micropump may not be able to drive the sample liquid flow toward the terminal.

Login to View More

Login to View More  Login to View More

Login to View More