Microfluidic chip apparatus using two-drive mode coupled operation and containing hydrophobic substrate

A technology of a microfluidic chip and a driving method, applied in the field of analysis and testing, can solve the problems of microchannel bubbling substrate and cover sheet, the inner surface modification of PDMS microchannel, troublesome operation, large flow resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

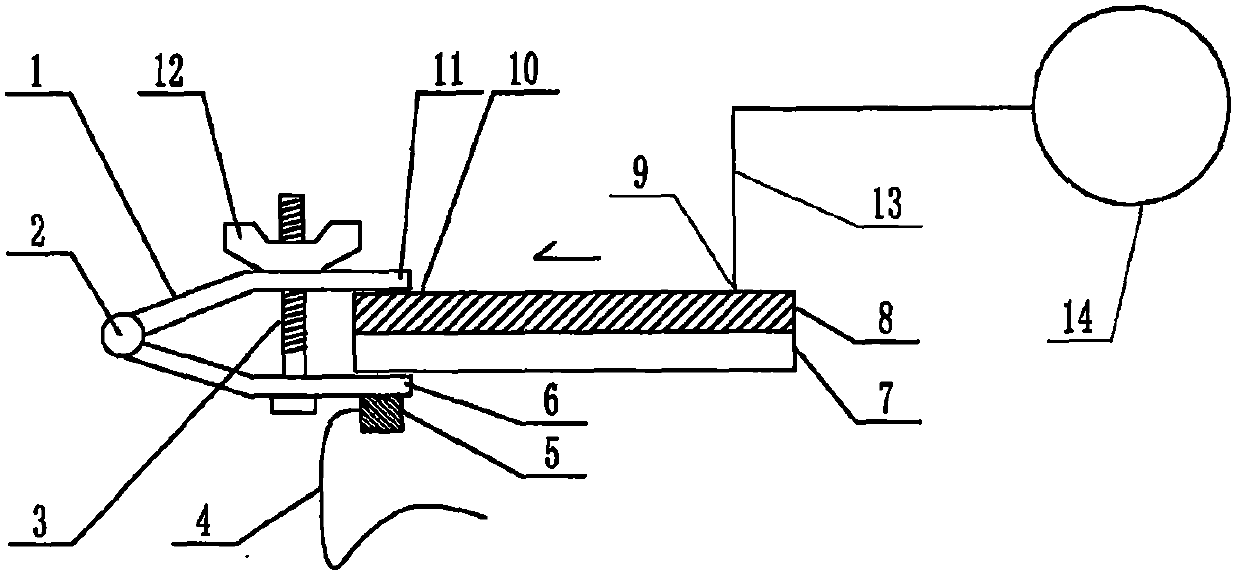

[0044] exist figure 1 In the shown embodiment of the present case, the structure of the device includes a microfluidic chip, and the structure of the microfluidic chip includes a substrate 8 and a cover sheet 7 that are attached to each other. The sampling end 9 of the sample liquid flow is far away from the terminal 10 where the sample liquid flows. The distance between the sampling end 9 and the terminal 10 is between 3 cm and 10 cm. The terminal 10 and the terminal liquid pool Linked together, the outline of the structure of the terminal liquid pool is pool-shaped, pit-shaped or cup-shaped, and the terminal liquid pool is used to receive the sample solution flowing to the terminal 10 through the internal pipeline of the microfluidic chip. The key point is , the substrate 8 is made of polydimethylsiloxane material, and the surface of the substrate 8 is a surface in a native form. The surface in a native form means that it has not undergone any surface chemical modification o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com