Pyrophosphate assisted method used for synthesis of high performance prussian blue analogous

A pyrophosphate, Prussian blue technology, applied in ferricyanide, metal cyanide, structural parts, etc., can solve the problems affecting the electrochemical sodium storage performance of Prussian blue, poor crystallinity of Prussian blue, etc., to achieve regular morphology and price. Low cost, simple and convenient synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

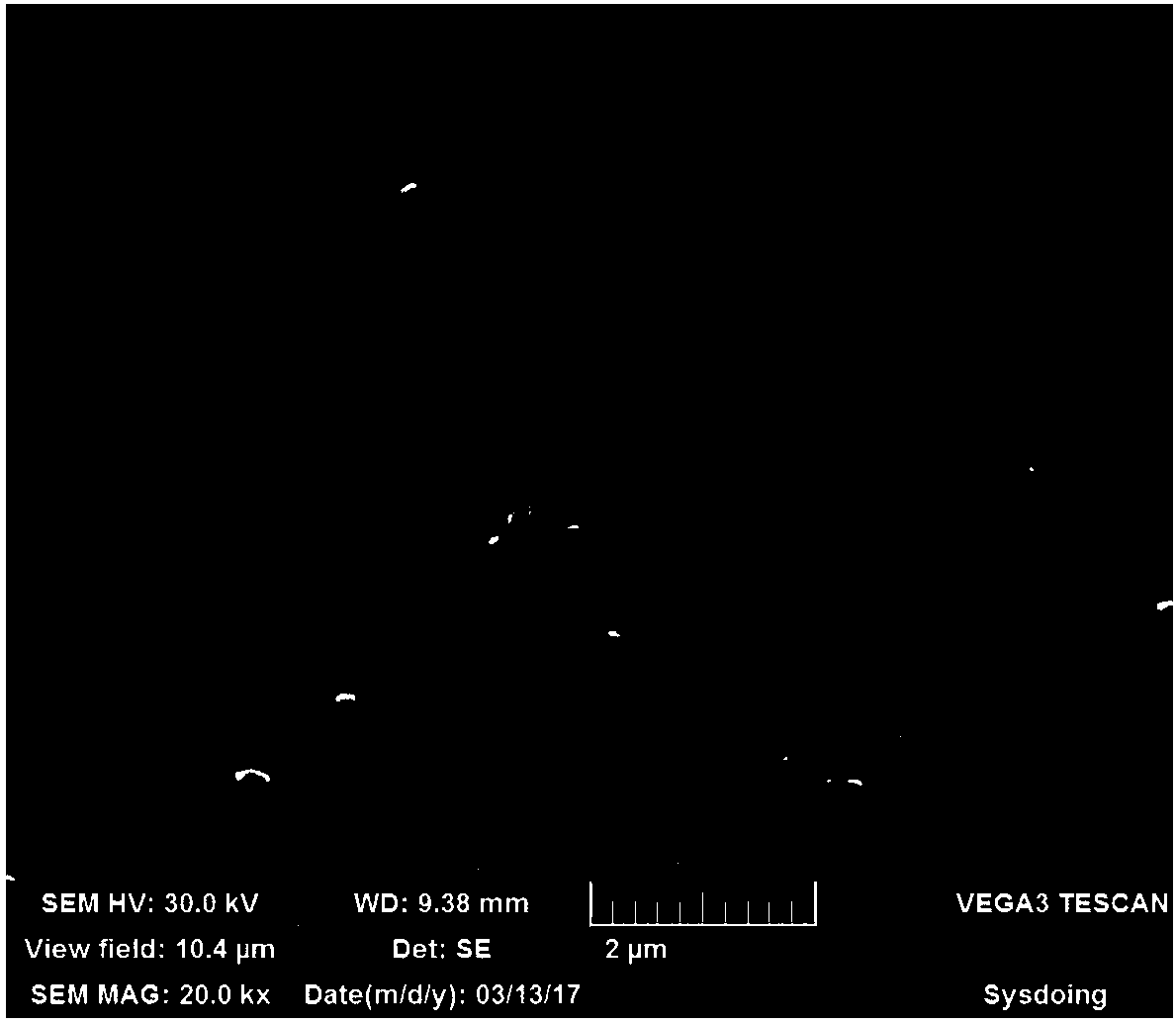

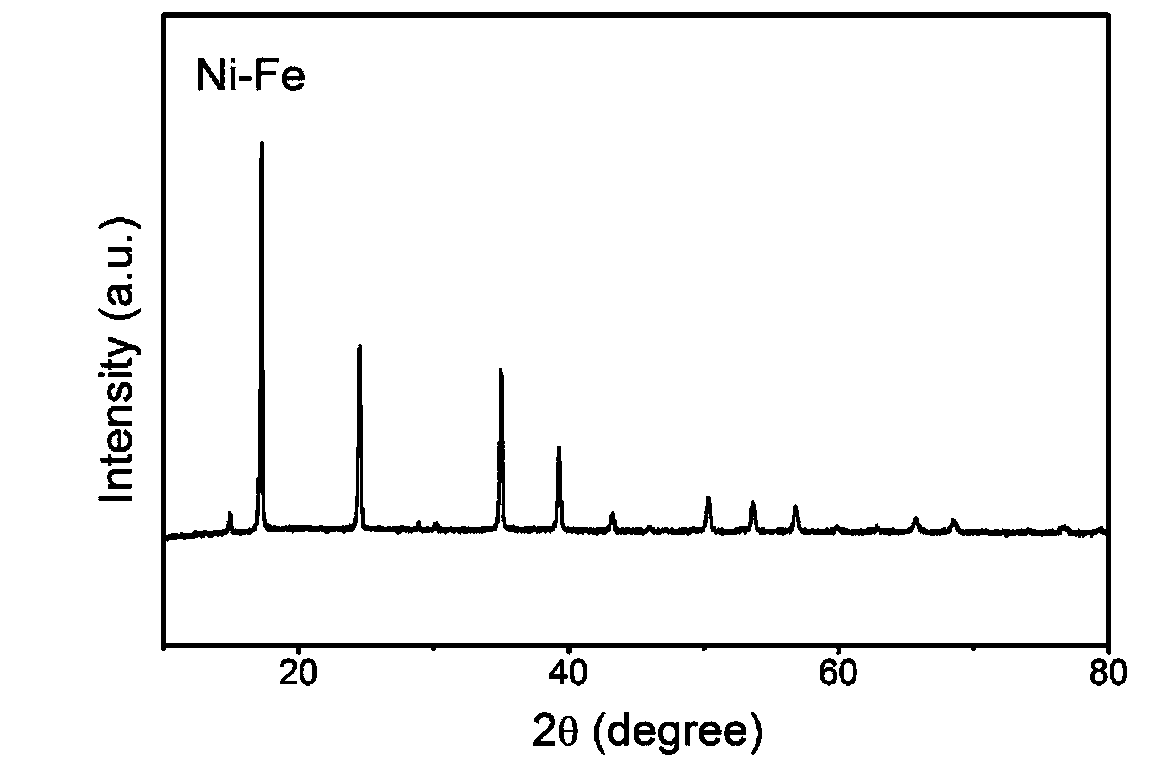

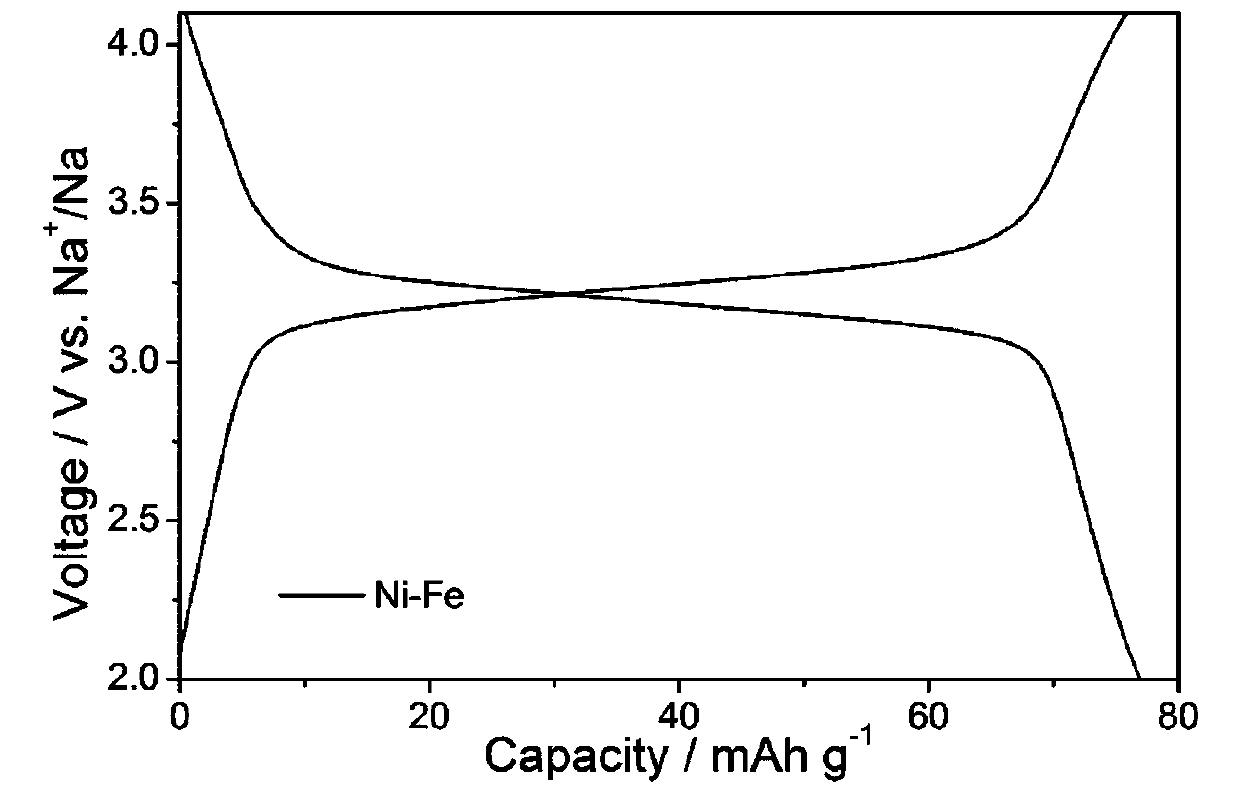

[0025] Embodiment one: if figure 1 , figure 2 Shown, a kind of preparation method of pyrophosphate assisted synthesis high-performance Prussian blue analogue, comprises the steps:

[0026] S100. Weigh 1mM (0.237g) nickel chloride and dissolve it in 20ml deionized water, stir until clarified, add 1mM sodium pyrophosphate, and continue stirring to obtain solution A;

[0027] S200. Weigh 0.5mM (0.165g) of potassium ferricyanide and add it into 50ml of deionized water and stir until clarified, then add 0.3g of PVP-K30 (polyvinylpyrrolidone-K30) and 10mM (0.584g) of sodium chloride and stir to obtain solution B;

[0028] S300. Use a peristaltic pump to add solution A dropwise to solution B while stirring at a rate of 1ml / min. After the addition is complete, stop stirring to obtain suspension C;

[0029] S400. Leave the suspension C to stand and age for 48 hours, filter out the light yellow precipitate obtained from aging, and use deionized water and absolute ethanol to alternate...

Embodiment 2

[0037] Embodiment two: a kind of preparation method of pyrophosphate assisted synthesis high-performance Prussian blue analogue, comprises the following steps:

[0038] S100. Weigh 0.5mM copper pyrophosphate and disperse it in 20ml deionized water, then add 0.5mM sodium pyrophosphate, and stir to obtain solution A;

[0039] S200. Weigh 0.3 g of sodium ferrocyanide and add it to 50 ml of deionized water, stir until clarified, then add 0.3 g of PVP-K30 and 10 mM (0.584 g) of sodium chloride, and stir to obtain solution B;

[0040] S300. Use a peristaltic pump to add solution A dropwise to solution B while stirring at a rate of 1ml / min. After the addition is complete, stop stirring to obtain suspension C;

[0041] S400. Leave the suspension C to stand and age for 120 hours, filter out the brick-red precipitate obtained from aging, and alternately wash the brick-red precipitate twice with deionized water and absolute ethanol, and then dry it at 80° C. for 12 hours. A golden-yello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com