Early strength agent used for concrete hollow bricks

A technology of early strength agent and hollow brick, which is applied in the field of building materials, can solve the problems of long demoulding time and low production efficiency, and achieve the effects of shortening demoulding time, improving work efficiency and reducing slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

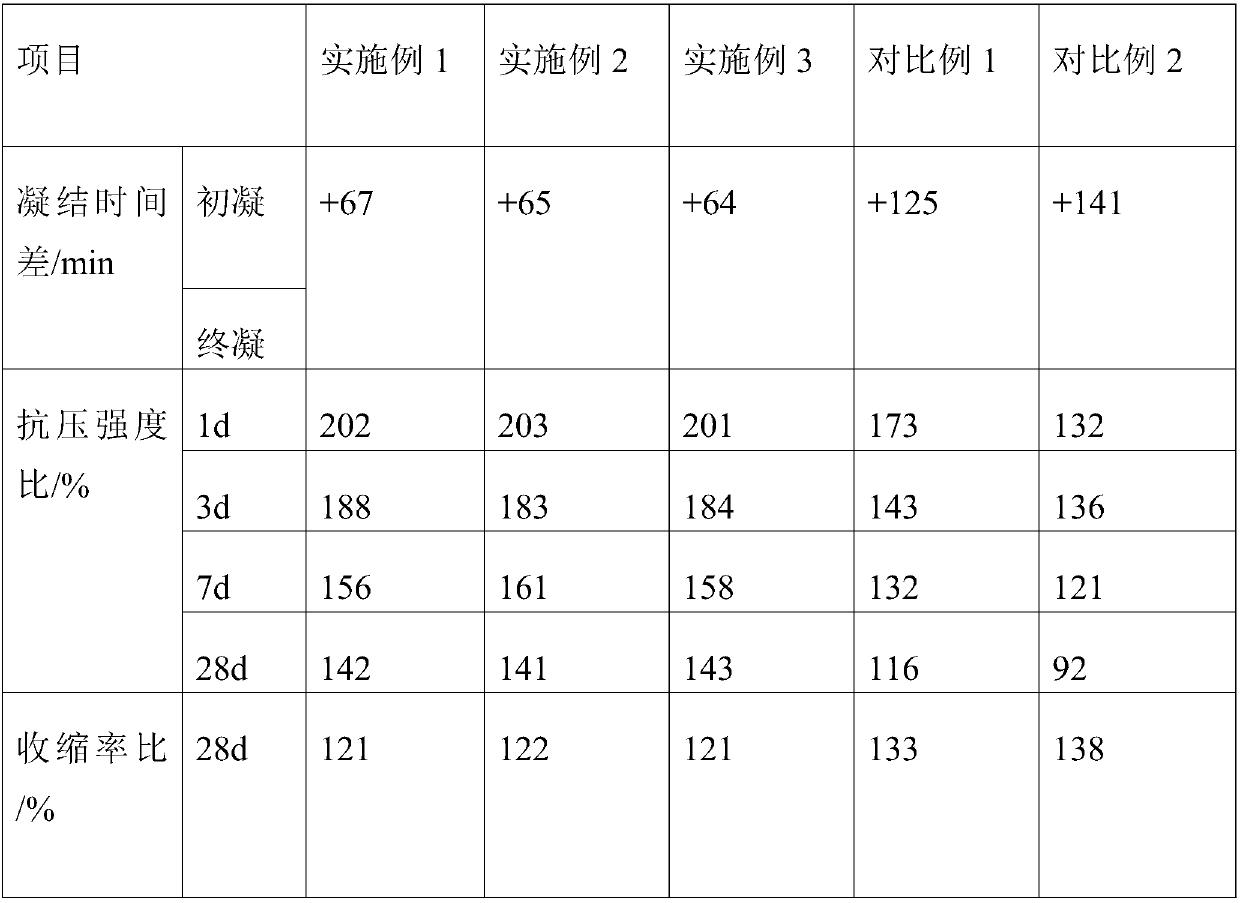

Examples

Embodiment 1

[0016] An early strength agent for concrete hollow bricks. In parts by weight, the early strength agent comprises the following raw materials: 5 parts of rosin, 4 parts of phenol, 3 parts of magnesium trisilicate, 7 parts of potassium hydrogen tartrate, 8 parts of triethanolamine, 2 parts of shale ash, 6 parts of methyl methacrylate, 9 parts of urea, 5 parts of trehalose, 12 parts of cellulose ether, 7 parts of calcium formate, 5 parts of isopropanol, 6 parts of soda, 3 parts of glycolic acid, kaolin 9 parts, 3 parts of p-toluenesulfonic acid and 8 parts of nano calcium carbonate.

[0017] The cellulose ether is ethyl cellulose and benzyl cellulose, and the mixing mass ratio is 1:1.

[0018] The strength accelerator prepared in this example is used to prepare concrete hollow bricks, and the mass ratio of the strength accelerator in the hollow concrete brick is as follows: early strength agent: cement is 3:100.

Embodiment 2

[0020] An early strength agent for concrete hollow bricks, in parts by weight, the early strength agent comprises the following raw materials: 2 parts of rosin, 5 parts of phenol, 1 part of magnesium trisilicate, 11 parts of potassium hydrogen tartrate, 11 parts of triethanolamine, 3 parts of shale ash, 5 parts of methyl methacrylate, 13 parts of urea, 3 parts of trehalose, 15 parts of cellulose ether, 6 parts of calcium oxalate, 2 parts of isopropanol, 8 parts of soda, 5 parts of glycolic acid, kaolin 7 parts, 4 parts of p-toluenesulfonic acid and 6 parts of nano calcium carbonate.

[0021] The cellulose ether is carboxymethyl cellulose and ethyl cellulose, and the mixing mass ratio is 1:1.

[0022] The strength accelerator prepared in this example is used to prepare concrete hollow bricks. The mass ratio of the strength accelerator in the hollow concrete brick is 1:100 of strength accelerator: cement.

Embodiment 3

[0024] An early strength agent for concrete hollow bricks. In parts by weight, the early strength agent comprises the following raw materials: 9 parts of rosin, 3 parts of phenol, 5 parts of magnesium trisilicate, 4 parts of potassium hydrogen tartrate, 5 parts of triethanolamine, 1 part of shale ash, 9 parts of methyl methacrylate, 7 parts of urea, 7 parts of trehalose, 9 parts of cellulose ether, 10 parts of calcium oxalate, 7 parts of isopropanol, 3 parts of soda, 1 part of glycolic acid, kaolin 12 parts, 1 part of p-toluenesulfonic acid and 13 parts of nano calcium carbonate.

[0025] The cellulose ether is hydroxyethyl methylcellulose.

[0026] The strength accelerator prepared in this example is used to prepare concrete hollow bricks. The mass ratio of the strength accelerator in the hollow concrete brick is 5:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com