Weather-resistant powder coating and preparation process thereof

A powder coating and open flame technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of poor weather resistance of epoxy resin, high VOC emission, coating collapse, etc., to improve high temperature resistance and open flame burning performance, improve Anti-aging and weather resistance, the effect of increasing cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]

[0033]

[0034] Preparation Process:

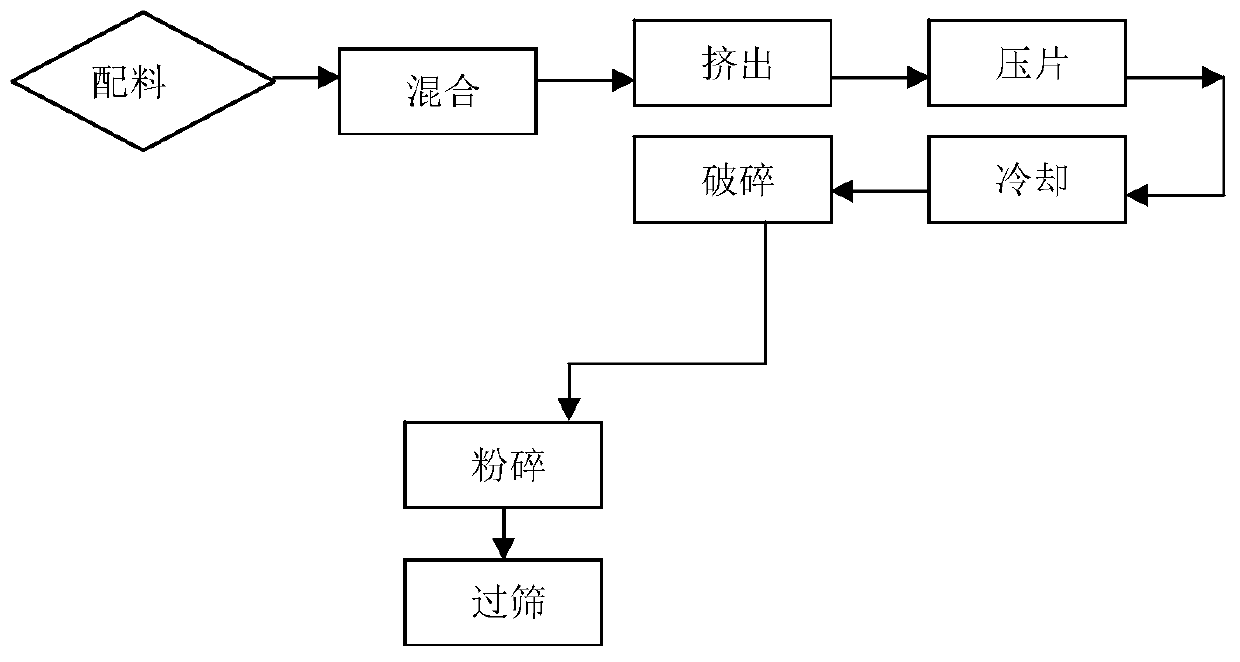

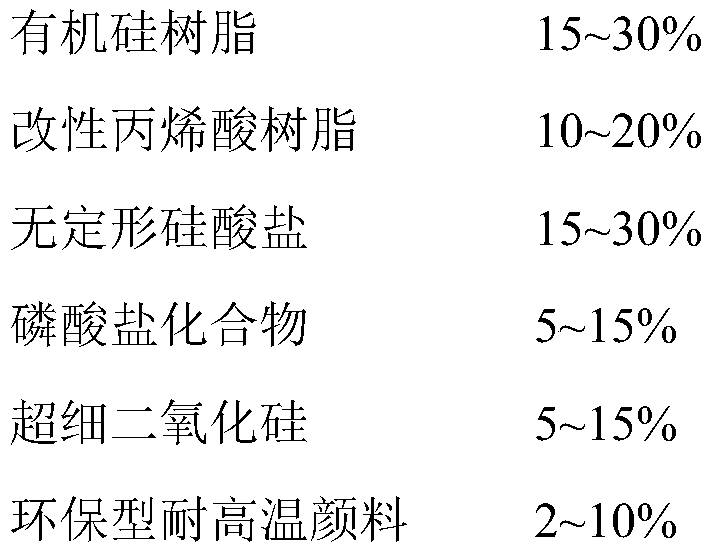

[0035] (1) Weigh silicone resin, modified acrylic resin, amorphous silicate, phosphate compound, ultrafine silica, high temperature resistant pigment, caprolactam double-end blocked isocyanate and auxiliary agent according to the proportion, fully mix and crush;

[0036] (2) The crushed material enters the extruder to be melted and extruded;

[0037] (3) The extruded material is packed after tableting, cooling, crushing, crushing and sieving.

Embodiment 2

[0039] The difference with embodiment 1 is:

[0040]

[0041] The preparation process is the same as in Implementation 1.

Embodiment 3

[0043] The difference with embodiment 1 is:

[0044]

[0045]

[0046] The preparation process is the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com