Plant liquid extraction and activated carbon production and processing equipment and technology thereof

A technology of activated carbon production and processing equipment, which is applied in the direction of fat oil/fat production, fat generation, carbon compounds, etc., which can solve the problems of cost increase, single production, and insufficient utilization of process systems, etc., to achieve the effect of reducing consumption and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

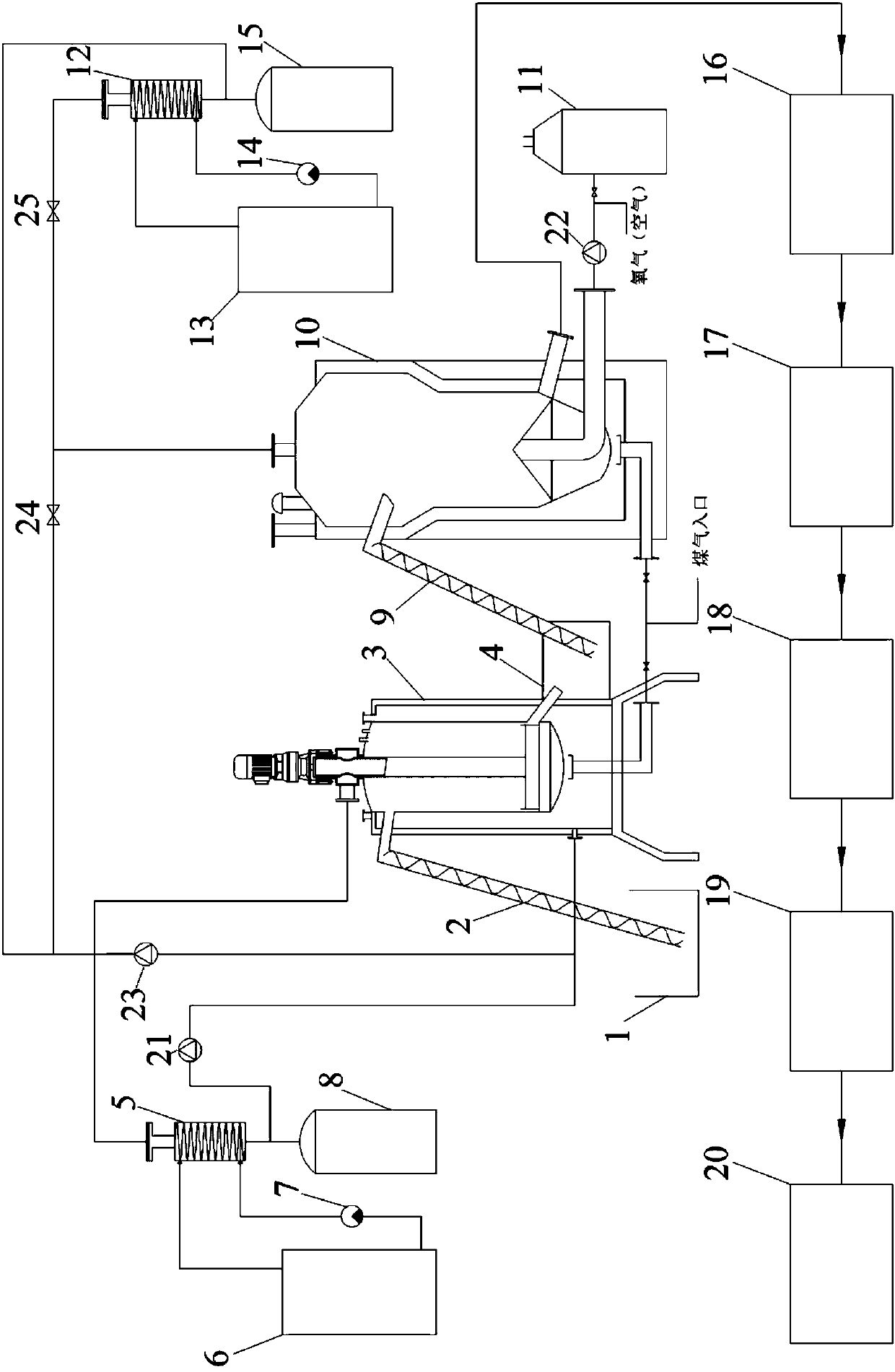

[0034] A plant medicinal solution extraction and activated carbon production and processing process, characterized in that the process includes the following steps:

[0035] In the first step, the hawthorn nucleus raw materials that have been removed from sand and gravel impurities and simply selected are added to the raw material warehouse 1; the first screw feeder 2 and the raw material inlet of the fumigation furnace 3 are opened, and the hawthorn nucleus raw materials are transported to In the fumigation furnace 3, the volume of the hawthorn nucleus material accounts for 1 / 2 of the volume of the evaporation tank in the fumigation furnace 3; close the first screw feeder 2;

[0036] In the second step, the fruit core fumigation extraction system works, the activated carbon production system and the activated carbon processing system are closed; the raw material inlet of the fumigation furnace 3 is closed, and the evaporation flue gas outlet is opened; the gas inlet is opened, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com