Magnesium alloy profile heat treatment deformation control device and control method

A control device and magnesium alloy technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., to achieve the effect of reducing difficulty, ensuring reasonable product rate, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 is a kind of preferred implementation mode of the present application:

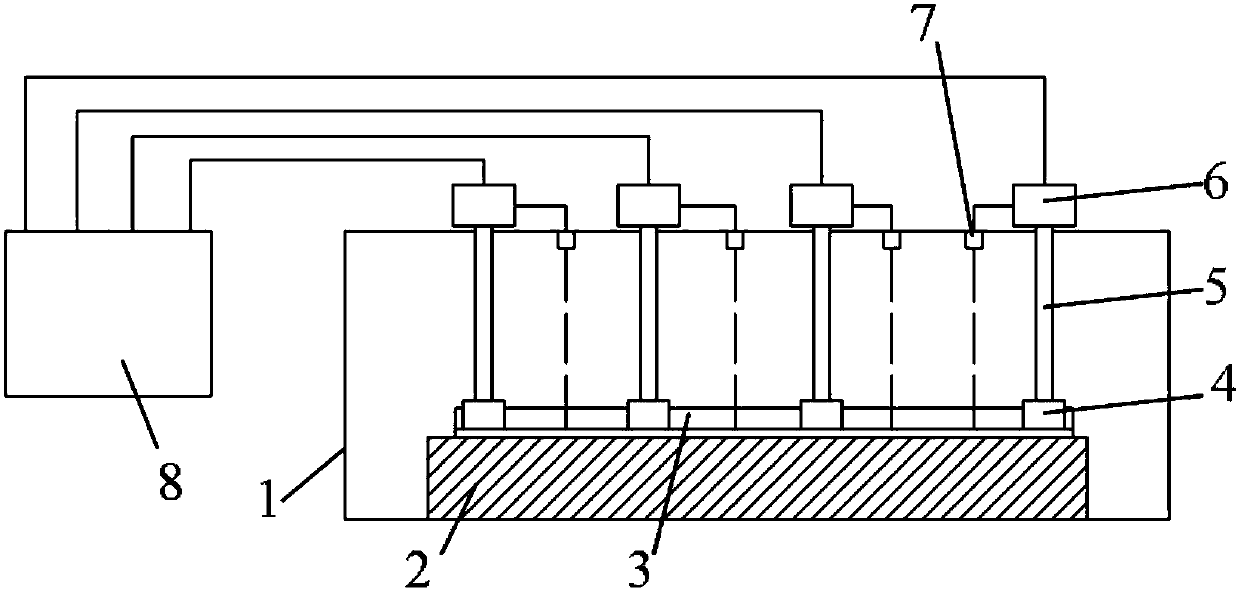

[0037] Such as figure 1As shown, a heat treatment deformation control device for magnesium alloy profiles includes: a heat treatment platform 2, a clamping device 4, a hydraulic power mechanism 6, a connecting rod mechanism 5, a deformation detection device 7 and a control unit 8. The heat treatment platform 2 is located at the heat treatment In the furnace 1, the clamping device 4 is located above the heat treatment platform 2, and is connected to the hydraulic power mechanism 6 through the linkage mechanism 5, and the deformation detection device 7 is located on the hydraulic power mechanism 6- On the side, the clamping device 4 is provided with a pressure detection device, the pressure detection device, the deformation detection device 7 and the hydraulic power mechanism 6 are all connected to the control unit 8, and the deformation detection device 7 is a magnesium alloy The local...

Embodiment 2

[0045] Embodiment 2 is another preferred real-time mode of the present invention:

[0046] This embodiment introduces a method for controlling heat treatment deformation of magnesium alloy profiles using the above-mentioned device. The method includes the following steps:

[0047] 1) Place the magnesium alloy profile on the heat treatment platform in the heat treatment furnace, adjust the applied force of each hydraulic cylinder in the hydraulic power mechanism, so that the clamping force of each clamping block on the corresponding part of the magnesium alloy profile is consistent;

[0048] 2) Each deformation detection device detects the deformation displacement of its corresponding magnesium alloy profile in real time, and transmits the detected deformation results to the control unit;

[0049] 3) The control unit judges whether there is abnormal deformation in each part of the magnesium alloy profile according to the detection results. If there is no abnormal deformation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com