On-site coating and pre-flocculation modification method for paper making filler

A paper-making filler and coating technology, which is applied in the field of papermaking, can solve the problems of paper opacity reduction, filler pre-flocculation size and distribution are difficult to control, etc., and achieve high strength and increase ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

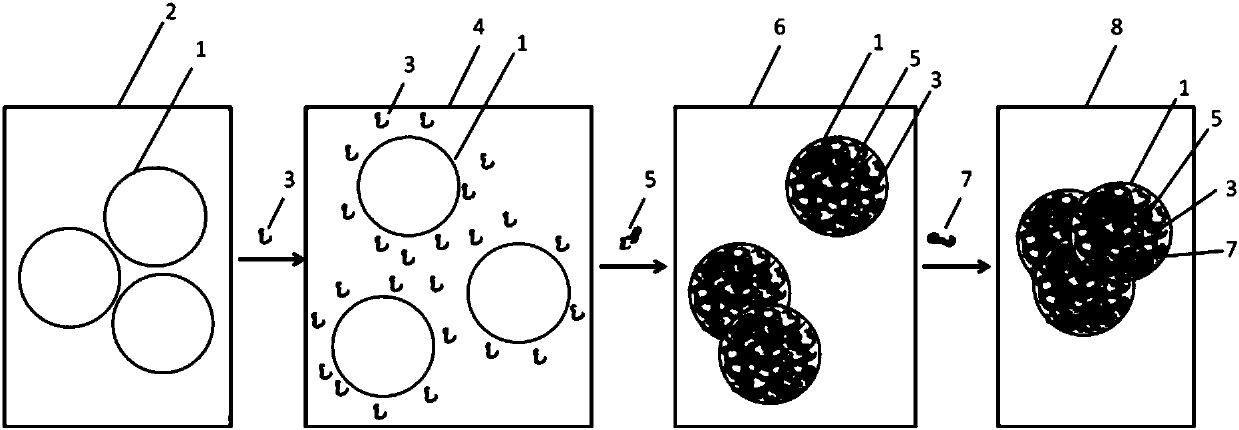

[0039] see figure 1 , figure 1 This is the working principle diagram of a method for on-site coating and pre-flocculation modification of papermaking filler provided by the embodiment of the present invention. Taking the modification of calcium carbonate filler as an example, the preparation method of on-site coating and pre-flocculation filler in this embodiment is shown. include:

[0040] The first step: take the liquid high concentration suspension calcium carbonate (CaCO 3 ) Filler 1, add an appropriate amount of water to dilute to 50 g of a suspension with a concentration of 30%, stir well to obtain unmodified CaCO 3 System 2.

[0041] The second step: to the unmodified CaCO 3 Add 0.9 mL of anionic polyacrylamide (APAM) 3 solution with a concentration of 18.8 g / L to system 2, and stir well to obtain CaCO 3 / APAM system4.

[0042] Step 3: To CaCO 3 Add 28 mL of cationic starch (CSt) 5 solution with a concentration of 5.5 g / L to the APAM system 4, and stir well to ob...

Embodiment 2

[0058] A method for on-site coating and pre-flocculation modification of papermaking filler is characterized by comprising the following steps:

[0059] 1) Coating: First disperse the paste kaolin filler in water to form a filler suspension, then add the polyelectrolyte A solution to the filler suspension and mix for 7 minutes, and then add the polyelectrolyte B solution and mix for 7 minutes to make the filler surface It is coated with a loosely structured polyelectrolyte composite formed by polyelectrolyte A and polyelectrolyte B to obtain a filler-coated body.

[0060] 2) Pre-flocculation: add the polyelectrolyte C solution and mix evenly, so that a larger size of filler-coated pre-flocculation is generated between the filler-coated bodies.

[0061] The combination of the polyelectrolytes A, B, and C is anionic polyacrylamide / cationic chitosan / cationic polyacrylamide. The usage amount of the polymer electrolyte A is 0.50 wt % of the filler, the usage amount of the polymer ...

Embodiment 3

[0063] A method for on-site coating and pre-flocculation modification of papermaking filler is characterized by comprising the following steps:

[0064] 1) Coating: First disperse the talc aqueous solution in water to form a filler suspension, then add the polyelectrolyte A solution to the filler suspension and mix for 3 minutes, and then add the polyelectrolyte B solution and mix for 3 minutes, so that the surface of the filler is coated. The polyelectrolyte composite with loose structure formed by polyelectrolyte A and polyelectrolyte B is coated to obtain a filler coated body.

[0065] 2) Pre-flocculation: add the polyelectrolyte C solution and mix evenly, so that a larger size of filler-coated pre-flocculation is generated between the filler-coated bodies.

[0066] Wherein, the combination of the polyelectrolytes A, B, and C is anionic polyacrylamide / cationic guar gum / cationic polyacrylamide. The usage amount of the polymer electrolyte A is 0.25 wt % of the filler, the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com