A Gravity Maintenance Method for Master-Slave Heterogeneous Manipulators

A technology of manipulators and main hands, which is applied in the direction of manipulators, manufacturing tools, complex mathematical operations, etc., can solve the problems that do not take into account the gravity maintenance technology of manipulators, achieve the effects of rich motion modes, less CPU usage, and improved compensation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for maintaining gravity of a master-slave heterogeneous manipulator, comprising the following steps:

[0028] Offline quality estimation, respectively define the three-dimensional base coordinate system of the main hand and the slave hand work space of the manipulator; select the cube in the main hand base coordinate system, and divide its interior into several equal cube blocks; set the cube block vertices The initial mass of the manipulator is controlled to move the main hand of the manipulator to each vertex and the estimated mass of the main hand at each vertex is estimated by the recursive algorithm of proportional differential control to obtain the mass value in the real-time online gravity compensation;

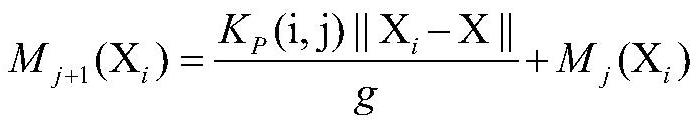

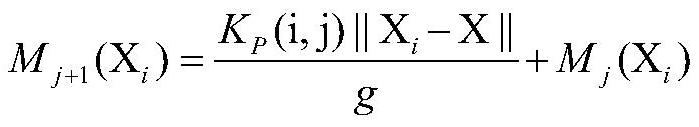

[0029] Real-time online interpolation gravity compensation, according to the cube blocks divided in the offline quality estimation process to obtain the coordinate position of each vertex of the cube block where the main hand of the manipulator is locate...

Embodiment 2

[0032] A method for maintaining gravity of a master-slave heterogeneous manipulator, comprising the following steps:

[0033] Offline quality estimation, respectively define the three-dimensional base coordinate system of the main hand and the slave hand work space of the manipulator; select the cube in the main hand base coordinate system, and divide its interior into several equal cube blocks; set the cube block vertices The initial mass of the manipulator is controlled to move the main hand of the manipulator to each vertex and the estimated mass of the main hand at each vertex is estimated by the recursive algorithm of proportional differential control to obtain the mass value in the real-time online gravity compensation;

[0034]Real-time online interpolation gravity compensation, according to the cube blocks divided in the offline quality estimation process to obtain the coordinate position of each vertex of the cube block where the main hand of the manipulator is located...

Embodiment 3

[0049] A method for maintaining gravity of a master-slave heterogeneous manipulator, comprising the following steps:

[0050] Offline quality estimation, respectively define the three-dimensional base coordinate system of the main hand and the slave hand work space of the manipulator; select the cube in the main hand base coordinate system, and divide its interior into several equal cube blocks; set the cube block vertices The initial mass of the manipulator is controlled to move the main hand of the manipulator to each vertex and the estimated mass of the main hand at each vertex is estimated by the recursive algorithm of proportional differential control to obtain the mass value in the real-time online gravity compensation;

[0051] Real-time online interpolation gravity compensation, according to the cube blocks divided in the offline quality estimation process to obtain the coordinate position of each vertex of the cube block where the main hand of the manipulator is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com