Lightweight high-flexibility mobile cable

A mobile cable, highly flexible technology, applied in power cables, insulated cables, flexible cables, etc., can solve the problems of short service life, frequent replacement, high motor power, etc., to reduce the power loss of the whole machine and the overall wiring. The effect of simplicity and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

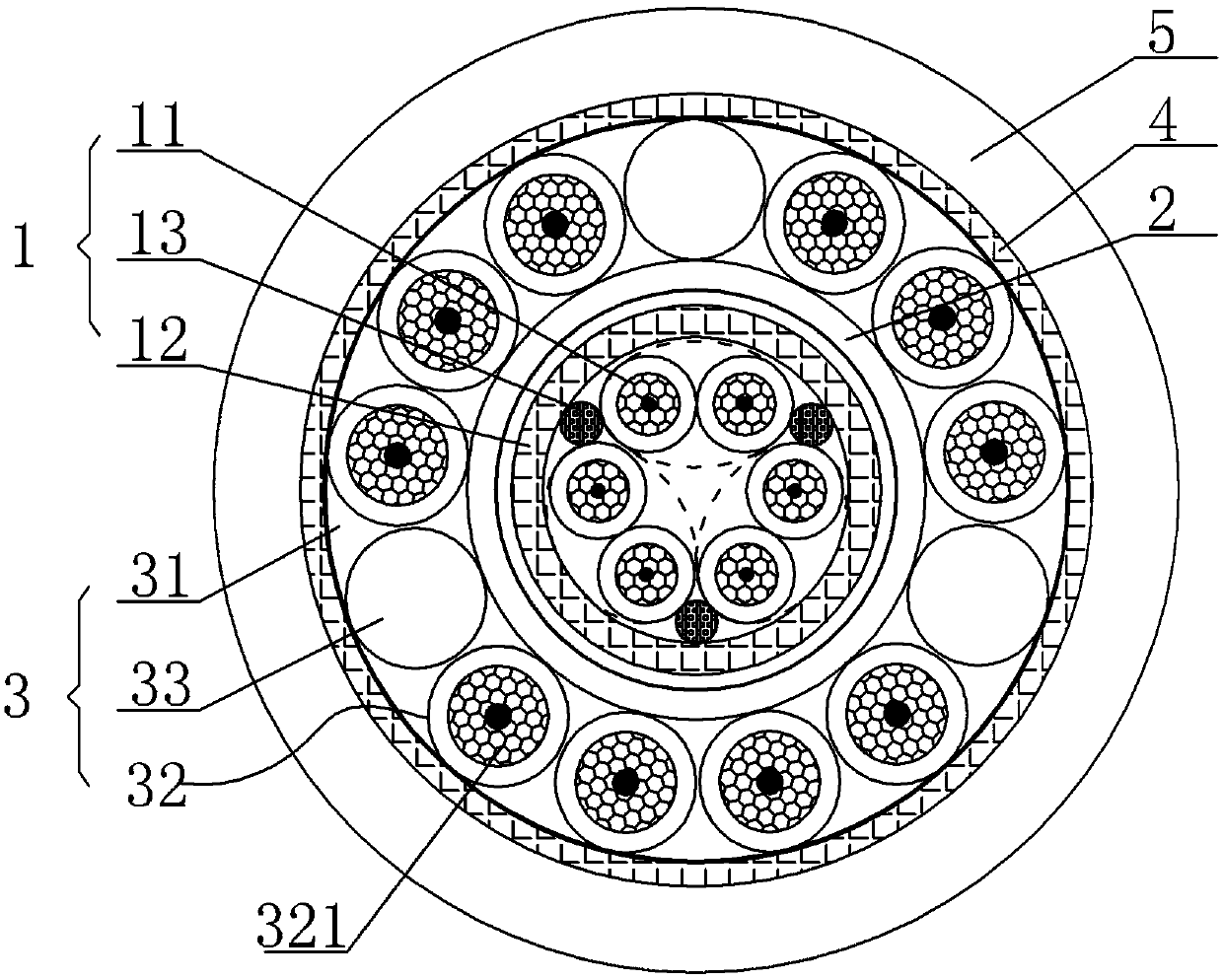

[0048] Specific examples, see figure 1 : six small-diameter first insulated core wires 11 are twisted and covered by the outer wrapping part 12, and the outer wrapping part 12 is combined to form the inner cavity wall and the outer ring surface of the insulating layer of the first insulated core wires 11. There are three evenly distributed Aramid yarn, the outer ring part of the outer wrapping part 12 is covered with the first insulating layer 2, and the inner ring of the annular cavity 31 formed between the outer ring surface of the first insulating layer 2 and the inner ring surface of the braided shielding layer 4 There are stranded nine second insulated core wires 32 and three light-duty filler strips 33, among which three second insulated core wires 32 and one light-duty filler strip 33 form a group of structures, and the three groups of structures are twisted and arranged in ring cloth, braided The outer ring surface of the shielding layer 4 is covered with a sheath laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com