Galvanization pretreatment method of zinc-based alloy

A pre-plating treatment and alloying technology, applied in the field of electroplating, can solve the problems of high wastewater treatment costs, prohibition of using anti-staining salt, strong acidity of industrial wastewater, etc., and achieve good results and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

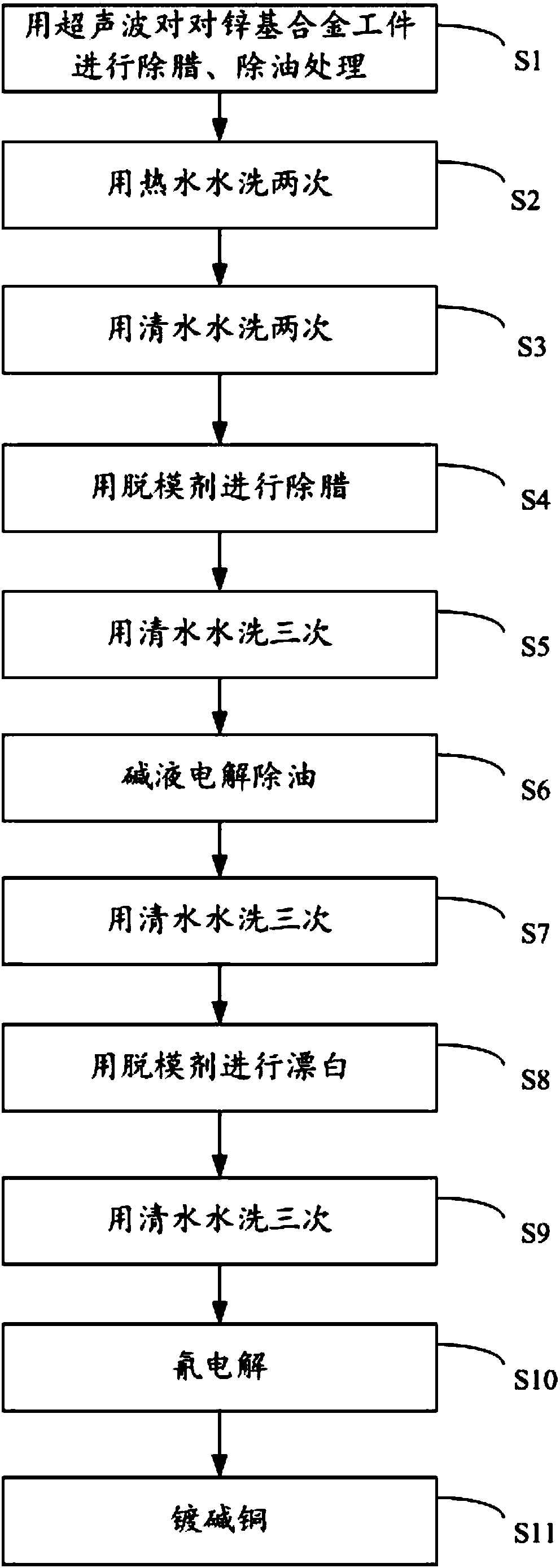

[0013] Such as figure 1 Shown, the present invention discloses a kind of electroplating pretreatment method of zinc-based alloy, comprises the following steps:

[0014] S1: Use ultrasonic waves to remove wax and oil from zinc-based alloy workpieces;

[0015] S2: Put the workpiece into two hot water pools and wash it twice with hot water to prevent the wax removal water on the workpiece from drying out to form an oxide film, resulting in oil on the workpiece after electroplating;

[0016] S3: Wash twice with clean water to strengthen the cleaning of the workpiece, which is cleaned twice through the secondary water tank;

[0017] S4: Use a release agent to remove wax, instead of concentrated sulfuric acid, to treat the wax mold on the surface of the workpiece;

[0018] S5: Wash three times with clean water to further strengthen the cleaning of the workpiece to prevent the acid in the release agent from being brought into the alkaline degreasing tank, which is cleaned three tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com