Control method of one-button discharge of sedimentation tank in polymerization production

A control method and material pouring technology, applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve the problems of difficult to achieve reasonable operation, many errors, frequent operation, etc., to overcome the impact of product quality and safe production. , the effect of improving control accuracy and detection accuracy, and improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

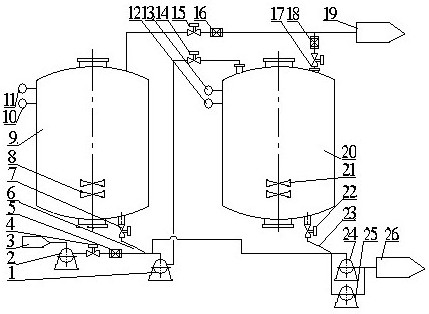

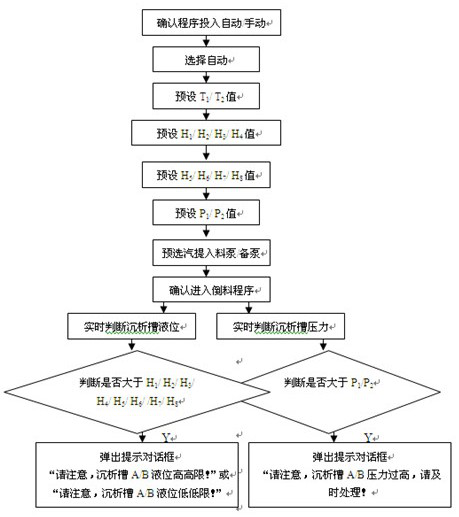

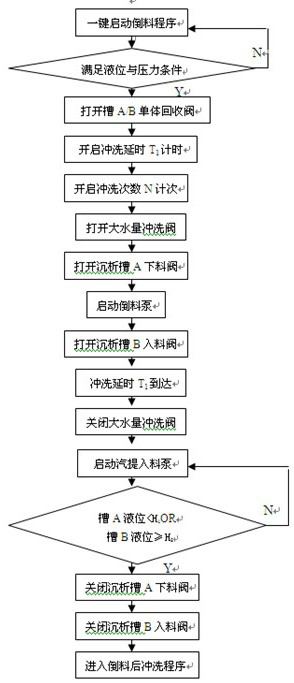

[0026] Refer to attached figure 1 -4, Example 1 of the present invention is a one-key discharge control method for sedimentation tanks in polymerization production. DCS controls the manual operation process of the original sedimentation tanks A / B9 and 20 two tanks: flushing→dumping→rinsing The process and human judgment operation are changed to DCS automatic control to complete.

[0027] The preset flushing times N=2 during the above flushing → discharge → flushing process operation, and the flushing delay is T 1 =200 seconds, flushing pipeline delay T 2 =300 seconds, the liquid level of sedimentation tank A is high and high limit H 1 =100 cm, height limit H 2 =90cm, low limit H 3 =40cm, lower limit H 4 =50 cm, the height limit of the liquid level of the sedimentation tank B is H 5 =100 cm, height limit H 6 =90cm, low limit H 7 =30cm, lower limit H 8 =40cm, sedimentation tank A / B9, 20 pressure P 1 =0.3MPa, P 2 =0.3MPa, preset start, stop, manual, automatic, pause bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com