Modified activated carbon for reducing bioavailability of tetrabromobisphenol A in contaminated soil

A biologically effective, tetrabromobisphenol technology, applied in the restoration of polluted soil, other chemical processes, chemical instruments and methods, etc., can solve secondary pollution, easy to destroy soil ecological function structure, microorganism and phytoremediation cycle Long and other issues, to achieve the effect of expanding the operating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

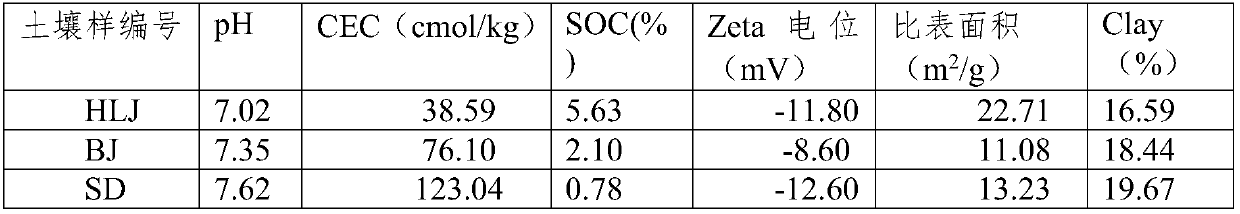

[0012] The modified activated carbon for reducing the bioavailability of tetrabromobisphenol A in polluted soil in the embodiment of the present invention, the preparation of the modified biochar component: the collected corn stalks are broken into flakes with a length less than 1 cm, and placed in an oven Dry it at 105°C for 12h, then place it in a muffle furnace at 400°C for 24h under anaerobic conditions, blow nitrogen into the furnace, take out the burning residue after cooling and grind it thoroughly.

[0013] The biochar obtained above was reacted with 6M HCl at 50°C for 24 hours, the mass volume ratio of biochar to 6M was 1:4, and the supernatant was removed by centrifugation after standing still. Use 2M HCl to wash the residual biochar, remove the supernatant, add 6M HCl and 22M HF mixture in a mass volume ratio of 1:2 to decompose the residual inorganic matter in the biochar, the temperature condition is 60°C, and the reaction After 24 hours, it was washed with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com