Processing system for separating barite from tailings and method of processing system

A processing system and barite technology, applied in solid separation, grain processing, etc., can solve the problems of water separation, inability to solve dust-proof and small particle ore recovery problems, etc., to prevent diffusion, reduce energy consumption, and reduce water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

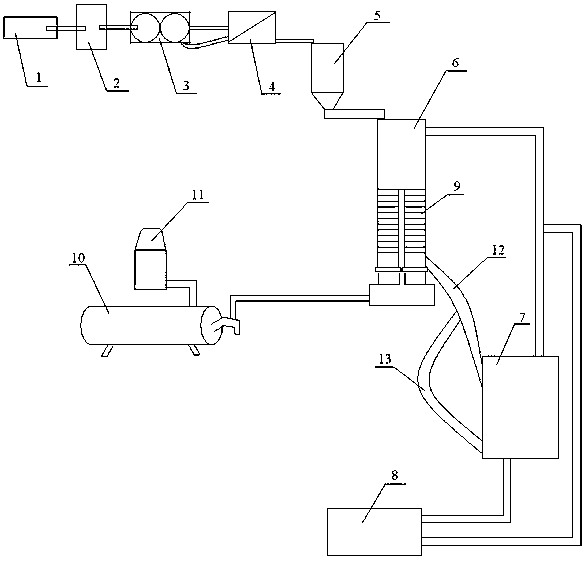

[0035] Such as figure 2 As shown, a processing system for separating barite from tailings, the system includes PE compound pendulum jaw crusher Ⅰ1, PE compound pendulum jaw crusher Ⅱ2, and roller machine 3 connected together by a belt conveyor , Shaker 4.

[0036] The vibrating screen 4 is respectively provided with a discharge port for raw ore particles with a particle size ≥ 3 mm and a discharge port for raw ore particles with a particle size ≥ 3 mm; the discharge port for raw ore particles with a particle size ≥ 3 mm is connected to the roller machine 3 through the conveyor belt I; The raw ore particle outlet with a particle size of <3mm is connected to the silo 5 through the conveyor belt II; the bottom of the silo 5 is provided with a feeder, and the end of the feeder is connected with a jig 6; There is a sprinkler, one side of which is connected to a sedimentation tank 7 and a purification tank 8 respectively through pipelines, and two water separation screens 9 with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com