Wood composite material and preparation method thereof

A composite material and wood technology, which is applied in the field of wood composite materials and its preparation, can solve the problems of high production cost, achieve the effects of low weight gain, simple and easy process flow, and poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

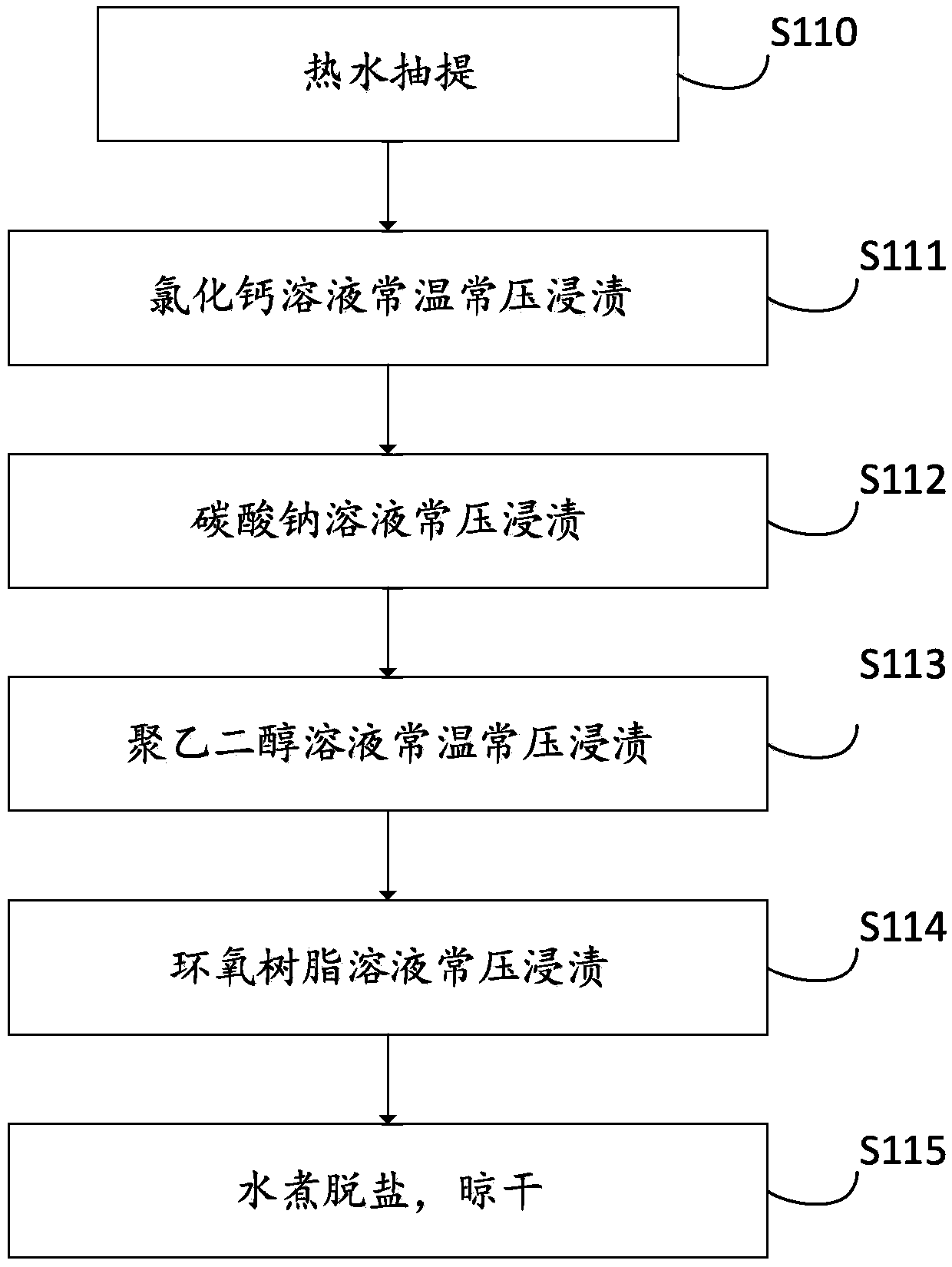

[0041] see figure 1 As shown, the preparation method provided by Embodiment 1 of the present invention includes steps:

[0042] Step S110, performing hot water extraction treatment on the wooden veneer;

[0043] Step S111, placing the wooden veneer treated in step S110 into a calcium chloride solution for magnetic stirring, and then adding a coupling agent and impregnating it under normal temperature and pressure;

[0044] Step S112, immersing the wood veneer treated in step S111 in a sodium carbonate solution under normal pressure;

[0045] Step S113, placing the wooden veneer treated in step S112 into a polyethylene glycol solution and impregnating it under normal temperature and pressure;

[0046] Step S114, placing the wooden veneer treated in step S113 into an epoxy resin solution and impregnating it under normal pressure;

[0047] In step S115, the wooden veneer treated in step S114 is boiled and desalinated, and then dried.

[0048] In this embodiment, a 1mm thick l...

Embodiment 2

[0058] In Example 2 of the present invention, firstly, the larch veneer with a thickness of about 1.5 mm is subjected to hot water extraction treatment, the experimental temperature is 50° C., and the extraction time is 30 minutes. Specifically, put a larch veneer about 1.5 mm thick in a container filled with distilled water, cover it and place it in a hot water bath at a heating rate of 2 °C / min until the test temperature reaches 50 °C, then keep it warm for 30 min. Dry the sample after taking it out.

[0059] Prepare calcium chloride solution, concentration is 0.3mol / l, under the condition of room temperature, stir 2H with the speed of 500R / MIN with magnetic stirrer. Then add a small amount of coupling agent 3-aminopropyltriethoxysilane, the amount of coupling agent is 0.25g / L, soak at normal temperature and pressure for 24H, take out the test piece and wrap it for 24H. The material selected for wrapping should be light and soft material that avoids chemical reaction with t...

Embodiment 3

[0065] Embodiment 3 of the present invention is still described by taking larch veneer as an example of a log test piece. The log species that can be used in the present invention are not limited to larch, but can also be other types, such as willow, paulownia, fast-growing poplar and the like.

[0066] The thickness of the original wood veneer can be 0.8mm-2.5mm (millimeters), and those skilled in the art can make specific adjustments according to the technical concept of the technical solution of the present invention and actual needs, and the present invention does not limit them one by one.

[0067] First, put the larch veneer in a container filled with distilled water, cover it and put it in a hot water bath, the heating rate is 2°C / min, until the test temperature reaches 70°C, keep it warm for 30min, take out the sample and dry it .

[0068] Prepare a calcium chloride solution with a concentration of 0.4mol / 1. At room temperature, stir with a magnetic stirrer at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com