Hierarchical pore SAPO-34 molecular sieve synthesis method

A synthesis method and molecular sieve technology are applied in the directions of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of increased cost, cumbersome synthesis steps, unfavorable industrialized production, etc., and can improve the service life and reduce the cost of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

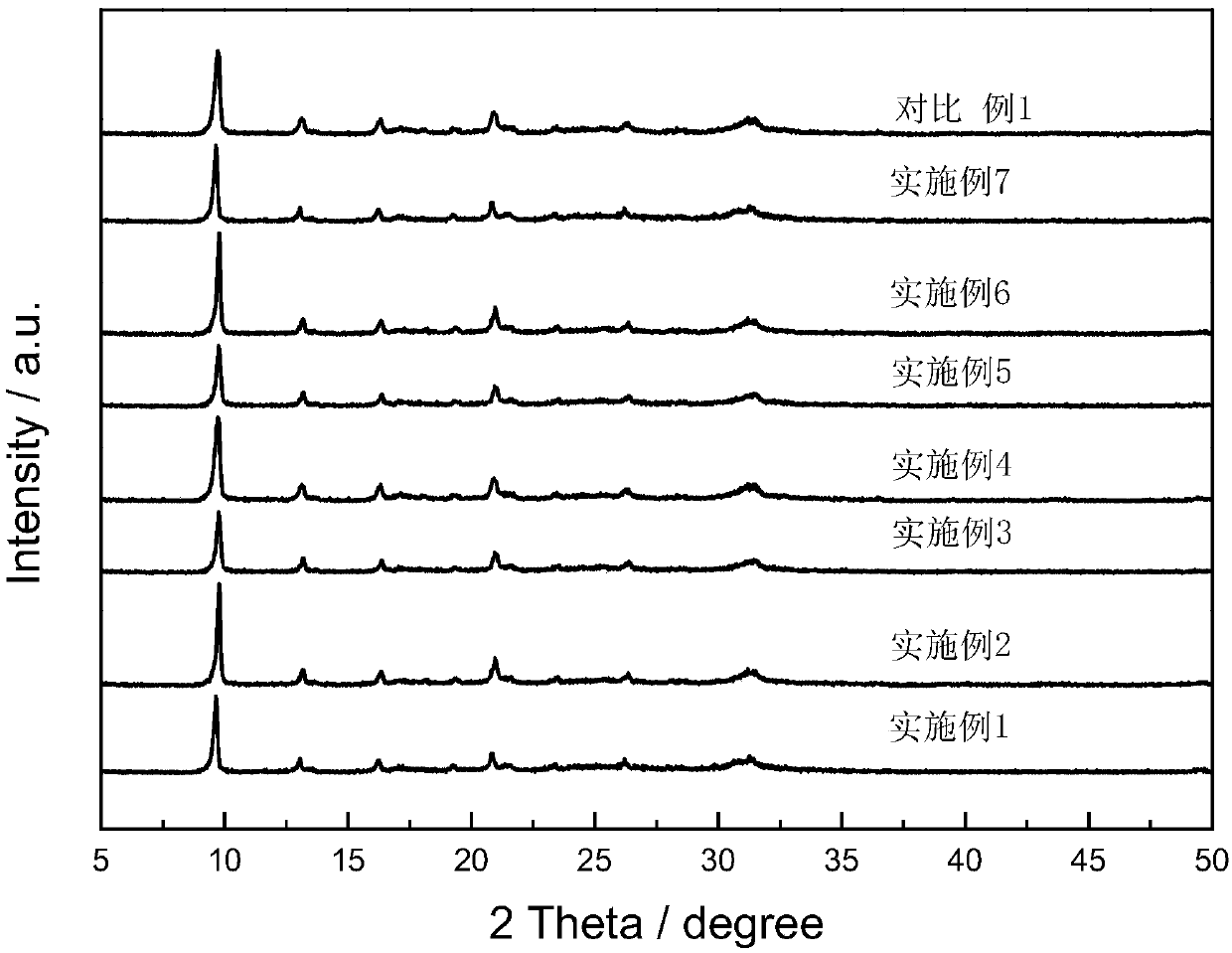

[0035] At room temperature, add water, water glass, aluminum isopropoxide, phosphoric acid and triethylamine to the beaker in turn, stir and mix thoroughly to obtain the initial gel mixture of SAPO-34 molecular sieve, the molar ratio of each component of the mixture is : 1.0Al 2 o 3 : 0.1 SiO 2 : 0.8P 2 o 5 : 1.5 Triethylamine: 10H 2 O. After the stirring, put the above-mentioned gel mixture into a stainless steel reactor, then put the reactor into a dynamic oven, raise the temperature to 160°C, and crystallize at a constant temperature for 60 hours. After the crystallization is completed, filter, wash, and dry to obtain a solid product, that is, the original powder of SAPO-34 molecular sieve. The original SAPO-34 molecular sieve powder was calcined in air at 650°C for 2 hours to remove the template agent contained in the original powder, and a white SAPO-34 molecular sieve with hierarchical pores was obtained. XRD spectrum as figure 1 As shown, the SEM photos are as ...

Embodiment 2

[0037] At room temperature, add water, sodium silicate, aluminum sol, ammonium phosphate and diethylamine to the beaker in turn, stir to make it fully mixed, and obtain the SAPO-34 molecular sieve initial gel mixture, and the molar ratio of each component of the mixture is : 1.0Al 2 o 3 : 0.6SiO2 2 : 1.2P 2 o 5 : 2.5 diethylamine: 50H 2 O. After the stirring, put the above gel mixture into a stainless steel reactor, then put the reactor into a dynamic oven, raise the temperature to 180°C, and crystallize at constant temperature for 8 hours. After the crystallization is completed, filter, wash, and dry to obtain a solid product, that is, the original powder of SAPO-34 molecular sieve. The original SAPO-34 molecular sieve powder was calcined in air at 500° C. for 10 h to remove the template agent contained in the original powder, and a white SAPO-34 molecular sieve with hierarchical pores was obtained. XRD spectrum as figure 1 As shown, the SEM photos are as image 3 sho...

Embodiment 3

[0039] At room temperature, add water, silica sol, pseudo-boehmite, phosphoric acid and triethylamine to the beaker in turn, stir and mix thoroughly to obtain the SAPO-34 molecular sieve initial gel mixture. The molar ratio of each component of the mixture is For: 1.0Al 2 o 3 : 0.44SiO2 2 : 1.1P 2 o 5 : 2.25 Triethylamine: 36H 2O. After the stirring, put the above gel mixture into a stainless steel reaction kettle, then put the reaction kettle into a dynamic oven, raise the temperature to 165° C., and crystallize at a constant temperature for 33 hours. After the crystallization is completed, filter, wash, and dry to obtain a solid product, that is, the original powder of SAPO-34 molecular sieve. The original SAPO-34 molecular sieve powder was calcined in air at 600°C for 6 hours to remove the template agent contained in the original powder, and a white SAPO-34 molecular sieve with hierarchical pores was obtained. XRD spectrum as figure 1 As shown, the SEM photos are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com