Preparation method of biomass based lightweight window profile

A biomass and window technology, applied in window/door frame, leaf frame, etc., can solve the problems of poor combination of lignin component and polyurethane, and inability to replace lignin component, so as to achieve strong screw holding force and light weight , the effect of high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

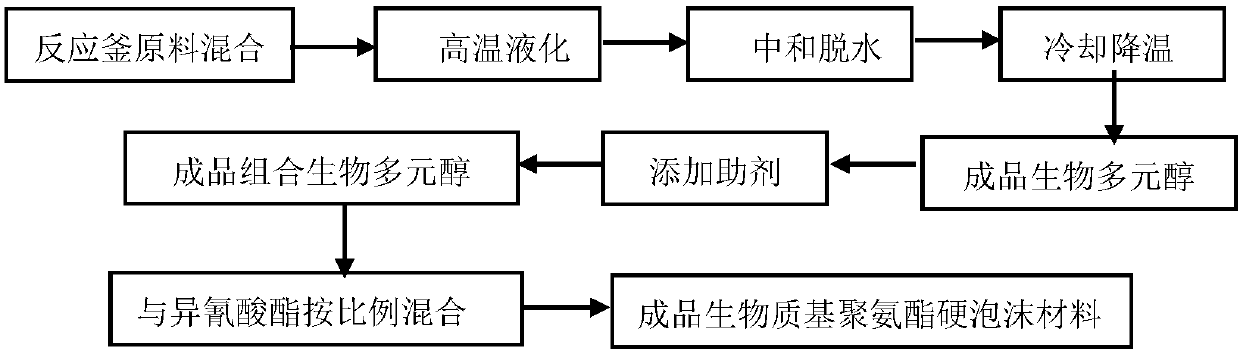

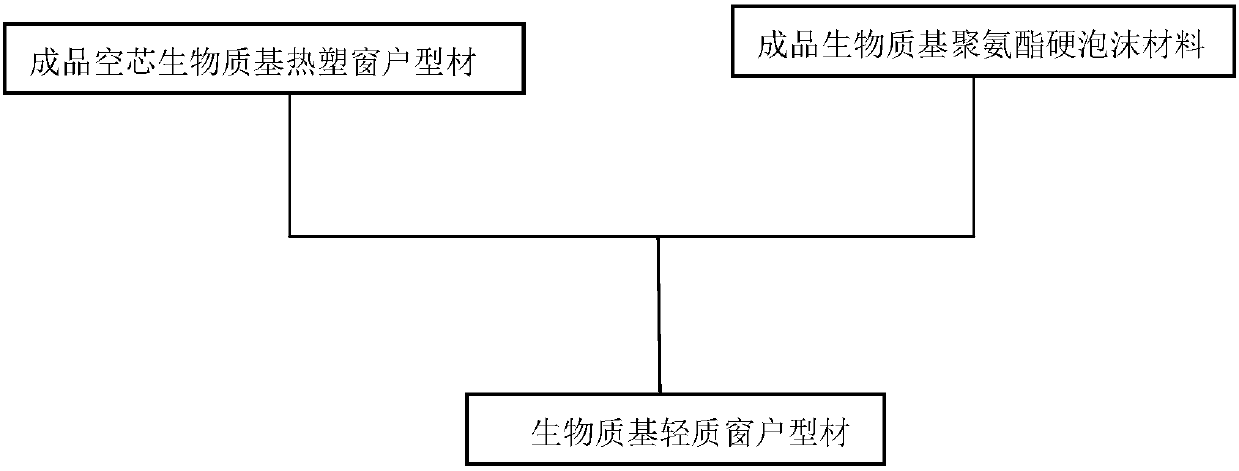

[0036] This embodiment provides a method for preparing a biomass-based lightweight window profile. The steps include: preparing a hollow-core biomass-based thermoplastic window profile, preparing a biomass-based polyurethane rigid foam material, and preparing a biomass-based lightweight window profile, among them,

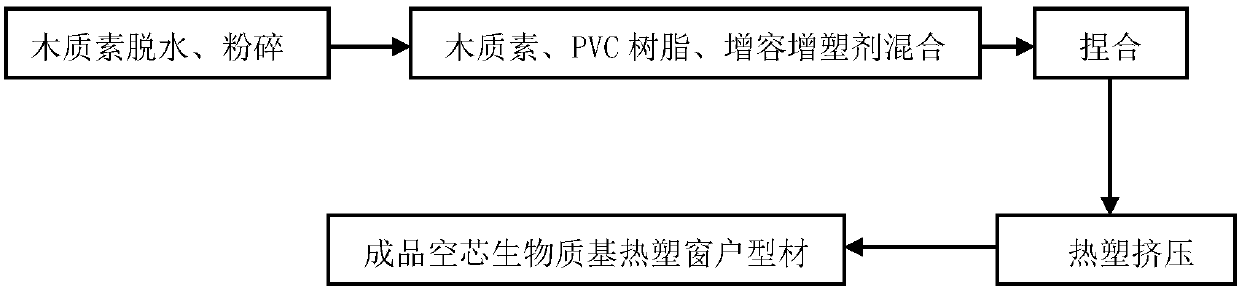

[0037] The steps of preparing hollow-core biomass-based thermoplastic window profiles include:

[0038] 1) Lignin dehydration:

[0039] Put the lignin in a vacuum reaction kettle, turn on the vacuum system, control the vacuum in the kettle to 0.06MPa, first raise the temperature in the kettle to 75°C for 10 minutes, then increase the temperature in the kettle to 110°C for 12 minutes and then cool down Discharge at 35°C so that the moisture content of lignin is below 5%;

[0040] 2) Put the lignin into a fine pulverizer for pulverization, and select 400 mesh lignin after pulverization;

[0041] 3) Select 5 parts of compatibilizing plasticizer according to mass parts and put...

Embodiment 2

[0056] This embodiment provides a method for preparing a biomass-based lightweight window profile. The steps include: preparing a hollow-core biomass-based thermoplastic window profile, preparing a biomass-based polyurethane rigid foam material, and preparing a biomass-based lightweight window profile, among them,

[0057] The steps of preparing hollow-core biomass-based thermoplastic window profiles include:

[0058] 1) Dehydration of lignin;

[0059] Put the lignin in a vacuum reaction kettle, turn on the vacuum system, control the vacuum in the kettle to 0.09MPa, first raise the temperature in the kettle to 90°C for 15 minutes, then increase the temperature in the kettle to 120°C for 20 minutes and then cool down Discharge at 45°C so that the moisture content of lignin is below 5%;

[0060] 2) Put the lignin into a fine pulverizer for pulverization, and select 600 mesh lignin after pulverization;

[0061] 3) Select 10 parts of compatibilizing plasticizer according to the number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus of elasticity | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com