Combustor for combusting biomass particle fuels

A technology of biomass particles and burners, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of energy waste, environmental pollution, high heating costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

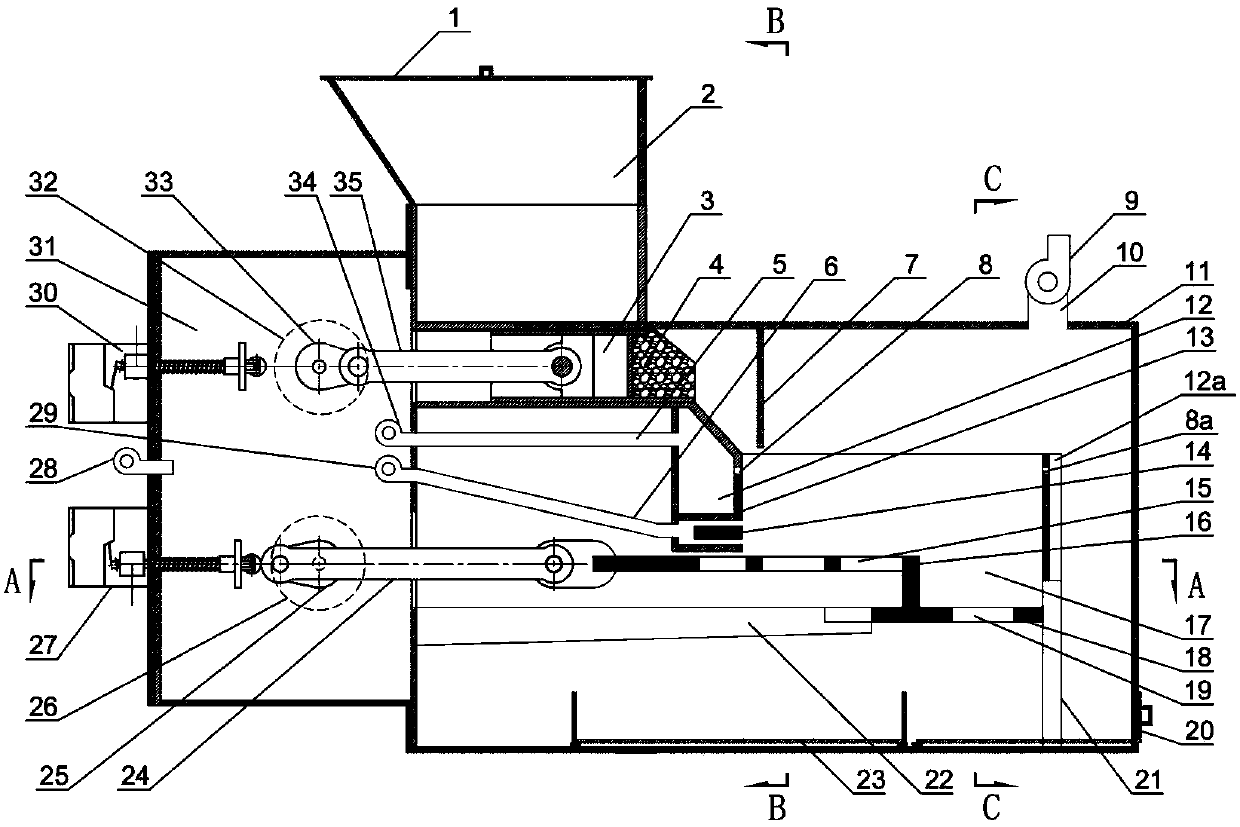

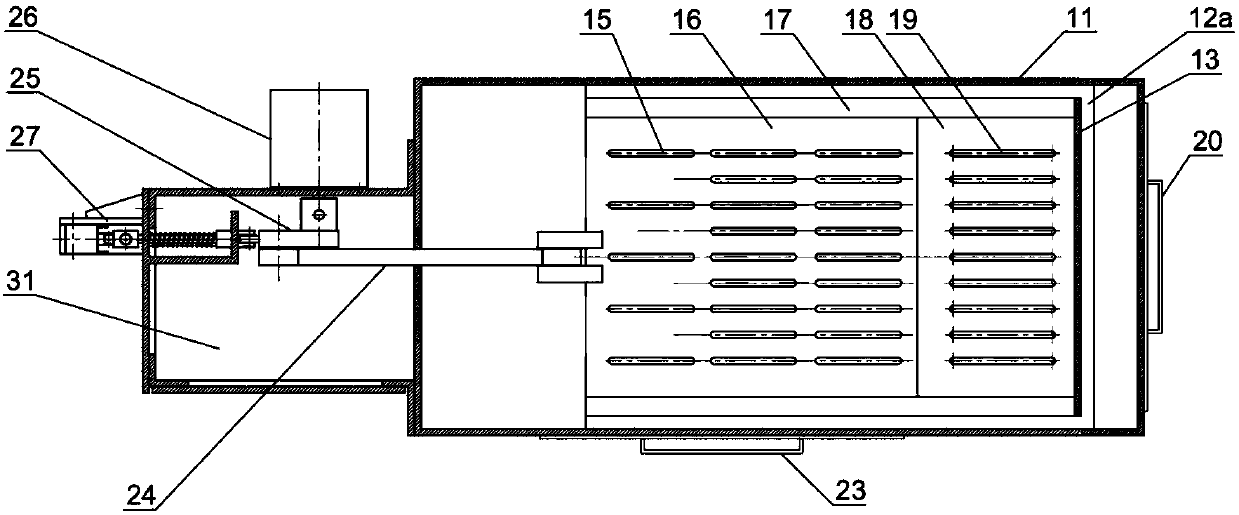

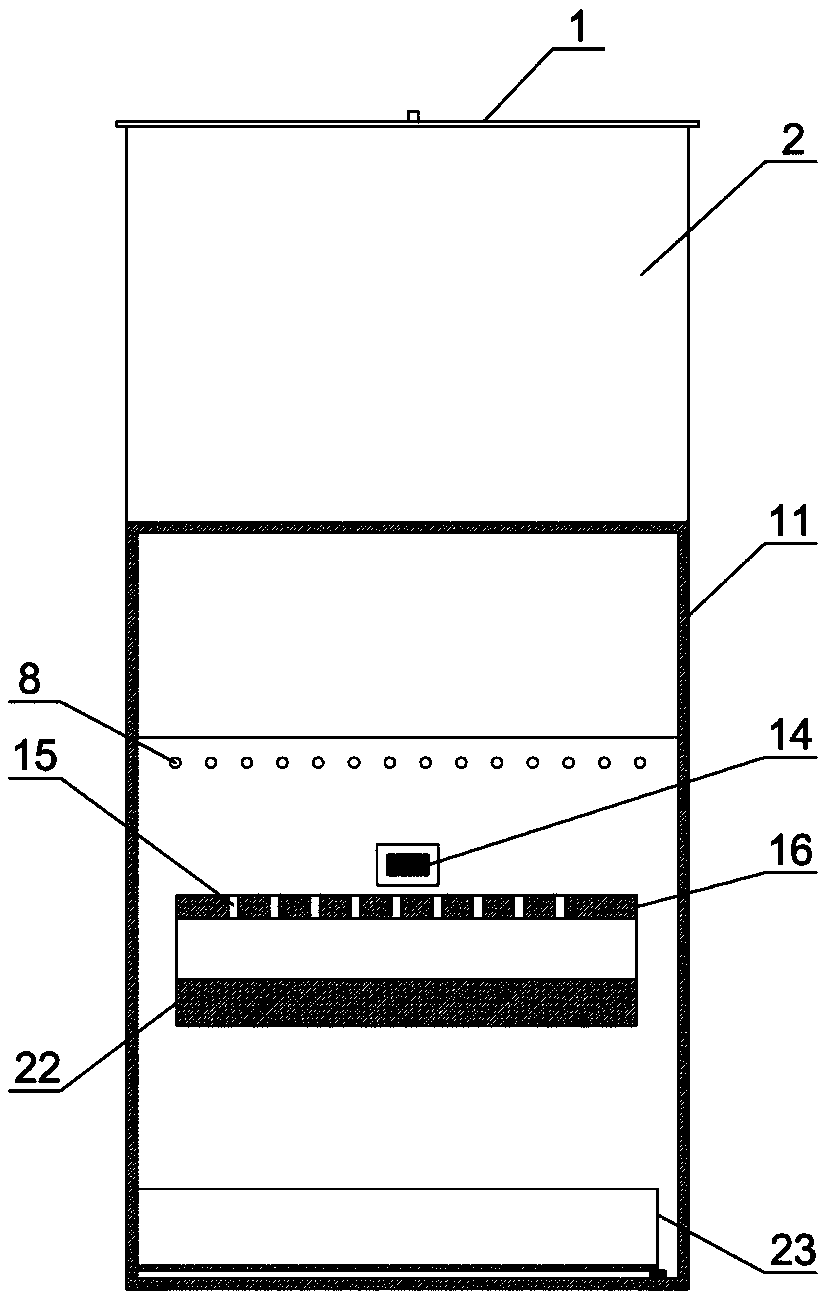

[0017] The working principle and specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] figure 1 A schematic structural view of a burner for burning biomass pellet fuel provided by the present invention, figure 2 for figure 1 The A-A section diagram of image 3 for figure 1 The B-B section diagram, Figure 4 for figure 1 The C-C section diagram.

[0019] The burner of this embodiment includes a material box 2, a combustion chamber 11 located below the material box 2, an equipment box 31 fixed and communicated with the rear end side wall of the combustion chamber 11, a feeding system, a combustion system, an air supply system and an ignition system ;in,

[0020] The top of the combustion chamber 11 near the front end is provided with a chimney connection port 10 and a smoke exhaust fan 9, and the middle part and the end of the inner bottom of the combustion chamber 11 are respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com