Vacuum thermal isolation tank

A vacuum insulation and vacuum tank technology, applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve problems such as drug deterioration, human side effects, accelerated chemical reactions, etc., to improve safety performance, reduce production costs, The effect of preventing chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

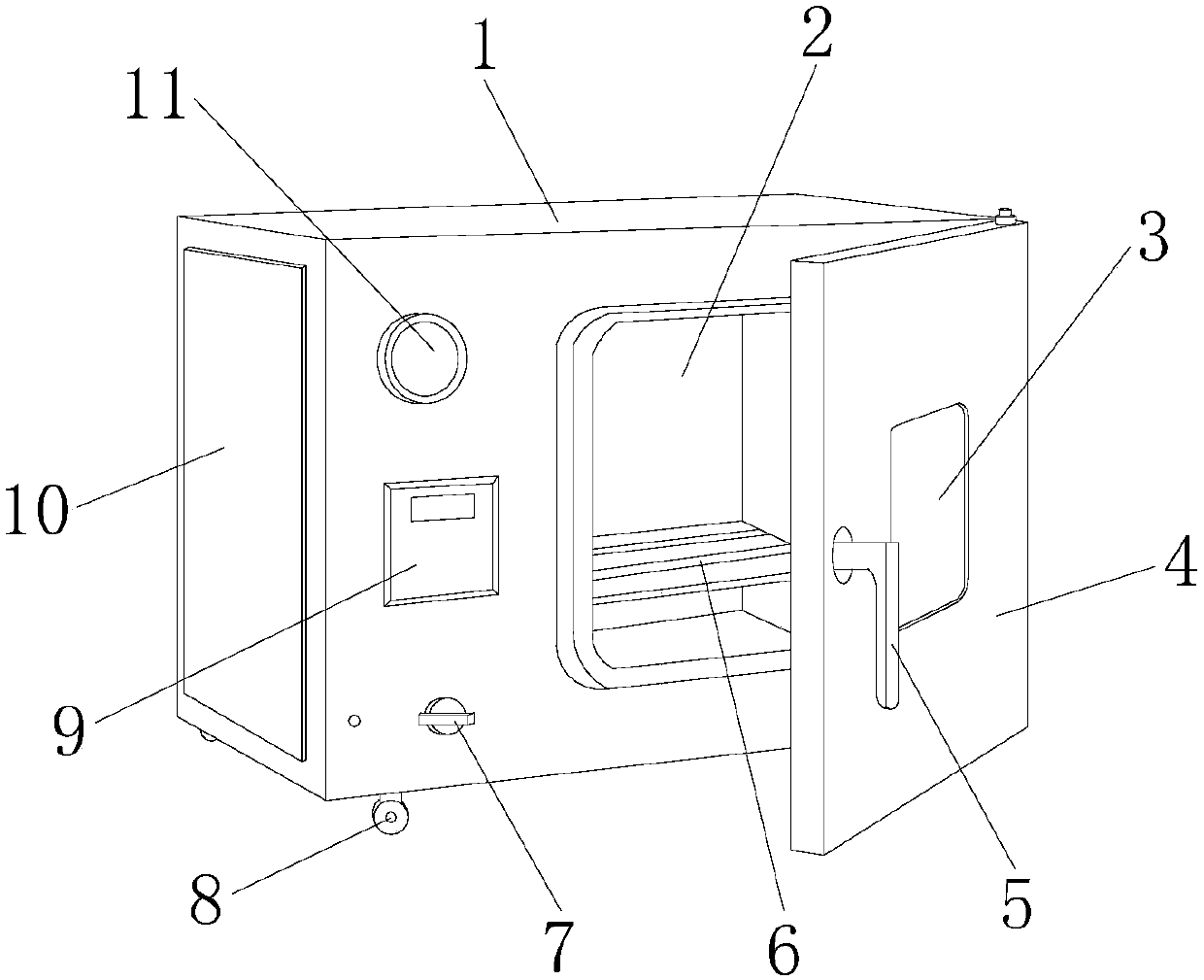

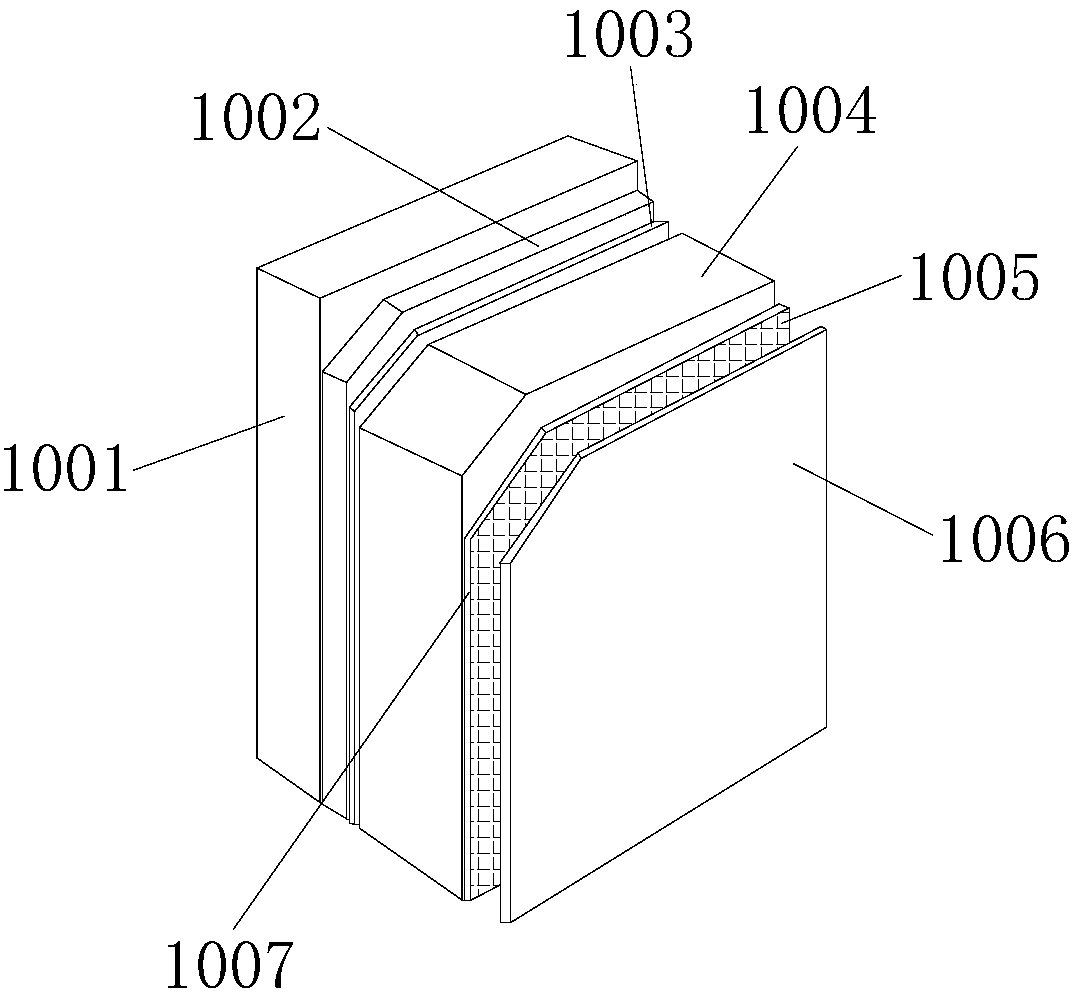

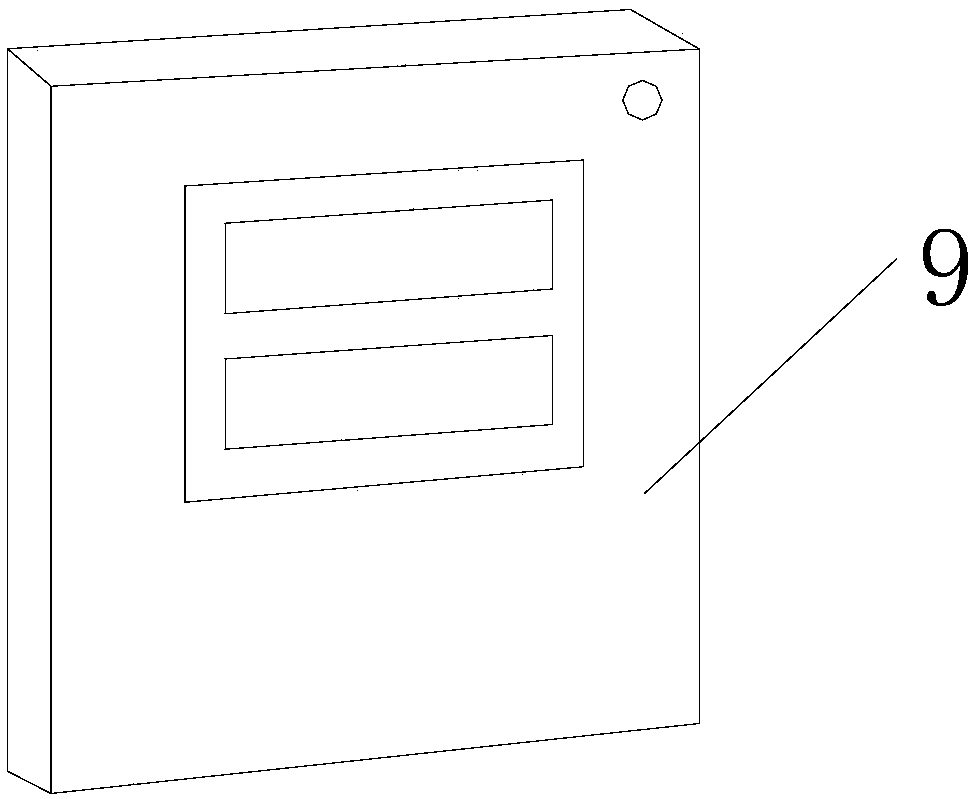

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a vacuum insulation box, the structure of which includes a box body 1, a vacuum tank 2, an observation window 3, a box door 4, a handle 5, a shelf 6, a switch knob 7, and a universal wheel 8 , display 9, heat shield 10, barometer 11, the box body 1 is a cuboid structure, and the four corners of the lower surface of the box body 1 are respectively connected with the top of the universal wheel 8 by threaded forward rotation, and are in the same On the horizontal line, it is distributed in a rectangular shape. The universal wheel 8 is a cylindrical structure, and there are four in total. The right side of the front surface of the box body 1 is connected with the righ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap