Generation method of LED ecological light source capable of satisfying plant growth and human eye requirement simultaneously

A LED light source and plant growth technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as not being able to meet the normal growth of indoor plants, and achieve the effects of enhancing high definition, enhancing visual comfort, and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

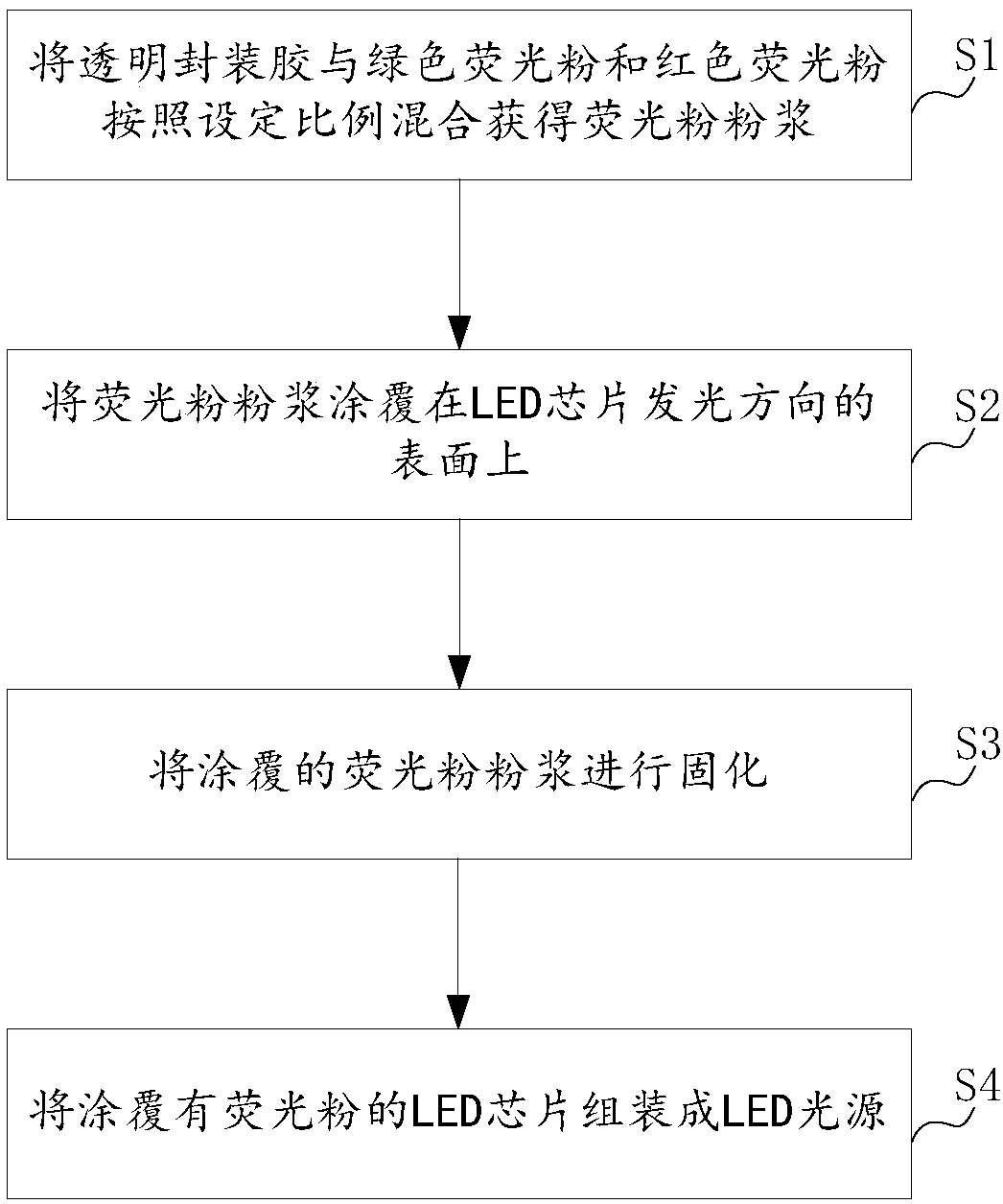

[0048] see image 3 , the invention discloses a method for generating an LED ecological light source that can simultaneously meet the needs of plant growth and human eyes, comprising the following steps:

[0049] Step S1, mixing the transparent encapsulant with the green phosphor and the red phosphor according to a set ratio to obtain a phosphor paste;

[0050] Step S2, coating the phosphor powder paste on the surface of the LED chip in the direction of light emission:

[0051] Step S3, curing the coated phosphor paste;

[0052] Step S4, assembling the LED chip coated with phosphor powder into an LED light source.

[0053] In step S1, the colloid may be one or more combinations of silica gel and epoxy resin.

[0054] In the LED light source, the green fluorescent powder used has a wider spectral component with higher human eye sensitivity, which is convenient for the clarity of human eye observation and visual comfort.

[0055] In the LED light source, the red fluorescent ...

Embodiment 1

[0063] Weigh 0.32g of fluorescent powder (of which, 0.02g of 530nm fluorescent powder, 0.02g of 630nm fluorescent powder, and 0.28g of 660nm fluorescent powder), 1.7g of powder mixing glue (LED organic packaging silica gel, A glue: B glue = 5:1) and Mix the two evenly, vacuumize to remove air bubbles to obtain phosphor powder slurry;

[0064] Apply the phosphor powder slurry on the surface of the blue LED chip with a peak wavelength of 455nm by dispensing method, and put it in a drying oven to heat and fix it. The curing conditions are: 80°C (1h), then 150°C (2h);

[0065] Naturally cooled to room temperature, using a 0.2m integrating sphere to test the correlated color temperature (CCT), color rendering index (Ra) and the ratio of red light (600-700nm) to blue light (400-500nm) in the spectral components (R / B, luminous flux color ratio);

[0066] Finally, one or more LEDs are used to assemble an LED lamp.

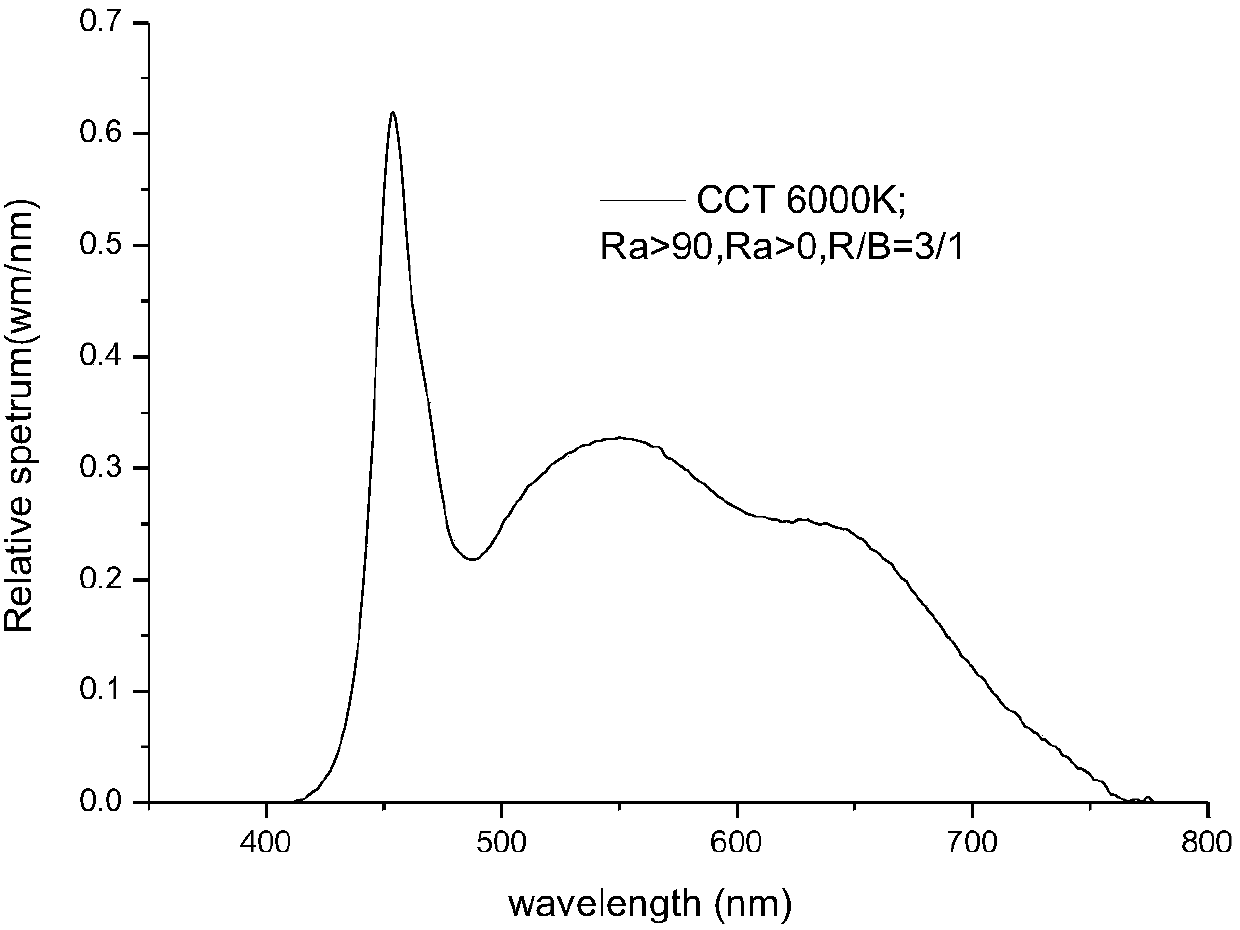

[0067] figure 1 It is the spectrum diagram of an ecological light ...

Embodiment 2

[0069] Weigh 0.32g of fluorescent powder (of which, 0.02g of 530nm fluorescent powder, 0.02g of 630nm fluorescent powder, and 0.28g of 660nm fluorescent powder), 1.7g of powder mixing glue (LED organic packaging silica gel, A glue: B glue = 5:1) and Mix the two evenly, vacuumize to remove air bubbles to obtain phosphor powder slurry;

[0070] Apply the phosphor powder slurry on the surface of the blue LED chip with a peak wavelength of 445nm by dispensing method, and put it in a drying oven to heat and cure. The curing conditions are: 80°C (1h), then 150°C (2h);

[0071] Naturally cooled to room temperature, use a 0.2m integrating sphere to test the correlated color temperature (CCT), color rendering index (Ra), red saturation value R9 and red light (600-700nm) and blue light (400nm) in the spectral components of the cured LED light source ~500nm) ratio (R / B, luminous flux color ratio);

[0072] Finally, one or more LEDs are used to assemble an LED lamp.

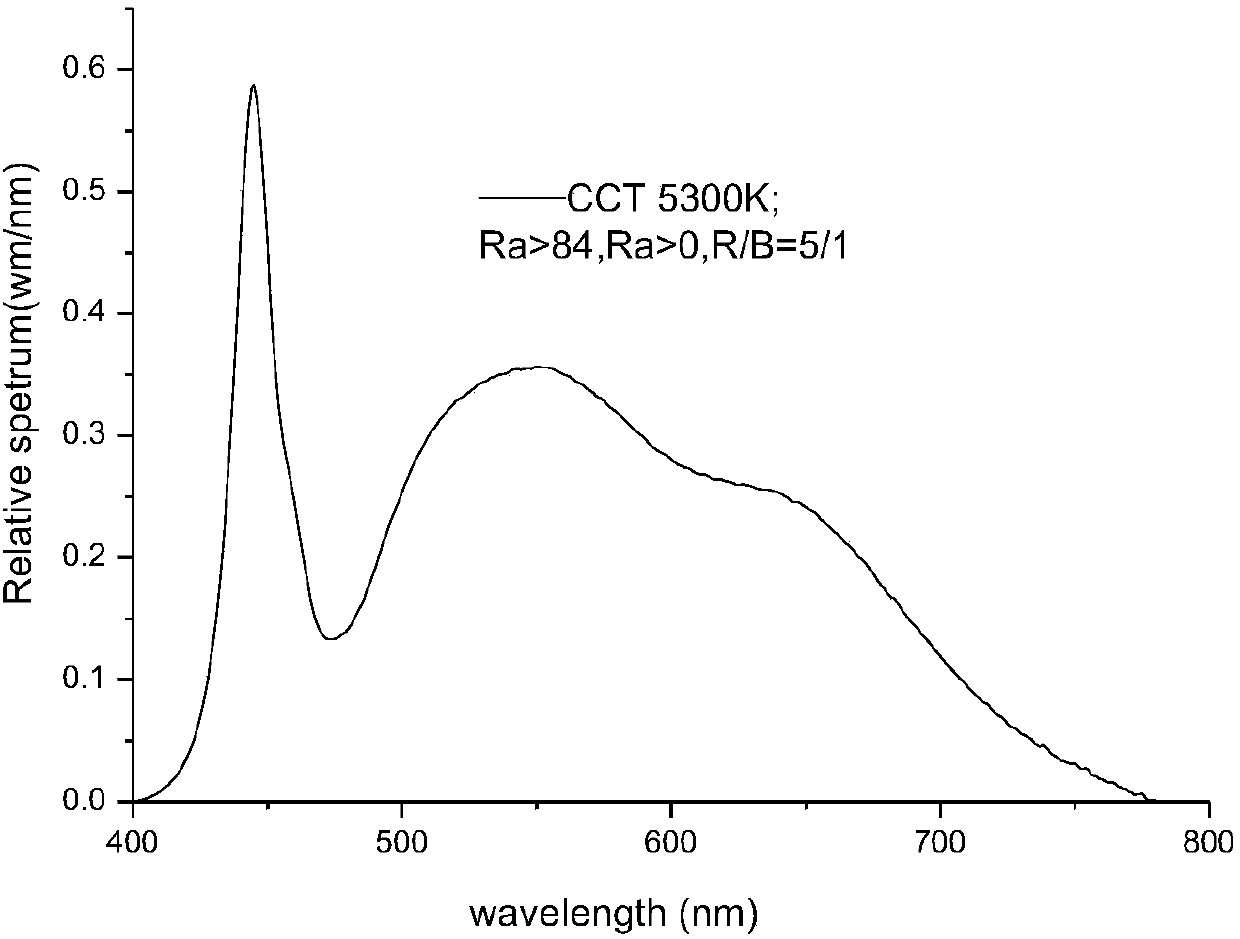

[0073] figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com