Artificial forest collecting operation machinery

A technology of operating machinery and locomotives, applied in forestry, agriculture, applications, etc., can solve problems such as low efficiency, slow development speed, immature technology, etc., and achieve the effect of saving space, convenient transportation, and simple and accurate measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

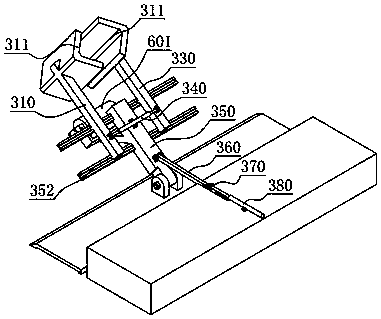

[0055] Figure 4-6 And in 15-16, only represent its trunk 900 parts to the felled trees, omitting branches and leaves.

[0056] 1. Structural features:

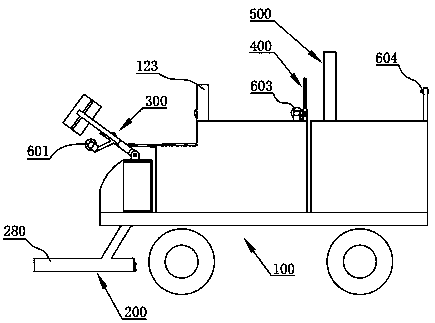

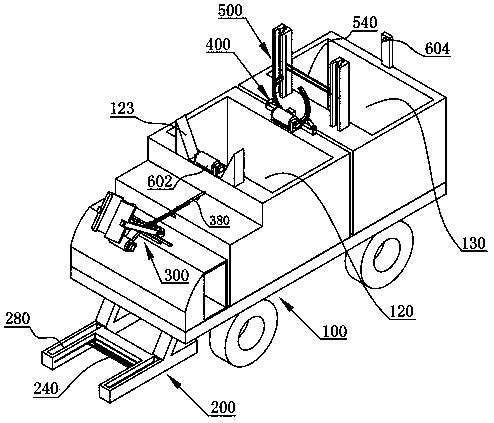

[0057] Figure 1 to Figure 8 As shown in a kind of artificial forest collection operation machine, the work locomotive 100 is provided with cab 110, branches and leaves collection box 120 and trunk collection box 130 successively from front to back. As an improvement: the work locomotive 100 is also provided with logging device 200, Holding mechanism 300, pruning equipment 400, saw segment equipment 500 and driving guide wheel group, the cover plate of the cab 110 is provided with a rotating rod hole seat 111, and the cover plate of the branch and leaf collection box 120 is provided with a turning slide Groove 121 and four hydraulic fixing screw holes 129, the rotating rod hole seat 111 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com