Numerically-controlled groove cutting machine capable of automatically delivering materials and carrying out detection

A CNC slot milling machine and automatic detection technology, applied in the direction of milling machine equipment, milling machine equipment details, measuring/indicating equipment, etc., can solve the problems of using more equipment, low slot milling efficiency, easy jamming and noise, etc., to achieve easy maintenance, Simple structure, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

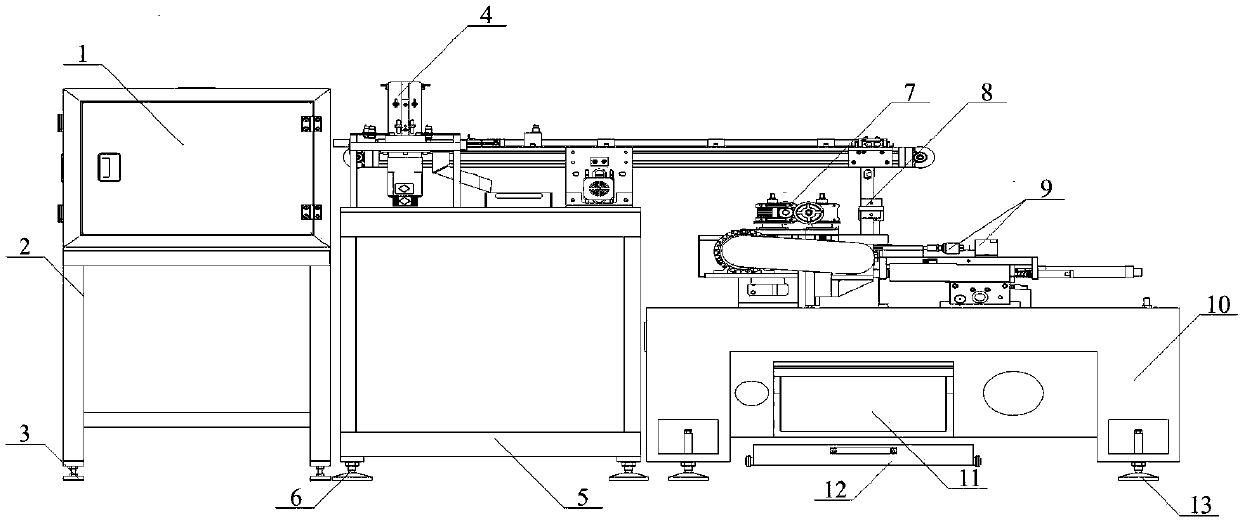

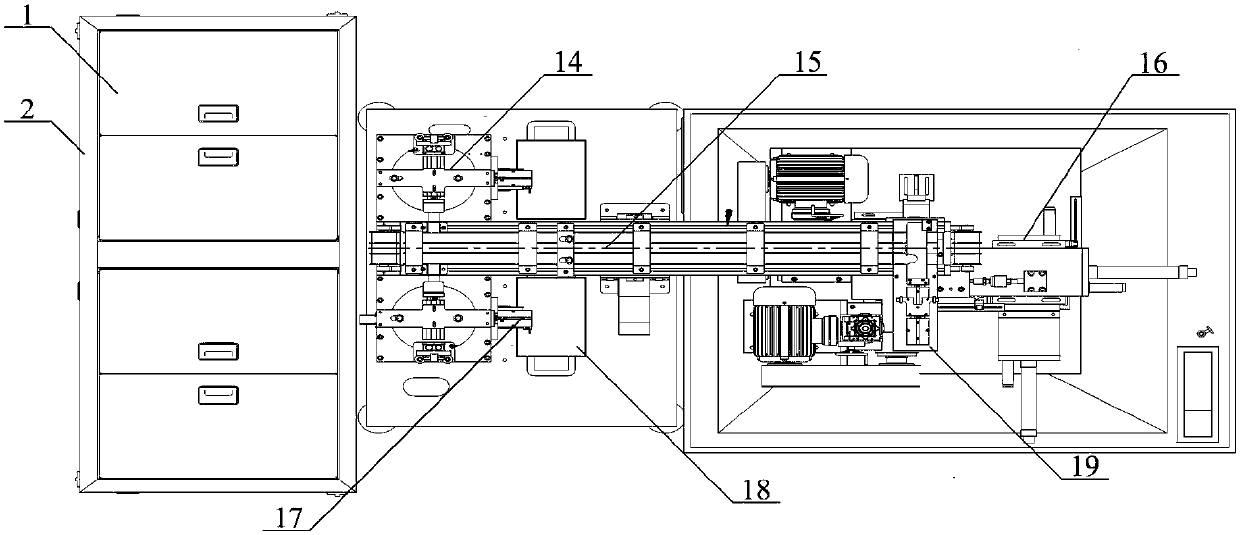

[0033] as attached figure 1 to attach figure 2 shown

[0034] The invention provides a numerically controlled groove milling machine capable of automatic material conveying and automatic detection, which includes a double vibrating plate feeding machine and a soundproof cover 1, a support frame 2, a foot seat 3, a double-station workpiece inner hole through-gauge detection mechanism 4, Electrical cabinet 5, adjustable base 6, milling power head with lifting adjustment 7, workpiece feeding tube 8, workpiece clamping mechanism 9, machine base 10, feeding port 11, copper chip box 12, lifting base 13, double Station servo turntable mechanism 14, conveyor belt feeder 15, workpiece hydraulic cross-feed slide table 16, double-station waste material blanking mechanism 17, waste box 18 and double material channel selection blanking mechanism 19, on the double vibrating plate The feeder and the soundproof cover 1 bolts are installed on the upper part of the support frame 2; the feet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com