Welding method of three-layer dual-face stainless steel composite board

A welding method and stainless steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing welding efficiency, high welding cost, low heat input, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

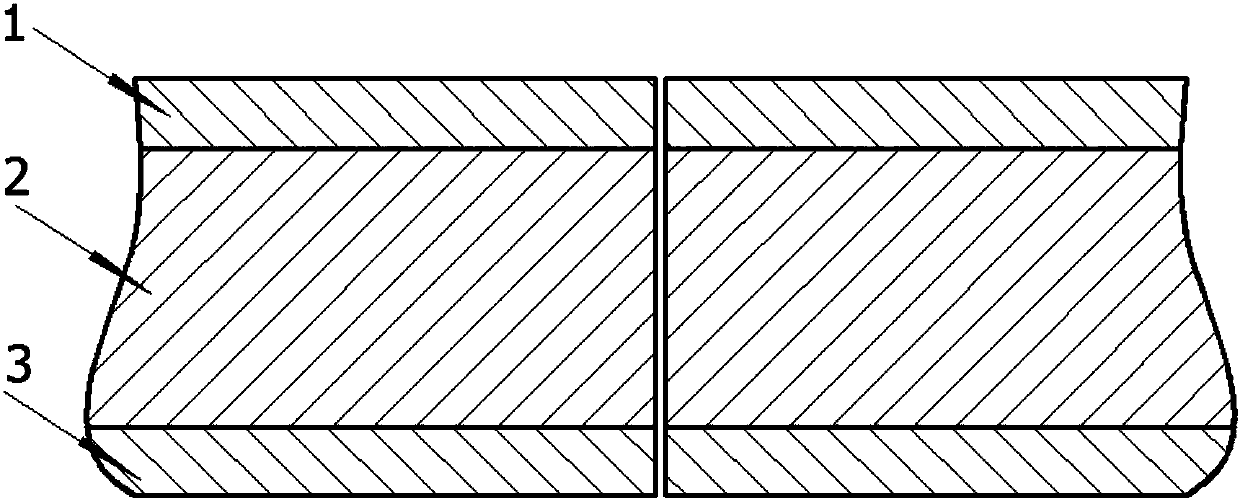

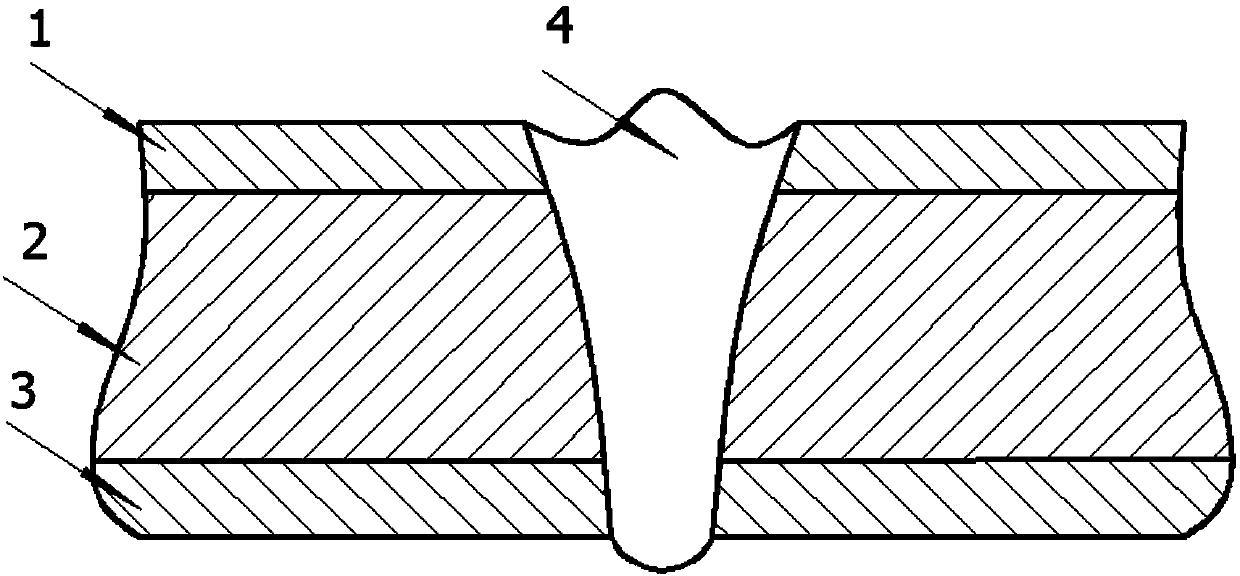

[0015] Example: 304+Q235B+304 three-layer double-sided stainless steel composite plate butt welding

[0016] Q235B is the base layer with a thickness of 8mm, and 304 is a double-sided stainless steel clad layer with a thickness of 2mm. The following welding scheme is adopted for the three-layer double-sided stainless steel clad plate:

[0017] Before welding, the bimetal composite board is machined into a flush end face, and the oxides on the base layer and the clad layer surface of the three-layer double-sided stainless steel composite board to be welded are removed by grinding. Assemble the two butt welding test plates according to type I, the assembly gap is less than 1mm, use stainless steel welding consumables to weld the two ends of the double-sided stainless steel composite plate, keep the welding test plates in the same horizontal plane, and weld the same welding at both ends of the weld bead. The material is the same thickness as the arc strike plate. The keyhole TI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com