Compound efficient hardening-accelerating and water-reducing admixture used for concrete

An early-strength water-reducing agent and concrete technology, which is applied in the field of concrete additives, can solve the problems of increasing the cost of water-reducing agents, excessive concrete slump, and weakening water-reducing performance, so as to prevent agglomeration, save manpower, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

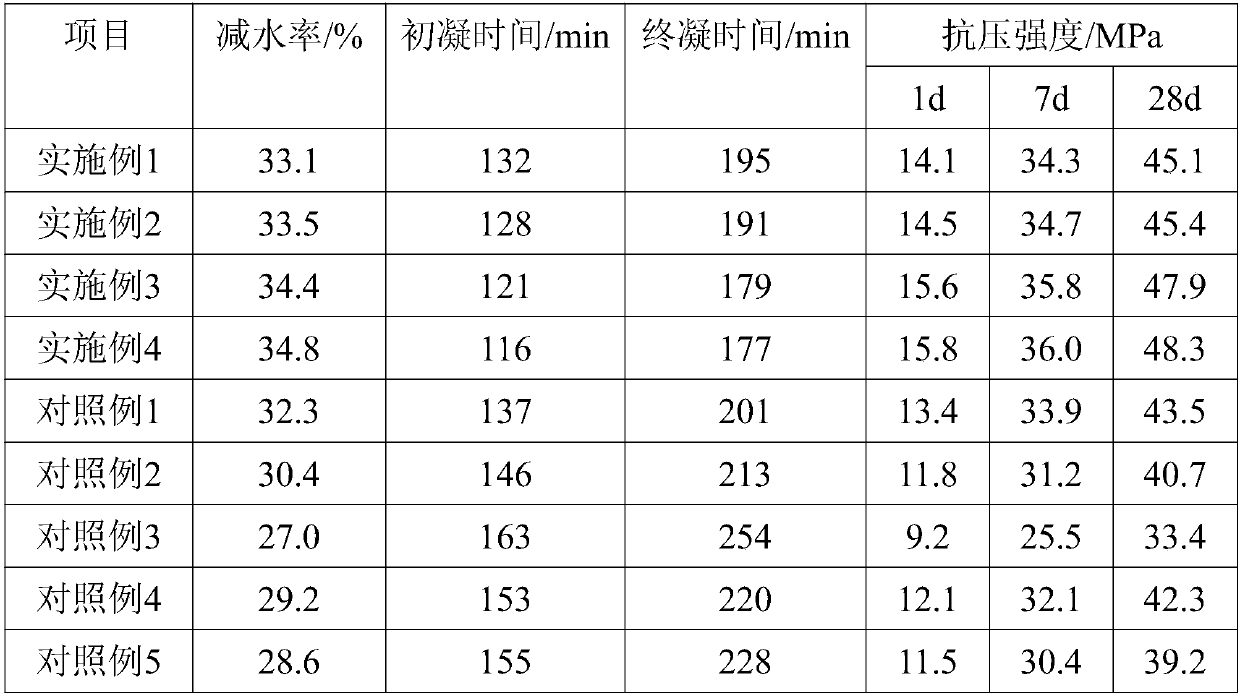

Embodiment 1

[0037](1) Add water to 20g of soil-grade polyglutamic acid and 10g of hydrolyzed polymaleic anhydride under stirring until completely dissolved, add dropwise 5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 40g of polyethylene glycol mono Methyl ether 750, add water until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heat to reflux state and keep stirring for 3 hours, the resulting mixture is concentrated under reduced pressure into a paste with a solid content of 45-55%, and the mixture is heated at 5°C / min The cooling speed is lowered to 0-5°C and kept stirring for 30 minutes, and finally sent to a freeze dryer, and the dried solid is made into a fine powder by an ultrafine pulverizer to obtain an ester polymer compound;

[0038] (2) Heat the ester polymer compound to 115-125°C and keep stirring for 5 minutes, add 5g of allyl glycidyl ether and 2g of diacetone acrylamide, continue to keep warm and stir for 30 minutes at 1...

Embodiment 2

[0042] (1) Add water to 15g soil-grade polyglutamic acid and 5g hydrolyzed polymaleic anhydride under stirring until completely dissolved, add dropwise 5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 35g polyethylene glycol mono Methyl ether 750, add water until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heat to reflux state and keep stirring for 3 hours, the resulting mixture is concentrated under reduced pressure into a paste with a solid content of 45-55%, and the mixture is heated at 5°C / min The cooling speed is lowered to 0-5°C and kept stirring for 30 minutes, and finally sent to a freeze dryer, and the dried solid is made into a fine powder by an ultrafine pulverizer to obtain an ester polymer compound;

[0043] (2) Heat the ester polymer compound to 115-125°C and keep stirring for 5 minutes, add 3g of allyl glycidyl ether and 3g of diacetone acrylamide, continue to keep warm and stir for 30 minutes at 115-125°C,...

Embodiment 3

[0047] (1) Add water to 20g of soil-grade polyglutamic acid and 10g of hydrolyzed polymaleic anhydride under stirring until completely dissolved, add dropwise 5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 40g of polyethylene glycol mono Methyl ether 750, add water until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heat to reflux state and keep stirring for 3 hours, the resulting mixture is concentrated under reduced pressure into a paste with a solid content of 45-55%, and the mixture is heated at 5°C / min The cooling speed is lowered to 0-5°C and kept stirring for 30 minutes, and finally sent to a freeze dryer, and the dried solid is made into a fine powder by an ultrafine pulverizer to obtain an ester polymer compound;

[0048] (2) Heat the ester polymer compound to 115-125°C and keep stirring for 5 minutes, add 5g of allyl glycidyl ether and 2g of diacetone acrylamide, continue to keep warm and stir for 30 minutes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com