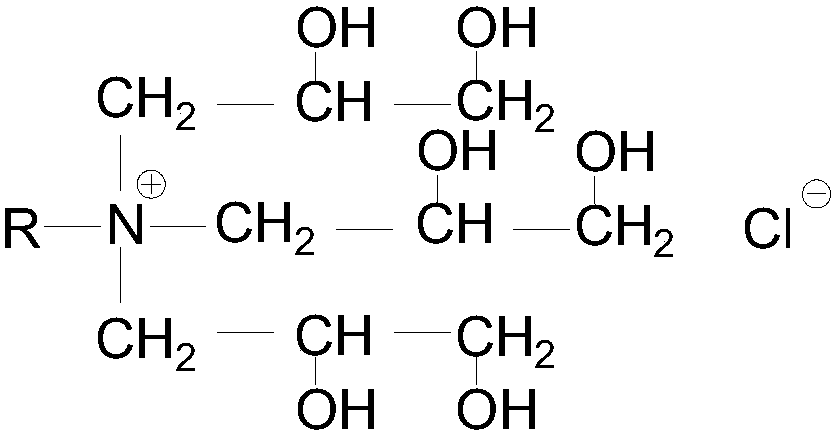

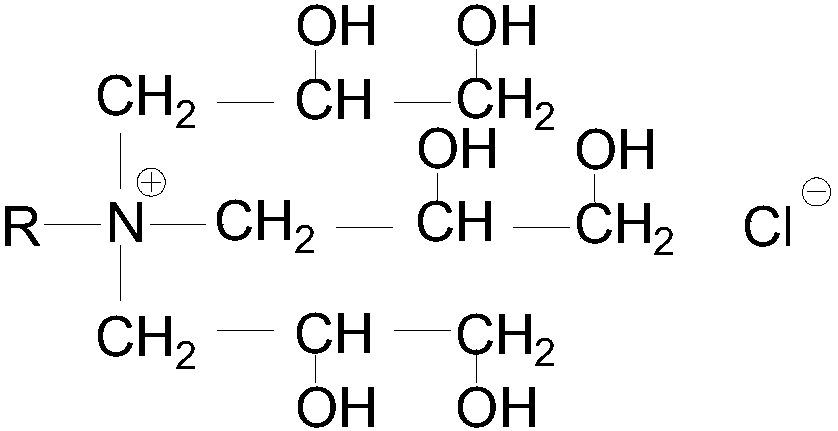

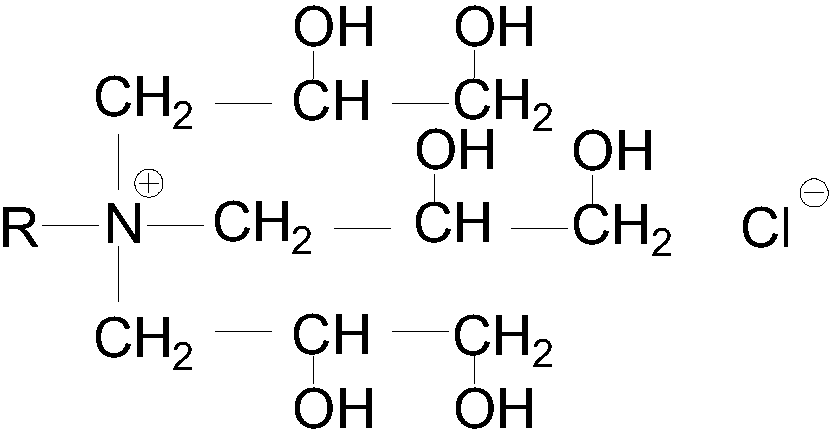

Alkyl polyhydroxy quaternary ammonium salt and preparation method and application of alkyl polyhydroxy quaternary ammonium salt

A technology of alkyl polyhydroxyl and quaternary ammonium salts, which is applied in the field of its preparation, alkyl polyhydroxyl quaternary ammonium salts, can solve the problems of poor water solubility, no moisture retention, poor moisture retention, etc., achieve superior conditioning, solve poor compatibility, The effect of expanding the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Present embodiment is a kind of preparation method of alkyl polyhydroxy quaternary ammonium salt, comprises the following steps:

[0041] (1) In the reactor with agitator, condensing reflux device, oil temperature thermometer control and thermometer in the kettle, drop into lauryl primary amine (C 12 h 25 NH 2 ) and ClCH 2 CHOHCH 2 OH, adding solvent isopropanol, the weight of said isopropanol is C 12 h 25 NH 2 and ClCH 2 CHOHCH 2 15% of the total weight of OH, heat, turn on the condensing reflux device and stir again, the reaction temperature is controlled at 75°C, and the reaction time is controlled at 4h. The reaction formula is:

[0042] C 12 h 25 NH 2 +ClCH 2 CHOHCH 2 OH=C 12 h 25 NHCH 2 CHOHCH 2 OH+HCl

[0043] Stop heating, let it stand still, neutralize HCl with a NaOH aqueous solution with a mass concentration of 20%, separate the liquid, and remove the generated NaCl and H 2 O.

[0044] (2) Press C 12 h 25 NHCH 2 CHOHCH 2 OH and ClCH ...

Embodiment 2

[0052] Present embodiment is a kind of preparation method of alkyl polyhydroxy quaternary ammonium salt, comprises the following steps:

[0053] (1) In the reaction kettle with agitator, condensing reflux device, oil temperature thermometer control and thermometer in the kettle, drop into stearyl primary amine (C 18 h 37 NH 2 ) and ClCH 2 CHOHCH 2 OH, adding solvent isopropanol, the weight of said isopropanol is C 18 h 37 NH 2 and ClCH 2 CHOHCH 2 20% of the total weight of OH, heat, turn on the condensing reflux device and stir again, the reaction temperature is controlled at 85°C, and the reaction time is controlled at 3h. The reaction formula is:

[0054] C 18 h 37 NH 2 +ClCH 2 CHOHCH 2 OH=C 18 h 37 NHCH 2 CHOHCH 2 OH+HCl

[0055] Stop heating, let it stand still, neutralize HCl with a NaOH aqueous solution with a mass concentration of 20%, separate the liquid, and remove the generated NaCl and H 2 O.

[0056] (2) Press C 18 h 37 NHCH 2 CHOHCH 2 OH a...

Embodiment 3

[0064] Present embodiment is a kind of preparation method of alkyl polyhydroxy quaternary ammonium salt, comprises the following steps:

[0065] (1) In the reaction kettle with agitator, condensing reflux device, oil temperature thermometer control and kettle internal thermometer, drop into behenyl primary amine (C 22 h 45 NH 2 ) and ClCH 2 CHOHCH 2 OH, adding solvent isopropanol, the weight of said isopropanol is C 22 h 45 NH 2 and ClCH 2 CHOHCH 2 25% of the total weight of OH, heat, turn on the condensing reflux device and stir again, the reaction temperature is controlled at 75°C, and the reaction time is controlled at 4h. The reaction formula is:

[0066] C 22 h 45 NH 2 +ClCH 2 CHOHCH 2 OH=C 22 h 45 NHCH 2 CHOHCH 2 OH+HCl

[0067] Stop heating, let it stand still, neutralize HCl with 10% KOH aqueous solution, separate the liquid, and remove the generated KCl and H 2 O.

[0068] (2) Press C 22 h 45 NHCH 2 CHOHCH 2 OH and ClCH 2 CHOHCH 2 The molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com