Preparation method of glycyrrhizia polysaccharide with anti-aging activity

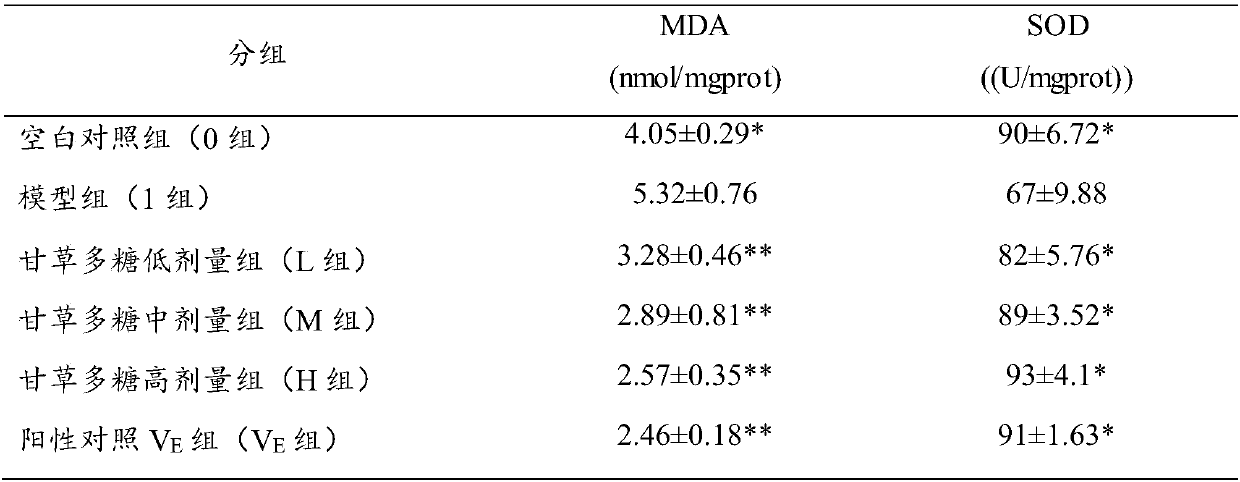

A licorice polysaccharide, anti-aging technology, applied in the field of preparation of licorice polysaccharide, can solve the problems of low polysaccharide activity, high production cost, and inability to industrialize production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

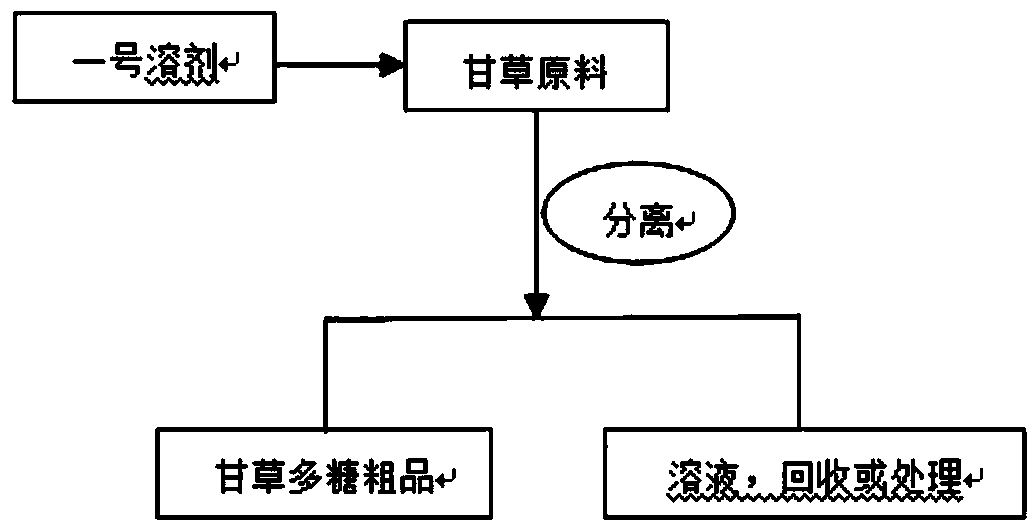

[0027] The invention provides a preparation method of licorice polysaccharide with anti-aging activity, comprising the following steps:

[0028] A) mixing and heating the licorice raw material and No. 1 solvent, and filtering to obtain crude licorice polysaccharide;

[0029] The No. 1 solvent is selected from one or more of phosphoric acid aqueous solution, acetic acid aqueous solution, hydrochloric acid aqueous solution, sulfuric acid aqueous solution, methanol, ethanol, isopropanol and acetone;

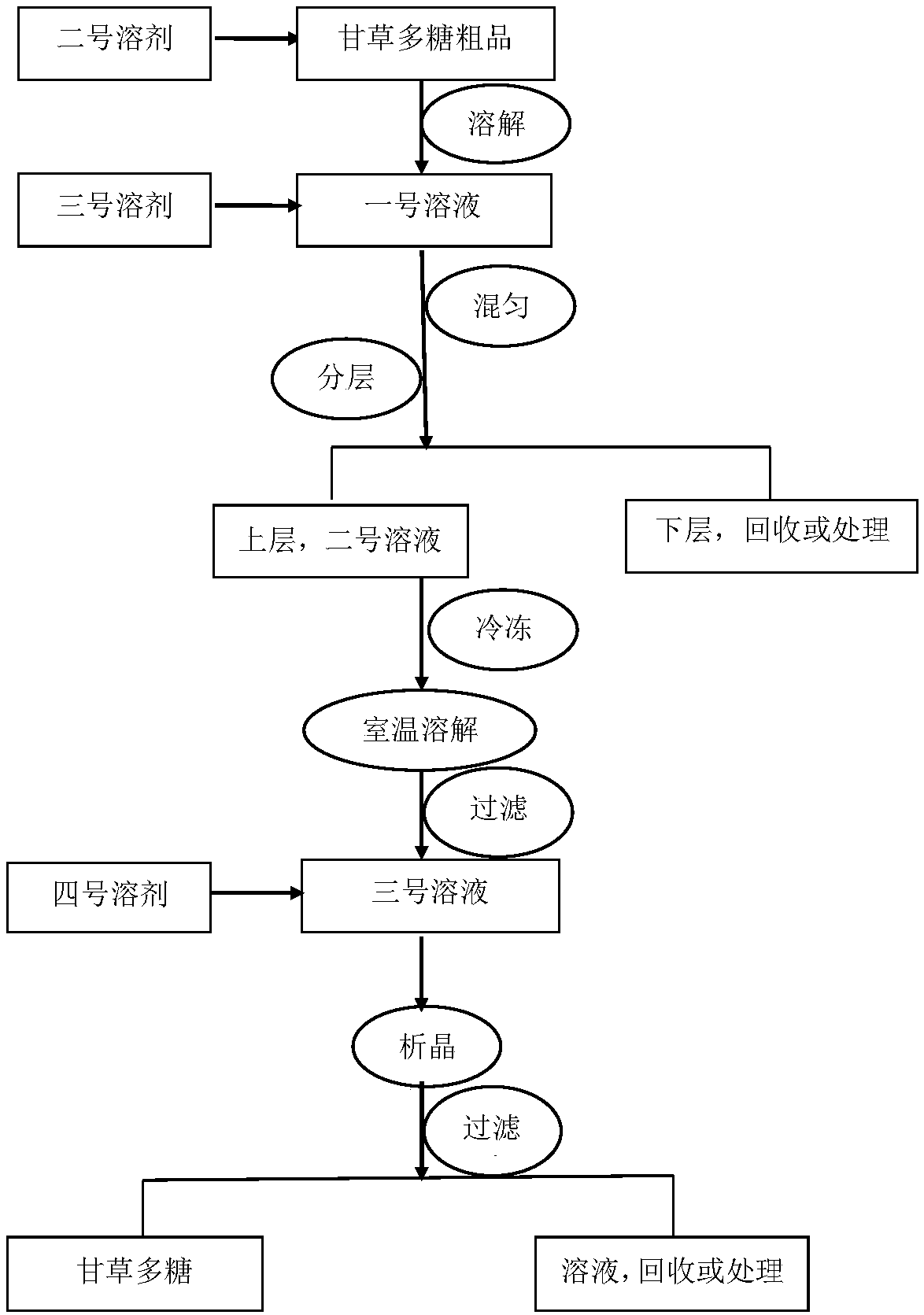

[0030] B) mixing the crude licorice polysaccharide with No. 2 solvent to obtain a mixed solution, adding No. 3 solvent to the mixed solution to mix, standing for stratification, and obtaining a supernatant;

[0031] The No. 2 solvent is selected from water, aqueous ammonia solution, NaCO 3 aqueous solution, NaOH aqueous solution or KOH aqueous solution.

[0032] The No. 3 solvent is selected from the mixed solvent of methylene chloride or methylene chloride and n-butanol;

[0033...

Embodiment 1

[0061] Embodiment 1 prepares licorice polysaccharide

[0062] (1) Separation: Weigh 300g of licorice cream, add 15 times the amount (V / M) (ml / g) of 1% hydrochloric acid ethanol solution, reflux for 1 hour, and filter to obtain insoluble matter, which is the crude licorice polysaccharide;

[0063] (2) Purification: Get the crude product of glycyrrhiza polysaccharide obtained in step (1), add 15 times of amount (V / M) (ml / g) 2% NaOH aqueous solution to dissolve and obtain No. 1 solution, add 6 times to No. 1 solution Volumetric dichloromethane and mixed for 30 minutes, standing for 1 hour, collecting the upper layer to obtain the No. In the amount (V / V) of methanol, an off-white solid was precipitated, which was glycyrrhizic polysaccharide, which was filtered off and dried, and the content of glycyrrhizic polysaccharide was 82.47%.

Embodiment 2

[0070] Embodiment 2 prepares licorice polysaccharide

[0071] (1) Separation: Weigh 300 g of licorice extract powder, add 20 times the amount (V / M) (ml / g) of 1% ethanol hydrochloride, reflux for 1 hour, and filter to obtain insoluble matter, which is the crude licorice polysaccharide;

[0072] (2) Purification: Get the obtained licorice polysaccharide crude product in step (1), add 20 times of amount (V / M) (ml / g) 2% ammonia water solution after dissolving to obtain No. 1 solution, add 3 times to No. 1 solution volume of dichloromethane and mixed for 30 minutes, let the layers stand for 1.5 hours, collected the upper layer to obtain the No. In the double amount (V / V) of ethanol, an off-white solid was precipitated, which was glycyrrhizic polysaccharide, which was filtered out and dried, and the content of glycyrrhizic polysaccharide was 88.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com