Ultraviolet curing super-hydrophobic material used for 3D printing, composition and preparation method thereof

A material composition and 3D printing technology, applied in the field of 3D printing, can solve the problems of poor dirt resistance and poor hydrophobicity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

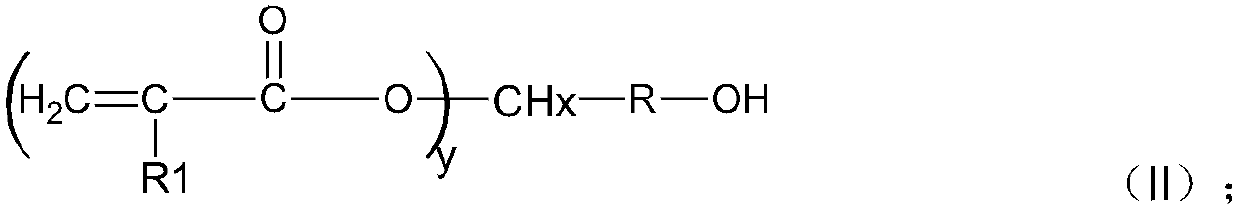

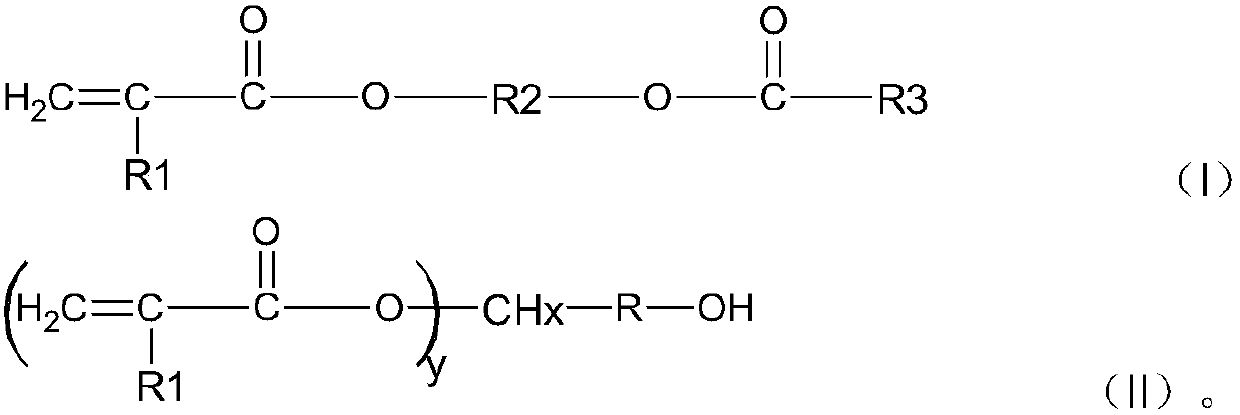

Method used

Image

Examples

Embodiment 1 Embodiment 8

[0060] Embodiment 1 to Embodiment 8 Preparation of UV-cured superhydrophobic materials for 3D printing

[0061] First, mix the oligomer and the diluent in a certain proportion at room temperature, and stir at a speed of 1000-3000r / min for 5-10min to make it evenly mixed. After the system is evenly mixed, add the initiator, part of the defoamer and Stir the remaining additives at the same stirring speed until the initiator is completely dissolved, then add the remaining initiator, stir at a low speed until it is uniform and free of bubbles, store it in the dark for a period of time, and dry it in vacuum at 40°C to constant weight to obtain a UV light for 3D printing. Cured superhydrophobic material, wherein, the ratio of each substance in the preparation process is shown in Table 1.

[0062] The content (kg) of each component in table 1, embodiment 1 to embodiment 8

[0063]

[0064]

[0065] Wherein, auxiliary component is as follows:

[0066]

[0067] Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com