A kind of method for preparing nano-enzyme film in situ

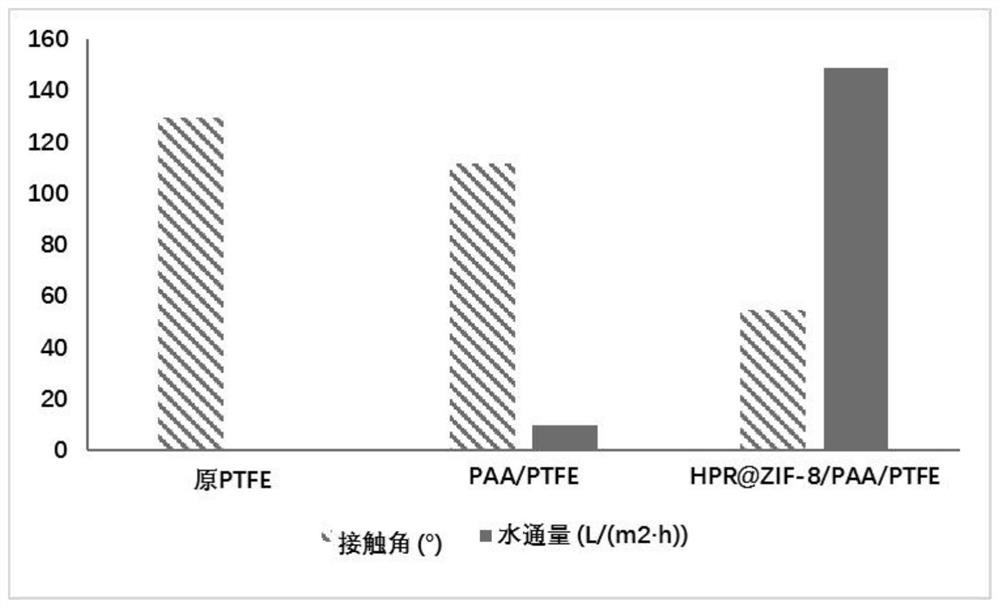

An in-situ preparation and nano-enzyme technology, applied in biochemical equipment and methods, oxidoreductases, enzymes, etc., can solve problems such as difficult to reuse and difficult to recycle, to improve hydrophilic performance, reduce water contact angle, increase The effect of load ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

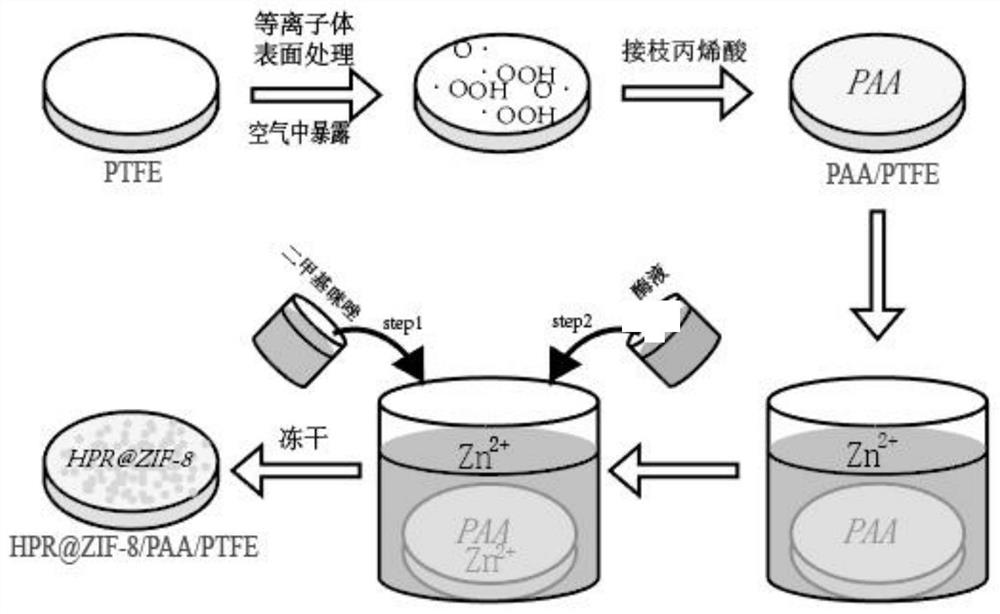

[0024] The preparation method of nano enzyme film of the present invention may further comprise the steps:

[0025] Pretreatment of the original membrane: the original membrane (the original membrane is polytetrafluoroethylene (PTFE) membrane, polyvinylidene fluoride (PVDE) membrane, polyvinylidene fluoride (PVDF) membrane, polysulfone (PS), polyethersulfone (PES) membranes, etc., and not limited to hollow fiber membranes, flat membranes, and tubular membranes) plasma treatment is performed under a nitrogen atmosphere to generate relatively stable free radicals and active sites on the membrane surface, wherein the time of plasma treatment 1 minute to 10 minutes, the nitrogen flow rate is 0.1L min -1 to 0.5L·min -1 ;

[0026] Graft polymerization on the surface of the membrane: put the pretreated membrane into an acrylic acid solution for static immersion for a period of time, then take it out and place it between two glass plates, and carry out thermal polymerization in a va...

Embodiment 1

[0040] Embodiment 1: Preparation method of precursor solution and organic ligand solution

[0041] Preparation of zinc nitrate solution: dissolve 0.372g of zinc nitrate hexahydrate in 4ml of water, and mix in an ultrasonic bath for 5 minutes; prepare dimethylimidazole solution: dissolve 4.1g of dimethylimidazole in 40ml of pure water, and mix evenly in an ultrasonic bath for 5 minutes.

Embodiment 2

[0042] Embodiment 2: Coordinated self-assembly and in-situ growth of nanozymes on the surface of polytetrafluoroethylene membranes

[0043] Will figure 1 The prepared PAA / PTFE polytetrafluoroethylene grafted membrane was immersed in 4ml of zinc nitrate solution with a concentration of 0.3125mol / L for 20 minutes to utilize the metal ion Zn in the ZIF-8 precursor 2+ Coordination with carboxyl groups on the membrane surface assembles to the surface of the grafted membrane. Add 40ml of dimethylimidazole solution with a concentration of 1.25mol / L to the precursor solution, then immediately add 4ml of horseradish peroxidase solution with a concentration of 7.5mg / mL, co-precipitate at 200rpm for 20 minutes, and then take out the membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com