One-step processing method of polyester fabrics for antistatic electricity and dyeing

A polyester fabric and processing method technology, applied in the field of dyeing and finishing, can solve the problems of long process time, low efficiency, high cost, etc., and achieve the effect of broad application prospects and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

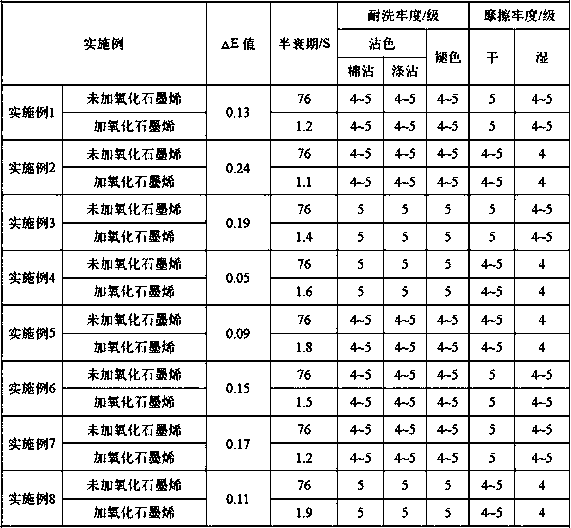

Examples

Embodiment 1

[0017] A kind of polyester fabric antistatic and dyeing one-bath one-step processing method, its process is as follows:

[0018] In the disperse red 3B of 1%owf, the dispersant NNO of 2g / L, the acetic acid of 2g / L, the graphene oxide of 0.005g / L is added in the polyester exhaust dyeing solution that the sodium acetate of 10g / L forms, bath ratio 1: 200, the initial dyeing temperature is 40°C, the heating rate is 1°C / min, the holding temperature is 130°C, the holding time is 40min, then the temperature is lowered to 70°C at 1°C / min, washed with water, 2g / L sodium hydroxide, 2g / L sodium hydroxide 80 ℃ reduction cleaning for 15 minutes, then washing and drying.

Embodiment 2

[0020] A kind of polyester fabric antistatic and dyeing one-bath one-step processing method, its process is as follows:

[0021] Add in 20g / L disperse blue 2BLN, 1g / L dispersant MF, 10g / L anti-swimming agent sodium alginate, 10g / L acetic acid, 1g / L sodium acetate in polyester pad dyeing solution 0.05g / L carboxylated graphene oxide, the temperature of the padding solution is 50°C, the excess rate is 100%, the drying temperature after the padding solution is 80°C, the drying time is 2min, the melting temperature is 190°C, and the melting time is 190°C 3min, then washed with water, 1g / L hydrosulfite, 3g / L sodium carbonate, 90°C reduction cleaning for 5min, finally washed with water and dried.

Embodiment 3

[0023] A kind of polyester fabric antistatic and dyeing one-bath one-step processing method, its process is as follows:

[0024] In the disperse yellow 4RFN of 3%owf, the dispersant NNO of 4g / L, the acetic acid of 10g / L, add the graphene oxide of 0.004g / L in the polyester exhaust dyeing solution that the sodium acetate of 3g / L forms, bath ratio 1: 50, the initial dyeing temperature is 60°C, the heating rate is 2°C / min, the holding temperature is 140°C, the holding time is 20min, and then the temperature is lowered to 70°C at 4°C / min, washed with water, 3g / L sodium hydroxide, 1g / L sodium hydroxide 85 ℃ reduction cleaning for 10 minutes, then washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com